Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in modern vehicles. They facilitate communication and power distribution between components. As vehicles become more technologically advanced, the demand for improved connectors increases. The market for these connectors is projected to grow by 5.8% annually until 2026, reaching $17.047 billion. Understanding the various types of automotive electrical connectors helps individuals maintain and repair vehicles more effectively.

Types of Car Electrical Connectors

Knowing about different car electrical connectors is important for fixing cars. These connectors help parts talk to each other and share power in a car. Let's look at how they are grouped by what they do, how they look, and where they're used.

By What They Do

Power Connectors

Power connectors move electricity from the battery to other parts. They handle lots of power so things like lights and engines work well. These connectors must be strong to stop power problems.

Signal Connectors

Signal connectors send small signals between electronic parts. They are key for sensors and controls that need correct data. These often have many pins for complex signals.

Data Connectors

Data connectors are very important in new cars with digital systems. They help fast data transfer for things like music systems and maps. Automotive electrical connectors types here include USBs, making sure everything connects well.

By How They Look

Male and Female Connectors

Male and female connectors make secure links. The male part fits into the female part, keeping it steady even if the car shakes.

Sealed and Unsealed Connectors

Sealed ones keep out water, dust, and dirt. They're needed in tough spots like near the engine. Unsealed ones work inside where it's cleaner.

By Where They're Used

Engine Area Connectors

Connectors near the engine face heat and liquids. They're sealed to stop rusting and last long for things like fuel systems.

Inside Car Connectors

Inside car connectors link things like radios or air controls. They're easy to put in or fix when needed.

Outside Car Connectors

Outside ones deal with weather so must be tough against rain or dirt. They're used for lights or sensors outside the car.

Knowing these types helps people pick the right connector for each job in a car, keeping it safe and working well.

Standards and Rules

Knowing the rules for car connectors is important. It helps make sure they work well in cars. These rules guide makers to create safe and good connectors.

ISO Rules

ISO makes global rules for car connectors. These rules help connectors work well in different cars. ISO makes global rules

ISO 10487

ISO 10487 is about radio connectors. It helps radios fit into car systems easily. This rule lets radios from different brands work in many cars without problems.

ISO 15170

ISO 15170 is for road vehicle connectors, especially for checking systems. It helps tools talk to car systems well. This rule is key for fixing cars, helping find problems right.

Maker Rules

Car makers have their own connector rules too. These rules make sure connectors fit their cars' needs.

OEM Rules

OEM means Original Equipment Maker rules. They ensure connectors OEM means Original Equipment and systems perfectly. They help save money and keep warranties safe. OEM parts help parts talk and share power better, making cars run well.

Aftermarket Rules

Aftermarket rules are for non-original parts. They ensure these parts fit and work right in cars. They give choices to owners who want new parts without losing quality or performance.

"Global rules are key to future connector growth," says JAE about MX72A/B connectors development. These keep car connectors strong and useful, helping new car needs.

By following these rules, makers and fixers can ensure that car connectors work best, keeping vehicles safe and working fine.

Common Problems and Fixes

Automotive electrical connectors types can have problems that affect cars. Knowing these problems and fixes keeps cars safe and working well.

Connector Problems

Connector problems can stop electricity and data in cars. Finding causes and fixing them stops these issues.

Why They Fail

Corrosion: Water and dirt cause rust, especially in open connectors. Rust blocks electricity flow and harms parts.

Mechanical Stress: Car shaking can loosen connectors, causing weak or lost links.

Poor Quality Materials: Bad materials break easily in tough car conditions, failing early.

Improper Installation: Wrong setup makes loose links or breaks connector parts.

How to Prevent

Use of OEM Connectors: Good OEM connectors fit well and last long. They stop rust and breaking, saving money and keeping warranties safe.

Regular Inspections: Check often for wear, rust, or damage before it gets worse.

Proper Installation Techniques: Follow maker steps to install right, stopping stress for strong links.

Environmental Protection: Use sealed ones where there's water or dirt to stop rusting and make them last longer.

Fixing Methods

When there are problems with automotive electrical connectors types, good fixing methods help solve fast.

Tools for Checking

Multimeters: These tools check voltage, current, resistance to find electric problems in connectors.

Connector Testers: Special testers check if connectors work right.

Visual Inspection: Look closely for visible damage or rust on connectors.

Repair Tips

Cleaning Corroded Connectors: Use cleaners to remove rust and fix connections; dry before putting back together.

Replacing Damaged Connectors: Change broken ones with good OEM parts for trustworthiness.

Secure Connections: Make sure all links are tight; use locks if there are any available.

By solving common problems this way, car experts keep automotive electrical systems safe and running well.

Knowing about automotive electrical connectors types is key for car safety. These connectors help parts talk and share power in cars. Picking the right connector makes cars work better and last longer. Connectors like OEM ones are very reliable. Global rules, like ISO, make sure these connectors fit well in all cars. Learning about these rules helps us keep up with changes in the car world.

See Also

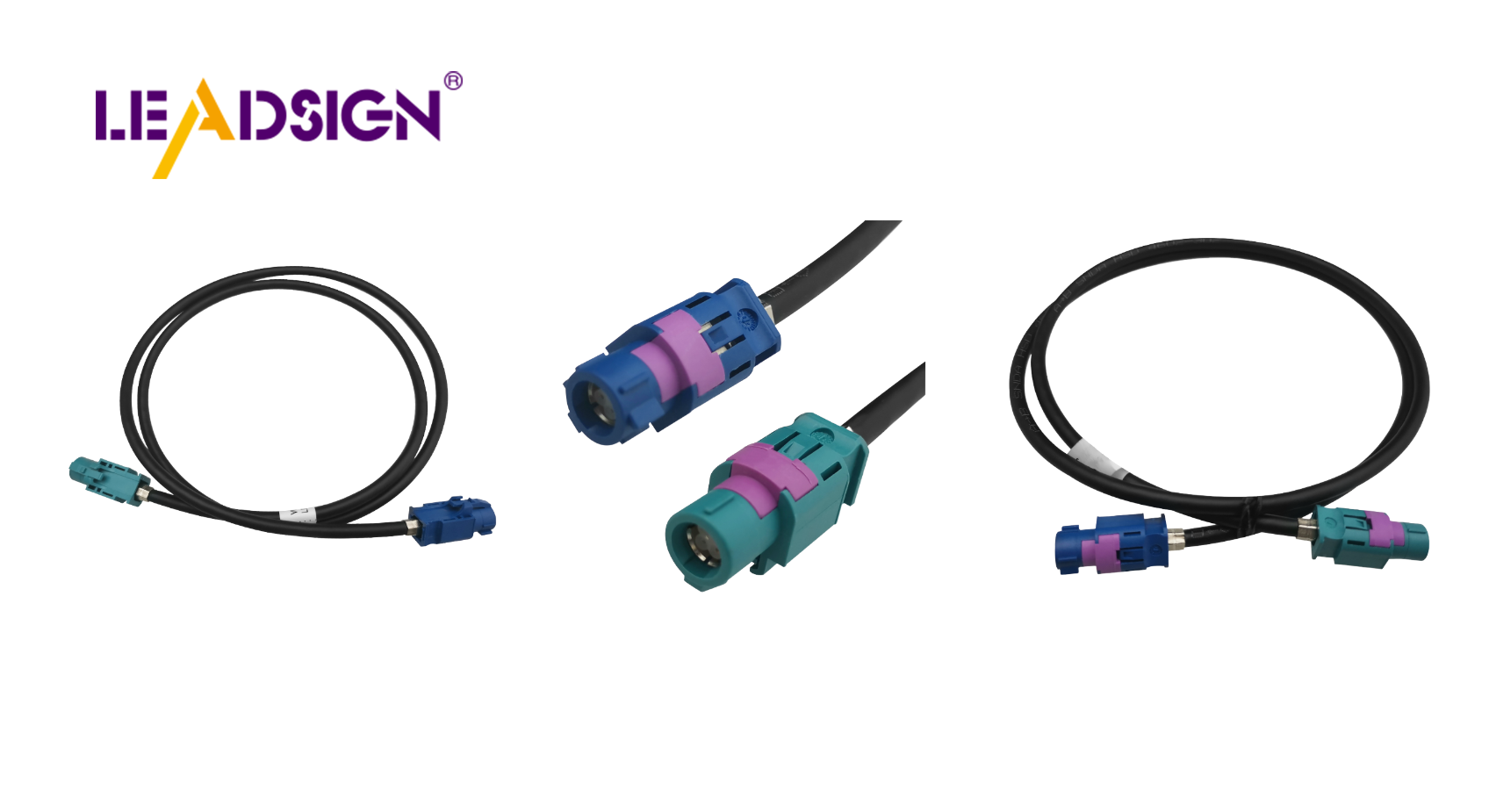

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System