Understanding Automotive Wiring Connector Types

In cars, automotive electrical connectors types are very important. They help car parts talk to each other. Bad connectors can cause electrical problems often. Connectors keep your car's electrical system working well. Car connectors can fail more than airplane wires. Knowing about connector types helps pick the right ones. This makes sure your car works safely and smoothly.

Common Car Electrical Connectors Types

Knowing different common car electrical connectors is important. It helps keep your car's wires working well. Let's look at some common types and what makes them special.

Blade Connectors

What They Are and Where Used

Blade connectors, also called spade connectors, are very common. They have a flat metal piece that fits into a slot. You see these in places needing quick connections, like car radios and lights.

Good and Bad Points

Good Points:

Easy to connect or take apart, great for fixing often.

Stay connected even if the car shakes.

Bad Points:

Not good for high power use.

Can rust if not sealed right.

Ring and Spade Terminals

What They Are and Where Used

Ring Terminals join one wire to another part or wire. They're safe and used a lot in electric work. Spade Terminals have a spade shape that connects with screws. You can take them off without removing screws fully, which is handy for changes.

Good and Bad Points

Good Points:

Ring terminals hold tight, so they don't come loose easily.

Spade terminals are quick to remove, saving time when fixing things.

Bad Points:

Ring terminals need full screw removal to disconnect, which takes time.

Spade terminals might get loose if not tightened well.

Butt Connectors

What They Are and Where Used

Butt connectors join two wires end-to-end in a straight line. They're used in car wiring fixes or setups for strong connections.

Good and Bad Points

Good Points:

Make strong links, perfect for lasting setups.

Simple to use with crimp tools, good for DIY fixes.

Bad Points:

Can't reuse once crimped; need new ones if taken apart.

Might need extra sealing to stop water from getting in.

By knowing these car electrical connectors types, you can choose wisely when fixing your car's wires. Each type has its own pros and cons, so picking the right one keeps everything working well.

Special Car Connectors

In cars, special connectors are very important. They keep the car's wires working well in tough places. These connectors handle things like water and heat, making them very useful.

Weatherproof Connectors

What They Are and Where Used

Weatherproof connectors are used where there's lots of water or dirt. They have seals to stop water from getting in. You find them in engines and outside lights.

Seals: Use rubber rings to keep water out.

Made Of: Often plastic or coated metal that doesn't rust.

Used In: Outdoor lights and engine parts.

Good and Bad Points

Good Points:

Strong: Lasts long even in bad weather.

Safe: Keeps dirt and water away.

Bad Points:

Pricey: Costs more than normal ones.

Hard to Put In: Takes time because of seals.

High-Temperature Connectors

What They Are and Where Used

High-temperature connectors work well in hot places. They're needed near engines where it's really hot. Made from stuff that doesn’t melt or rust easily.

Made Of: Ceramics or plastics that handle heat.

Heat Level: Can take up to 450°C.

Used In: Engine parts and exhausts.

Good and Bad Points

Good Points:

Handles Heat Well: Works even when super hot.

Trustworthy: Doesn't break down easily from chemicals.

Bad Points:

Expensive: Costs more because of special materials.

Not Easy to Find: Harder to get than regular ones.

Knowing about these special car connectors helps you pick the right one for your car's wires. This keeps your car safe and working well, even when things get tough.

Picking the Right Connector for Your Car

Choosing the right car connector is very important. It keeps your car's electrical system working well. Different connectors do different jobs. Picking the right one helps electric signals move smoothly.

Things to Think About

Where They Will Be Used

Think about where you will use the connectors. If your car goes through tough places, like hot or wet areas, choose strong connectors. Weatherproof ones are good for wet spots. High-temperature ones work in hot places like engines.

What Your Car Needs

Check what your car's electrical system needs. Some cars need special connectors, like high-voltage ones for electric cars. Make sure the connector can handle the power needed. This stops it from getting too hot and keeps it working well.

Tips for Putting Them In

Tools You Need

Putting in connectors needs good tools and ways to do it right. Get a good crimping tool to make tight connections. Practice on extra wires first before starting your project.

Crimping Tool: Makes strong connections.

Heat Gun: Helps seal around connectors.

Wire Strippers: Prepares wires before connecting them.

Mistakes to Watch Out For

Watch out for common mistakes when putting in connectors. One mistake is not taking off enough wire cover, which makes bad connections. Another is using a wrong-sized connector, which can be loose or break.

Wrong Wire Stripping: Take off just enough cover to fit snugly.

Wrong Connector Size: Match connector size with wire size.

Too Much Crimping: Use just enough force without breaking it.

By thinking about these things and following these tips, you can pick and put in the right connectors for your car. This keeps your car’s electrical parts working well and safely.

Picking the right car wire connector is very important. The right one keeps your car's wires working well and stops problems. Think about what your car needs and where it goes. This helps you choose the best connector type. Connectors are key to keeping your car running well. By choosing wisely, you make your car safer and better.

See Also

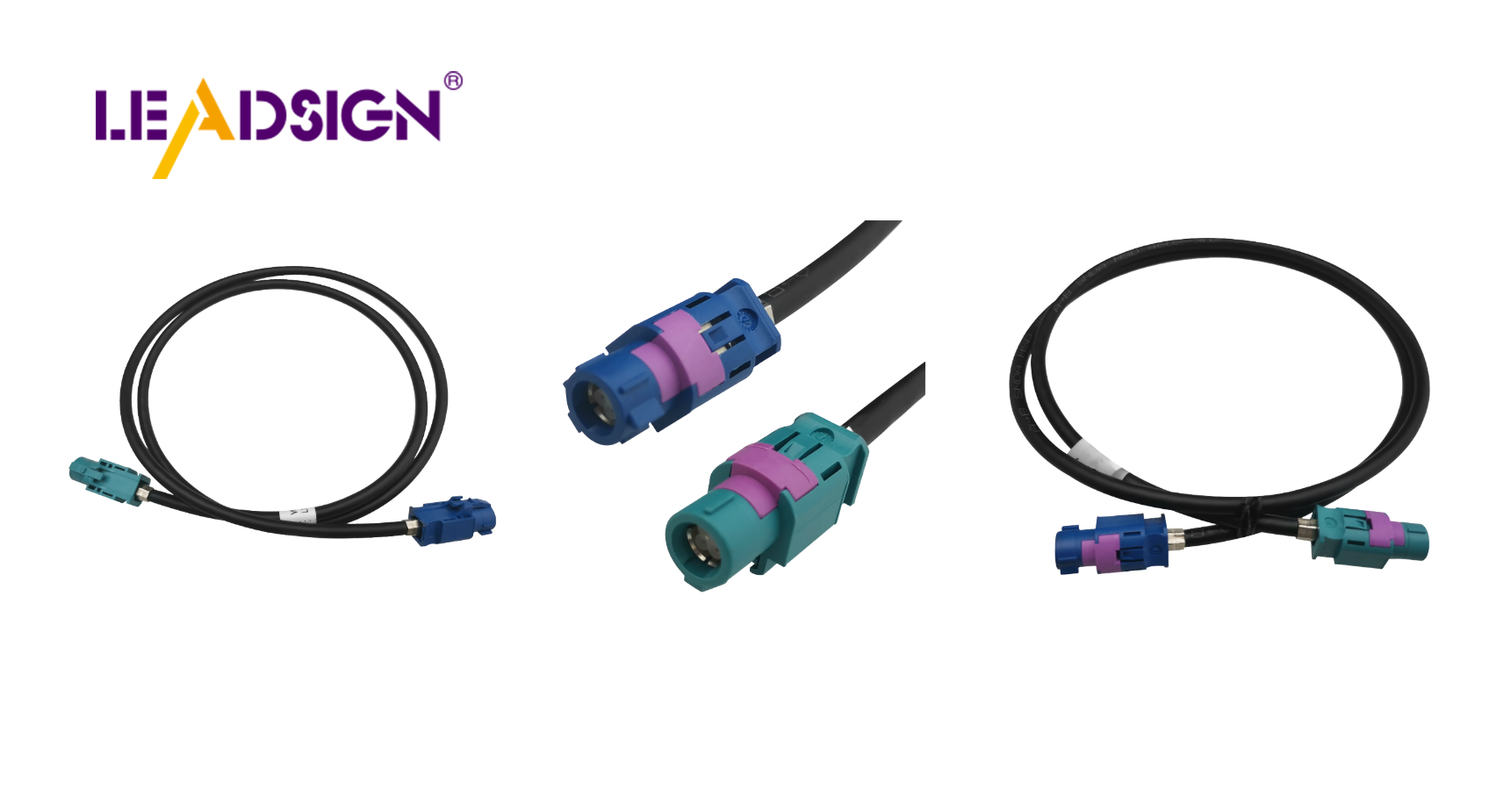

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors