Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles. They play a vital role in ensuring the proper connection of electrical systems. These connectors serve to link various components, enhancing the performance and safety of cars. Selecting the appropriate connectors reduces the risk of malfunctions and prolongs the durability of repairs. The failure rates of different connectors vary based on the levels of heat and power they are designed to withstand. Understanding the diversity of these connectors empowers individuals to make informed decisions for effective car maintenance and safety.

Overview of Automotive Wiring Connectors

Importance of Choosing the Right Connector

Picking the right car wiring connector is key for how well a car works and stays safe. Connectors link different electrical parts, letting electricity flow smoothly. The right connectors make systems work better by giving them the right power and signals. But a bad or wrong connector can cause power loss, signal problems, and bad performance.

Impact on Vehicle Performance

A car's performance depends a lot on good electrical connections. Auto Electrical Connectors join wires to different parts, allowing electricity to power things like lights and engine controls. A strong connection makes sure these systems get the needed power and signals, making them work their best.

Safety Considerations

Safety is very important in cars. Automotive Connectors often face shaking and vibration, especially in big vehicles. They have locks to keep them connected so wires stay linked inside. Many also have strain relief to stop wires from bending too much or breaking at the ends. This design lowers the chance of electrical problems that could make cars unsafe.

Basic Components of a Connector

Knowing what makes up a connector helps choose the right one for each job. Each part has its own job to keep connections strong and lasting.

Housing

The housing holds terminals in place and protects inside parts from things like water, dust, and heat. It often has locks to make it stable and reliable.

Terminals

Terminals are metal pieces inside that connect wires electrically. They fit tightly inside housing, affecting how well electricity flows.

Seals

Seals stop dirt or moisture from getting into connectors, keeping connections safe even in tough conditions.

Types of Automotive Wiring Connectors

Automotive electrical connectors are important for a car's electric systems. Each kind has special uses, benefits, and downsides. Knowing these helps pick the best one for a job.

Blade Connectors

Blade connectors, or spade connectors, are simple and reliable. They are common in cars.

Applications

Blade connectors link wires to things like switches and fuse boxes. They are easy to connect and disconnect when needed.

Advantages and Disadvantages

Advantages:

Easy to use for maintenance.

Stay connected even with shaking.

Disadvantages:

Only good for low power.

Can rust if not sealed right.

Pin Connectors

Pin connectors are tough and flexible. They work well in complex car systems.

Applications

Pin connectors join many wires in systems like engines. They fit lots of connections in small spaces.

Advantages and Disadvantages

Advantages:

Save space with many connections.

Work well in bad conditions.

Disadvantages:

Harder to put together.

Cost more because they are complex.

Butt Connectors

Butt connectors join two wires end-to-end securely.

Applications

Butt connectors fix or extend wires easily without special tools.

Advantages and Disadvantages

Advantages:

Easy to install.

Make strong connections that last long.

Disadvantages:

Not for high power use.

Need the right tools to crimp properly.

Knowing about different automotive electrical connectors types helps keep cars working well. Picking the right one makes sure parts last longer and work better.

Other Types of Car Electrical Connectors

Car electrical connectors come in many shapes. Each type is made for special jobs in cars. Knowing these helps pick the right one, making sure everything works well.

Round Connectors

Round connectors are liked because they are strong and useful. They have a circle shape that holds tight, good for tough places.

Uses: Round connectors work where things need to be very reliable, like near engines. They handle bad conditions like wetness and dirt.

Good Things:

Strong: The round shape fights off weather problems, keeping links strong.

Useful: These can fit different wire sizes, so they work in many systems.

Bad Things:

Hard to Use: Putting them on can be tricky and needs careful fitting.

Pricey: Because they are built tough, they cost more than simple ones.

Many-Pin Sealed Connectors

Many-pin sealed connectors are key in new cars. They keep connections safe and steady for complicated systems. They have lots of pins inside a closed cover to block dirt.

Uses: These are used in important parts like engine controls. Their closed design keeps connections safe even when it's rough outside.

Good Things:

Safe: The seal stops water and dirt from messing up the link.

Space-Saving: Many wires can connect in one spot, making wiring easier.

Bad Things:

Set Up Time: Installing them takes care to keep the seal good, which takes time.

Check Often: If the seal breaks, it can ruin the connection, so check often.

Common Problems and Fixes

Finding Bad Connectors

Automotive connectors link car parts. They help power and signals move smoothly, keeping cars working well. Spotting bad connectors is key for car safety and performance.

Signs of a Bad Connector

Bad connectors show clear signs. You might see flickering lights or lose power sometimes. Electronic parts may not work right. These problems mean weak connections. Sometimes, the car won't start or acts weird.

How to Test Connectors

Testing shows if connectors are okay. Use a multimeter to check voltage and resistance for any issues. Look closely for rust, breaks, or loose parts too. Regular checks keep connectors in good shape.

Tips for Installing Right

Good installation makes connectors last longer and work well. Doing it right stops future problems.

Needed Tools

You need some tools to install connectors:

Wire cutters

Crimping tool

Heat shrink tubes

Multimeter

These tools make sure connections are strong.

Steps to Install

Get Wires Ready: Cut off wire covers with wire cutters.

Pick the Right Connector: Choose the best connector type.

Attach the Connector: Use a crimping tool to fix it tight.

Cover the Connection: Use heat shrink tubes to keep out water.

Check the Connection: Use a multimeter to test it’s good.

Keeping Connectors Working Well

Regular care keeps connectors from failing.

Inspection Tips

Look often for problems early on. Check for wear, rust, or damage on connectors. Make sure all are tight and secure.

Troubleshooting Steps

To fix problems, do this:

Look Closely: Check for visible damage or rust.

Check Connections: Ensure all are seated tightly.

Use Multimeter: Measure voltage and resistance.

Change Bad Connectors: Replace any that fail quickly.

Knowing these helps keep cars running safely and well by taking care of their connectors properly.

Knowing different car wiring connectors is important for keeping cars safe and working well. Picking the right connectors helps make strong connections that last longer. Fixing or changing bad connectors on time stops problems and makes cars run better. Learning about new connector technology helps people choose wisely, keeping their cars in top shape. Understanding this not only improves car care but also makes driving safer and more reliable.

See Also

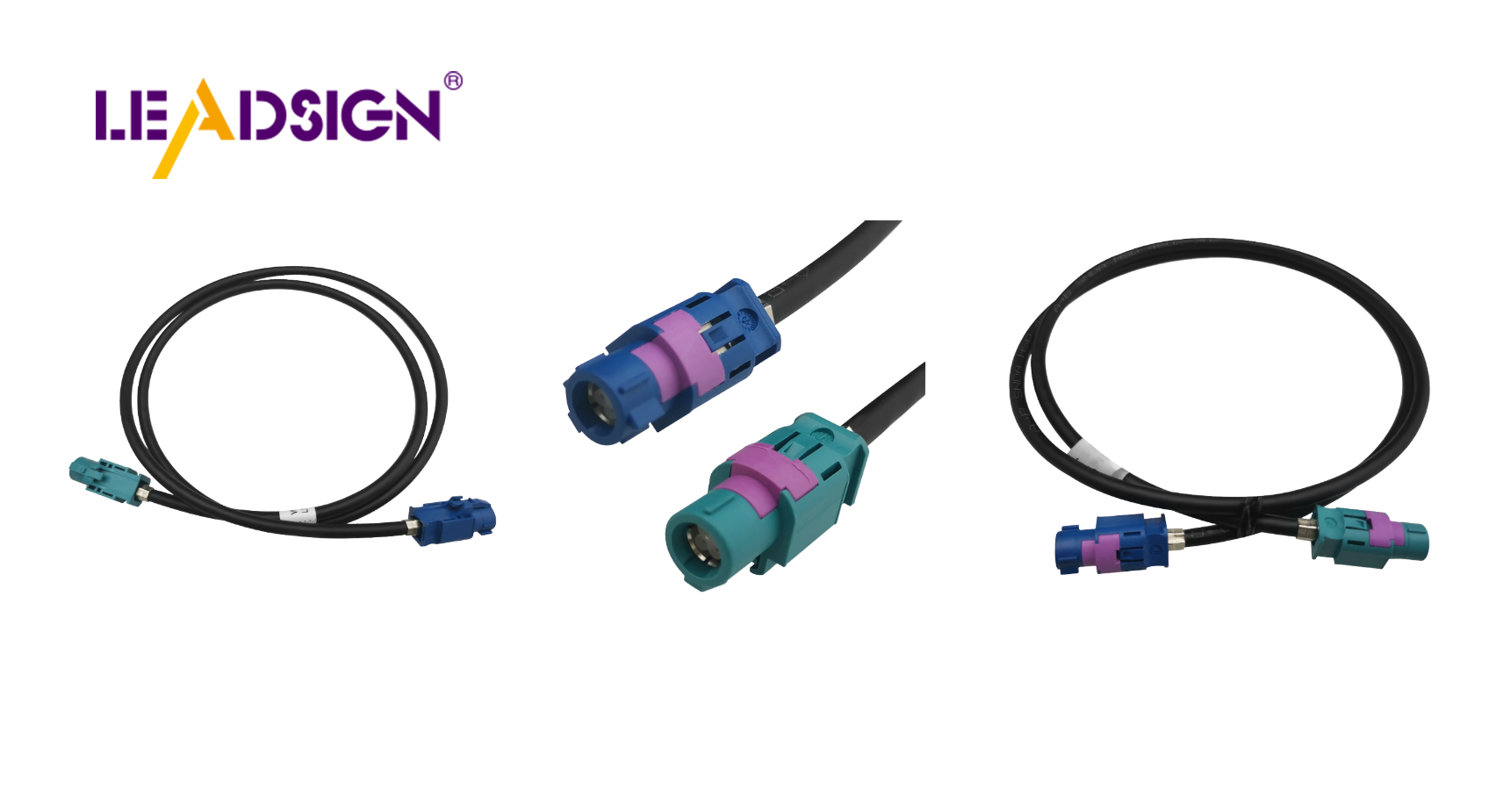

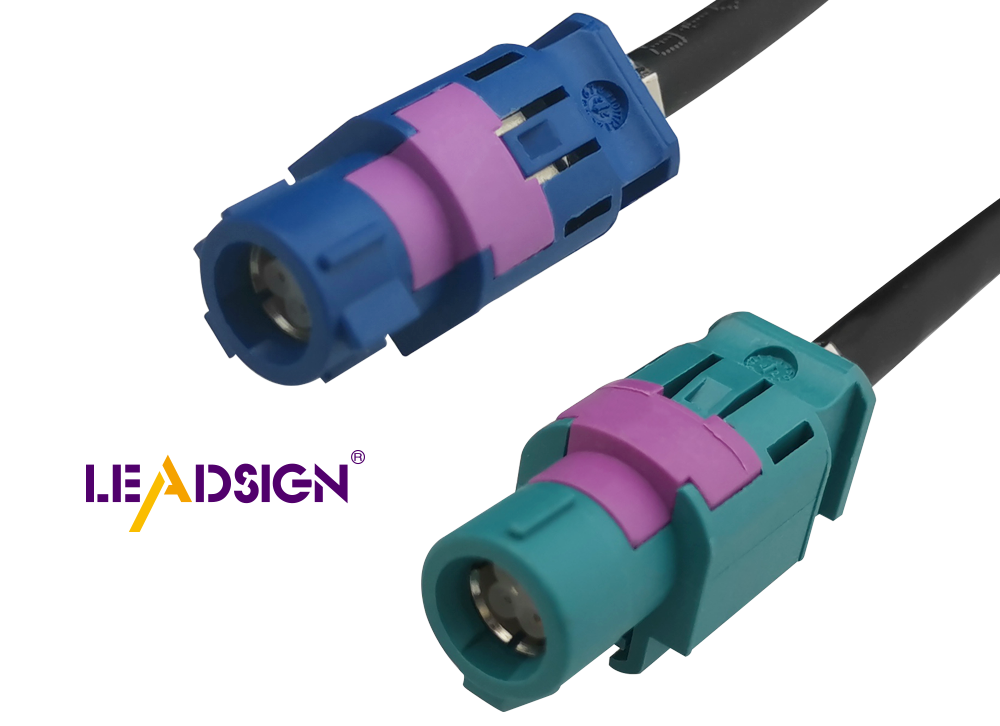

Essential Guide to HSD Connectors in Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors