Understanding Automotive Wiring Connector Types

Automotive electrical connectors are crucial in modern vehicles. They facilitate communication between various systems, enhancing both performance and safety. These connectors join wires and cables, providing robust connections for circuits. They also help organize wires, maintaining a neat interior appearance. Utilizing high-quality automotive electrical connectors types ensures durable repairs and optimal vehicle operation. Additionally, these connectors support easy design modifications, troubleshooting, and repairs. In essence, automotive electrical connectors are essential components of car electrical systems, ensuring vehicles operate safely and efficiently.

Blade Connectors

What They Are and How They're Used

Blade connectors, also called spade connectors, are very common in cars. They have a flat metal piece that fits into a slot. This makes it easy to connect and disconnect them quickly. They are great for places where you need to fix or change things often. Blade connectors are usually made of brass or copper, which helps electricity flow well and last long. They often have a plastic cover to stop short circuits.

Where You Find Them in Cars

In cars, blade connectors are used in many parts. They are often found in lights like headlights and taillights because they are easy to install and work well. They also connect things like horns, relays, and switches. Because they work so well and can be used in many ways, they are important for car wiring.

Ring and Spade Connectors

How Ring and Spade Are Different

Ring and spade connectors both attach wires to screws or bolts but look different. Ring connectors make a full circle, so you must take out the screw to use them. This keeps them from shaking loose. Spade connectors look like forks with open ends. You can put them on without taking the screw all the way out, which is good if you need to take them off often.

Tips for Putting Them On Right

To put ring and spade connectors on right, make sure they fit tight so they don't come loose when things shake. Pick the right size for your wire size and check them often for rust or damage, especially if they're near water or chemicals. Use grease to keep rust away.

Butt Connectors

Good Things About Them and Not So Good Things

Butt connectors join two wires end-to-end easily. They're strong once connected but need special tools called crimpers to set up, which might not always be handy. Once joined, you can't take them apart easily.

How To Use Them Best

When using butt connectors, pick the right size for your wire so it stays tight together. Strip the wire carefully so it's not damaged before putting it into the connector; then use crimpers to press it tight together securely. Cover with heat shrink tubing for waterproofing if needed.

Weatherproof Connectors

Why They Matter in Tough Places

Weatherproof connectors are important for cars, especially in tough places. They keep water, dust, and dirt away from wires. This stops rust or breaking. By sealing the wires, these connectors help cars work well even when it's hard outside. This is very important for parts that face rain or mud, like those near the engine or bottom of the car.

Automotive electrical connectors types, such as weatherproof ones, can handle hot and shaky spots. They use strong stuff like gold or tin to stop rusting. This keeps car wires working well for a long time without needing many fixes.

Types of Weatherproof Connectors

There are different weatherproof connectors used in cars. Here are some:

Sealed Connectors: These have rubber parts to block water and dirt. They're used where there's lots of rain or dust, like lights.

Heat Shrink Connectors: When heated, they make a tight seal around wires to keep them dry. They're great where keeping out water is key.

High-Voltage Connectors: Made for hybrid and electric cars, they safely manage high power levels. They fit new tech and updates too.

Pin/Pigtail Connectors: These have colored ends matching wire colors for easy setup and swap-out in cars.

Picking the right automotive electrical connectors types, like weatherproof ones, helps car owners keep their vehicles running well anywhere. These connectors not only guard the wiring but also boost how well the car works overall.

Picking the Right Connector

Choosing the right connector is important for a car's electrical system. The correct one keeps it safe, works well, and lasts long. When picking car connectors, think about a few things.

Things to Think About

Power Needs

Each connector must handle the power it connects to. Too much power can make it too hot and break. So, know how much power and voltage your circuit needs. This helps you pick a connector that handles power safely.

Weather Conditions

Connectors deal with tough weather sometimes. Water, dust, and heat can mess them up. Weatherproof connectors are best for these places. They keep out bad stuff and work well in tough spots. Check where the connector will be used to choose the right one.

Matching with Car Systems

Making Sure It Fits Right

Connectors need to fit with car parts perfectly. A good fit makes sure they work without problems. Look at sizes of both connector and car parts to match them right.

Picking wrong connectors can cause problems. Common mistakes are wrong size or type leading to bad connections. To avoid this, learn what your car needs first. Ask experts or read the car manual for help.

Picking wrong connectors can cause problems. Common mistakes are wrong size or type leading to bad connections. To avoid this, learn what your car needs first. Ask experts or read the car manual for help.

Picking the right car connectors means thinking about many things carefully. By knowing power needs, weather conditions, and matching parts, you make smart choices. This way improves how cars work and makes their systems last longer.

Installation and Maintenance

Installing and taking care of car electrical connectors keeps the car's electric system working well. Here’s a simple guide to help you do it right.

How to Install Properly

Tools You Need

To put in car connectors, gather these tools:

Wire Strippers: They take off wire covers without harm.

Crimping Tools: These attach connectors tightly to wires.

Heat Gun: It helps make waterproof seals with heat shrink connectors.

Multimeter: Checks if connections work and have the right power.

These tools help make strong connections, stopping electric problems.

Easy Steps to Follow

Get Wires Ready: Use wire strippers to remove covers from wire ends. Make sure wires are clean and not broken.

Pick the Right Connector: Choose a connector that fits the wire size and job. Think about weather like heat or wetness when picking.

Attach the Connector: Put the bare wire into the connector and crimp it tight so it stays in place.

Seal It Up: For heat shrink connectors, use a heat gun to seal them waterproof against water or dirt.

Check Your Work: Use a multimeter to check if everything is connected right with good power flow.

Keeping Things Working Well

Spotting Usual Problems

Looking after your car's connectors helps find issues like:

Rusty Parts: Water or chemicals can rust parts, causing bad links.

Loose Bits: Shaking can make connections loose over time.

Broken Covers: Tough conditions can break covers, leading to short circuits.

Finding these early stops bigger issues and keeps cars safe.

Fixes and Tips

To fix and stop connector problems, try these:

Regular Checks: Look for wear, rust, or damage often. Change bad parts quickly.

Protective Grease: Use grease on connectors to stop rust and improve connection strength.

Tighten Everything Up: Make sure all parts are tight. Use locks if you have them for extra safety.

Flexible Connectors: Pick ones that fit what your car needs best for better performance.

By following these steps, car electrical connectors will keep working well, helping your car stay safe and run smoothly.

Choosing the right car connector is very important. Connector Experts say connectors link different car systems. They help power and signals move smoothly. This keeps cars working well. Picking the right connector boosts performance and safety. Regular checks and good setup make them last longer too. Knowing these tips helps car owners keep their cars running safely and well.

See Also

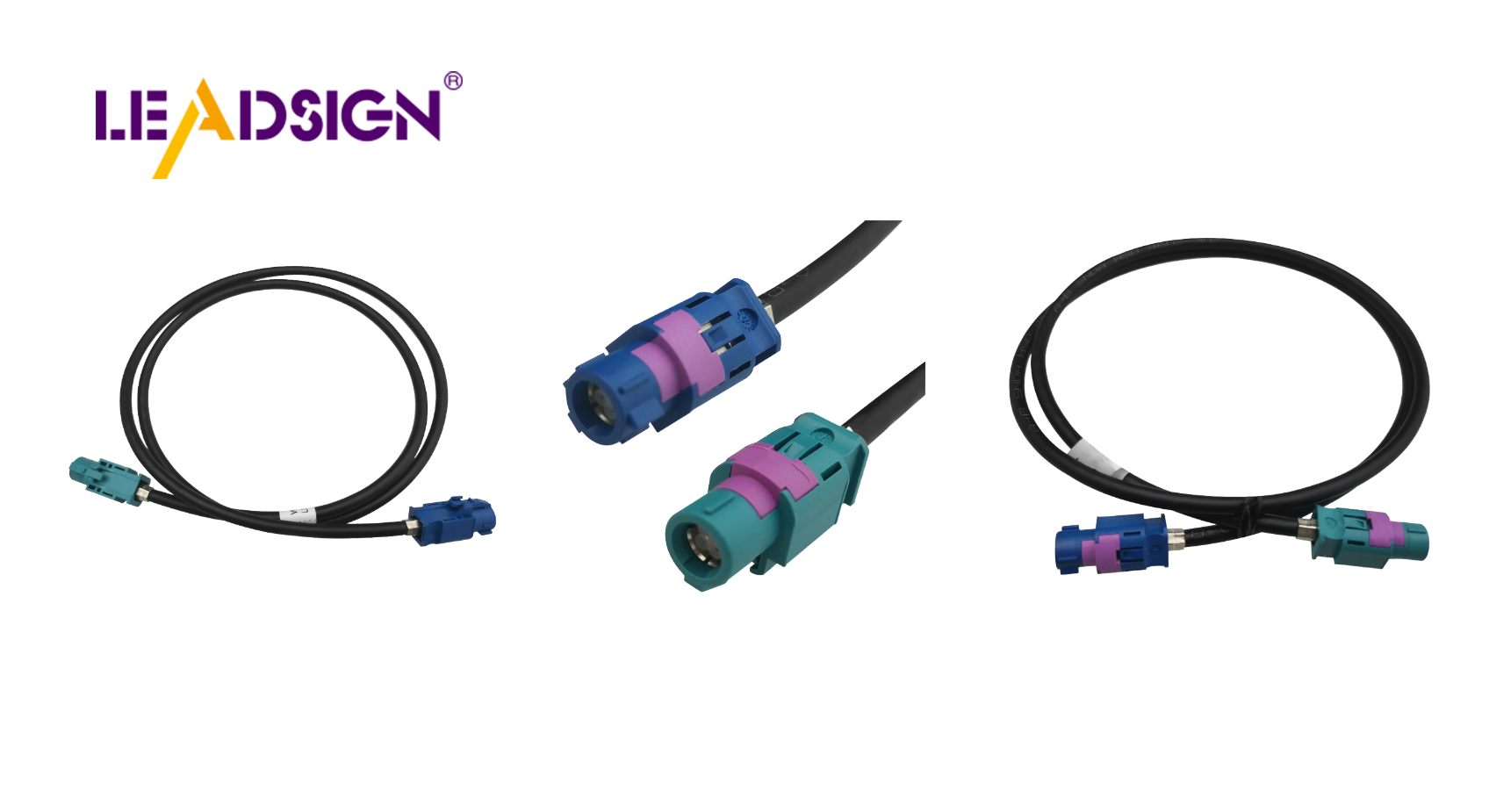

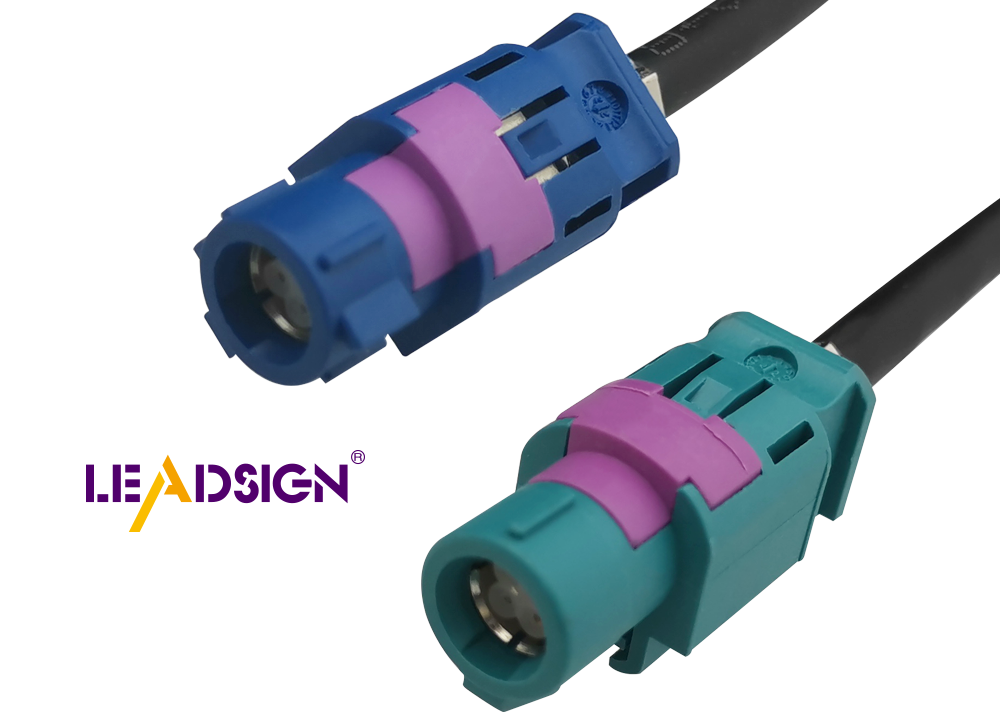

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System