Understanding Automotive Wiring Connector Types

Cars rely on various automotive electrical connectors types to function efficiently. These connectors play a crucial role in maintaining stable and secure electrical connections within the vehicle, ensuring smooth operations. From pigtail connectors to terminal blocks and bullet connectors, each type serves a specific purpose in the automotive wiring system. Proper selection and maintenance of these connectors are essential to prevent issues caused by heat or frequent use, ultimately prolonging the lifespan of car systems. Understanding the significance of these components is key to preserving the overall health and performance of a vehicle's electrical system.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They link different electrical circuits, helping parts talk to each other. These connectors have many shapes and sizes for different jobs in cars. By making strong connections, they keep a car's electrical system working well and safely. Wiring connectors are key parts in car systems.

Importance in Automotive Systems

Car electrical connectors are very important for today's cars. They help send electric signals between systems, powering things like the engine control unit and radio. Without them, car parts would not communicate well, causing problems and safety risks. These connectors show how car technology has improved, making driving smoother. Car electrical connectors are very important for today's cars.

Basic Components of Connectors

Knowing the basic parts of car electrical connectors is important to understand how they work.

Terminals

Terminals are the main part of any connector. They let electricity move between wires by touching each other. Made from copper or brass, terminals conduct electricity well and resist rusting. Their design changes based on use, with some having bigger pins for more power.

Housings

Housings cover the terminals to protect them and give support. They keep terminals in place so they don't disconnect by accident. Housings also organize wires in a car, helping mechanics find connections easily during repairs.

Seals

Seals protect automotive connectors from damage. They stop water, dust, and dirt from getting inside which can cause rust or failures. Seals are crucial where connectors face tough conditions like under a hood or near wheels.

Types of Car Electrical Connectors

Knowing different car connectors is important for fixing cars. Each kind has a special job to keep the car's electric parts working well.

Blade Connectors

What They Are and Do

Blade connectors are also called spade connectors. They have a flat metal piece that fits into a slot. This makes them easy to connect and disconnect. They are used in car lights, batteries, and fuse boxes because they work well.

Who Makes Them

Many companies make good blade connectors. TE Connectivity and Molex are famous for making strong ones. These companies make sure their connectors last long in tough car conditions.

Pin Connectors

What They Are and Do

Pin connectors have pins that fit into sockets for a strong connection. They are used in engine controls and sensors where signals must be clear. Their design keeps signal loss low, which is great for important tasks.

Who Makes Them

Delphi and Amphenol make pin connectors. These companies use precise designs and strong materials to meet modern car needs.

Ring and Spade Connectors

What They Are and Do

Ring and spade connectors join wires to posts. Rings go over bolts for tight connections. Spades have forked ends for easy use. They're common in battery terminals, grounding, and starters because they're reliable.

Who Makes Them

Panduit and 3M make top ring and spade connectors. They offer many sizes so they fit different car uses.

Knowing these connector types helps keep a car's electrical system working right. Picking the right one makes parts last longer.

How to Install Connectors Right

Putting in car connectors right helps them last long. This part shows you how to do it well. install connectors right

Crimping the Right Way

Crimping is key for strong car connections. It means squeezing a connector onto a wire so they stick together well.

Tools You Need

To crimp right, you need these tools:

Crimping Tool: Get a good one that fits your connector and wire size.

Wire Stripper: This tool takes off the wire cover without hurting it.

Multimeter: Use this to check if the connection works after crimping.

Easy Steps to Follow

Take Off Wire Cover: Use the stripper to take off about 1/4 inch of cover.

Put Wire In: Slide the bare wire into the connector hole.

Line Up Connector: Put it in the crimper's jaws just right.

Squeeze Tight: Press hard with the tool to lock it in place.

Look at Crimp: Make sure it's tight and no wires are sticking out.

Check Connection: Use a multimeter to see if it works fine.

Keeping Connections Safe

Safe connections stop problems and keep things working well.

Checking If It's Good

To see if connections are good, do this:

Look at It: Check for damage or rust on parts.

Test Flow: Use a multimeter to make sure electricity moves through.

Try With Load: Test if it can handle power without getting too hot.

Mistakes Not To Make

Avoid these mistakes for better performance:

Too Much Force: Pressing too hard can break things.

Not Enough Force: Weak pressing makes bad connections.

Wrong Connector Type: Using wrong ones can cause issues later. wire connectors types

Ignoring Power Limits: Match connector power limits with what you need.

By following these steps, car connectors will work great and stay safe in cars.

Common Problems and Fixes

Finding Bad Connectors

Signs of Trouble

Automotive electrical connectors can show problems in different ways. You might see lights flicker or electronics act weird. Things like the radio or dashboard lights could stop working suddenly. A burning smell or damage near connectors means they might be too hot or rusty. Spotting these signs early stops more harm to the car's electric parts.

Tools for Checking

To find bad connectors, workers use special tools. A multimeter checks voltage and current to find circuit issues. They also use circuit testers to see if electricity moves right through connectors. For tricky problems, oscilloscopes show electric signals and spot any odd patterns. These tools help fix connector problems well.

Fixing and Repairing

Quick Fixes

When quick fixes are needed, some tricks can help quickly. Electrical tape covers bare wires to stop short circuits. Loose connections can be held with zip ties or clamps for now. Sometimes, using a contact cleaner removes dirt and rust so things work until a real fix is done. These quick fixes keep cars running until better repairs happen.

Long-Term Repairs

For lasting fixes, changing bad connectors is best. Workers pick the right automotive electrical connectors types for each car part. Good installation needs proper crimping and tight connections to avoid future issues. Using dielectric grease keeps moisture away from connectors, making them last longer. By fixing main problems this way, cars stay in good shape.

Picking the right connector is key for a car's electrical system. Good connectors help signals move smoothly between parts, making the system work better. They also make it easier to change or fix things without many repairs.

Using the right connectors can save money on big fixes and keep customers happy.

High-density connectors prepare cars for new uses, keeping signals strong and flexible. Choosing good connectors helps cars run well and last longer.

See Also

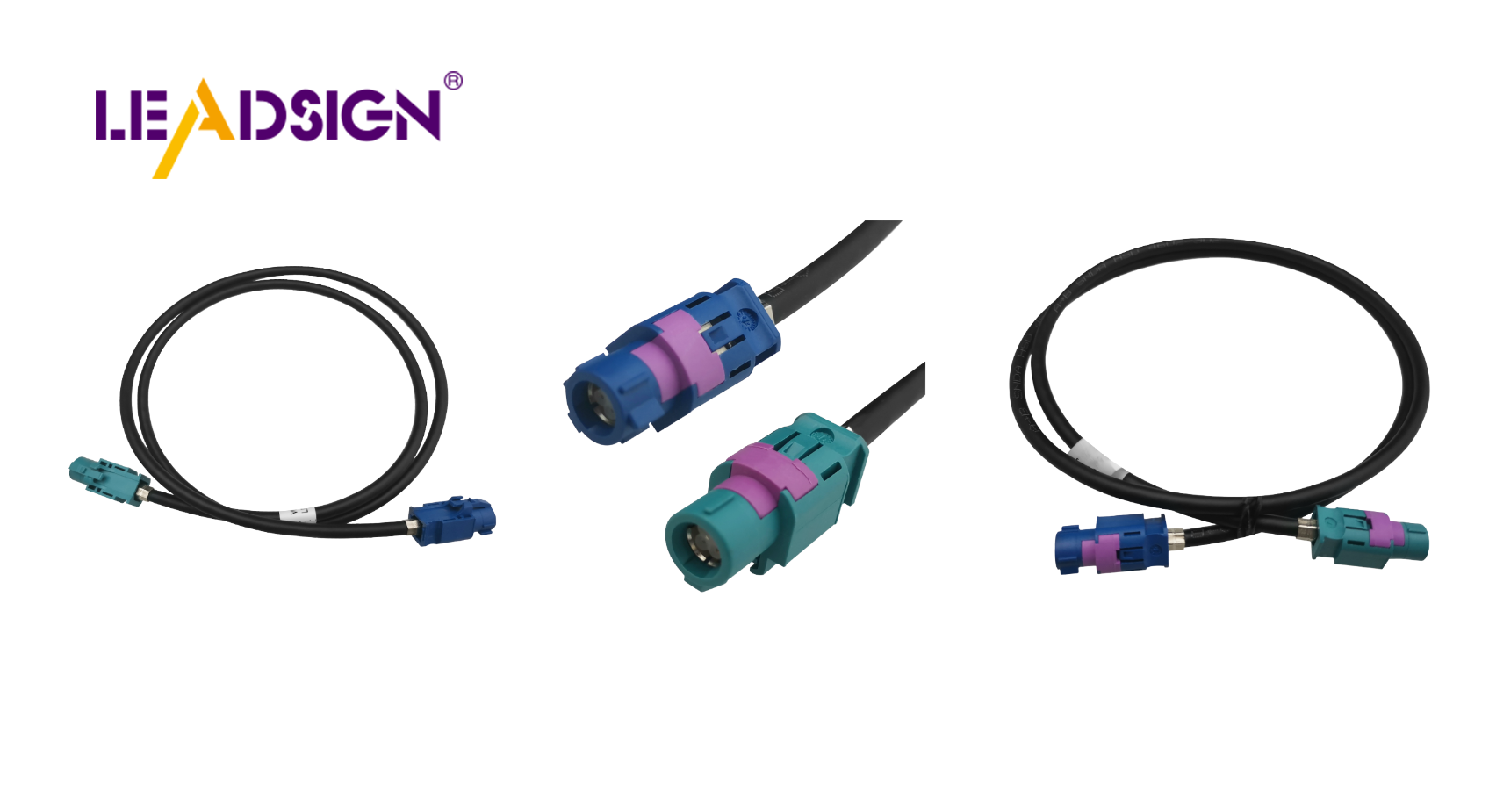

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors