Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in modern vehicles. They ensure that electrical systems function efficiently and safely by securely joining various components, thereby preventing issues that could lead to costly repairs. These connectors are known to fail 10 to 100 times more frequently than airplane wires, highlighting their significance in automotive safety and performance. Understanding the different types of automotive electrical connectors helps us appreciate their essential role in maintaining seamless connectivity within car systems.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are important parts in cars. They link electrical circuits so signals and power can move easily through a car. These connectors help systems like the engine control and radio work well. By connecting different circuits, they keep electrical links strong.

Importance in Automotive Systems

In cars, wiring connectors are very important. They stop electrical problems by making sure connections are good. Without them, cars would have many electrical troubles, costing lots to fix. Their job of sending signals across systems shows how key they are for car safety and performance.

Basic Components of Connectors

Contacts

Contacts are the main part of any connector. They make the physical link for electricity to pass through. Made from materials that conduct electricity, contacts help send signals well. Their design cuts down resistance, boosting connector performance.

Insulation

Insulation covers contacts to guard against shorts and outside harm. It stops wires from touching when they shouldn't, lowering failure risks. Different materials are used for insulation but all aim to make connectors last longer and be safer.

Housing

The housing holds contacts and insulation together, giving support. It shields inside parts from damage and weather effects. Housing comes in different designs to fit various different connector types, making sure they work with different car systems.

Types of Automotive Wiring Connectors

Knowing different automotive electrical connectors is important for fixing cars. These connectors help signals and power move smoothly in a car. Let's look at some common connector types used in cars.

Blade Connectors

Blade connectors are very popular in cars. They have a flat metal piece that fits into a matching slot.

Applications

Blade connectors are used in many car parts like fuse boxes, relays, and switches. They connect quickly and easily, which is great when you need to unplug them often.

Advantages and Disadvantages

Advantages:

Easy to plug and unplug

Good for low to medium power

Cheap and easy to find

Disadvantages:

Not good for high power

Can get loose if not tight enough

Pin Connectors

Pin connectors are another key type of automotive electrical connectors. They have round pins that fit into sockets.

Applications

Pin connectors are used in engines, sensors, and important systems. They stay connected well, which is important for delicate electronics.

Advantages and Disadvantages

Advantages:

Strong connections

Good for high power

Resist shaking and movement

Disadvantages:

Harder to set up than blade ones

Cost more because they need precise making

Butt Connectors

Butt connectors are simple but work well as automotive electrical connectors. They join two wires end-to-end.

Applications

Butt connectors are often used in wire bundles or repairs. They're great for joining wires when fixing or adding circuits.

Advantages and Disadvantages

Advantages:

Quick to put together

Make strong, lasting links

Insulated ones keep out water

Disadvantages:

Hard to take apart once joined

Need special tools to attach right

Ring and Spade Connectors

Ring and spade connectors are common in cars. They help make strong connections in a car's electrical system. These connectors attach wires to screws or studs, giving a solid link.

Applications

Ring and spade connectors are used a lot in cars. They work where a strong connection is needed. For example, they connect battery ends, grounding spots, and other important parts of the car's electrical system. Their design makes them easy to put on and take off, which is good for places needing regular checks or changes.

Battery Terminals: Ring connectors join battery cables to battery ends. This keeps power steady for the car.

Grounding Points: Both ring and spade connectors make grounding links. These are key for electrical parts to work right.

Fuse Boxes: These connectors also hold wires tight in fuse boxes, stopping them from coming loose by accident.

Advantages and Disadvantages

Ring and spade connectors have many good points but some downsides too.

Advantages:

Secure Connections: Ring connectors wrap around screws fully, making disconnections less likely.

Ease of Use: Both types are simple to install or remove, handy for frequent maintenance needs.

Versatility: Available in different sizes and materials for various uses.

Disadvantages:

Limited Flexibility: Once set up, moving ring connectors is hard without taking them off first.

Potential for Corrosion: Without proper cover, these can rust easily, especially in tough conditions.

Characteristics and Standards

ISO Standards for Connectors

Why Standards Matter

Standards are very important for car connectors. They make sure connectors are safe and work well. This helps cars run without problems. When makers follow these rules, their connectors fit in many cars, lowering the chance of issues. Standards also help sell products worldwide by meeting global quality levels.

Common Standards Used

Many rules guide making car connectors. The International Organization for Standardization (ISO) gives key guidelines. For instance, ISO 6722 tells how strong car wires should be to handle tough conditions. Another rule, ISO 8092, is about connector size and tests for road vehicles. These rules keep things the same and good across the industry.

Material and Durability

Materials Often Used

The stuff used in car connectors affects how they work and last. Metals like copper and brass are common because they carry electricity well. These metals make up the parts inside connectors that send signals. Plastic or rubber covers protect these parts from damage and stops short circuits. The outer shell, usually made of strong plastic, keeps everything safe inside.

What Affects How Long They Last

Many things change how long car connectors last. Good materials help them stay useful longer; strong metals and covers do this best. Weather changes or wetness can hurt them too. Connectors built for tough spots have extra coatings or seals to protect them more. Putting them in right and checking them often also helps them work well over time.

Installation and Maintenance

Setting up and taking care of automotive electrical connectors makes them last longer. This part gives simple steps and tips for doing it right.

How to Install

Tools You Need

To put in automotive electrical connectors, you need special tools:

Wire Strippers: Take off wire covers without harm.

Crimping Tool: Attach connectors tightly to wires.

Screwdriver Set: Tighten screws on ring and spade types.

Multimeter: Check if the connection works well.

Easy Steps

Get Wires Ready: Strip about half an inch of cover from wire ends.

Pick Connector Type: Choose the right one like blade, pin, or ring.

Connect It Up: Put stripped wire in connector. Crimp it tight so it stays connected.

Check Connection: Use a multimeter to see if it's working right.

Make It Secure: For ring or spade types, tighten with a screwdriver on terminals.

Keeping Them Working

Looking after your car's connectors stops problems and keeps things safe.

Regular Checks

Look Over Them: Check often for wear, rust, or damage. Loose parts can mean trouble.

Keep Them Tight: Make sure all connections are snug to avoid failures.

Cleaning Tips

Clean Carefully: Use a soft brush or air to clear dust away. Don't use water or strong cleaners that might hurt them.

Stop Rusting: Put some grease on them to keep out wetness and rust. This helps them work better for longer.

By following these easy steps, you can make sure your car's connectors stay in good shape and keep everything running smoothly.

Common Issues and Solutions

Automotive electrical connectors are key for a car's electric system. But, they can have problems that mess up how they work. Knowing these issues and fixes keeps car systems working well.

Troubleshooting Connector Problems

Spotting Bad Connectors

Finding bad connectors stops electric troubles. Look for flickering lights, rust, or breaks. Check them often to catch problems early. Experts say regular checks stop future issues. They advise looking for loose parts or color changes, which show hidden problems.

Fixing Usual Problems

After finding a bad connector, fix it fast. Here are some common fixes:

Cleaning Rust: Use a soft brush to clean rust off connectors. Put grease on them to stop more rust.

Tightening Parts: Make sure all parts fit tight. Loose ones cause flickering signals.

Changing Broken Connectors: If one is too broken, get a new one. Experts say test the new part after putting it in to make sure it works right.

Q&A Section

Common Questions

Why do connectors break?

They break from rust, damage, or wrong setup.

How often should we check them?

Check during regular car care to find problems early.

Can I fix a broken connector myself?

Simple fixes like cleaning or tightening can be done at home but changing them might need help from experts.

Expert Advice

Connector experts say knowing rules and weather helps pick the right automotive electrical connectors. They suggest choosing ones with good IP ratings for better reliability. Design experts stress learning about connector details for top performance.

"Good care and checks stop electric failures," says an Installation Teacher. "This keeps cars safe and running well."

By following these tips and solutions, people can keep their car's electric system strong, making sure it runs smoothly and lasts long.

Picking the right car wiring connector is very important. It keeps the car's electric system safe and working well. Different connectors do different jobs. Choosing the right one stops electric problems and saves money on fixes.

Looking after these connectors helps them last longer and work better. Regular checks are key. An expert once said, "Taking care of them stops electric problems."

By knowing this, people can keep their cars running smoothly and well.

See Also

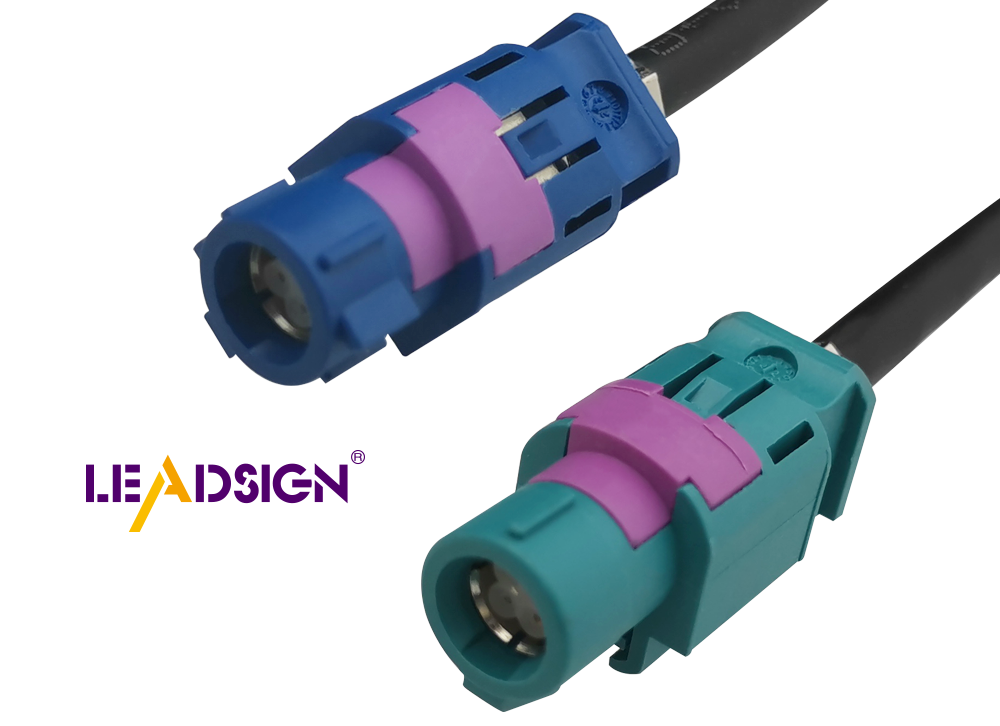

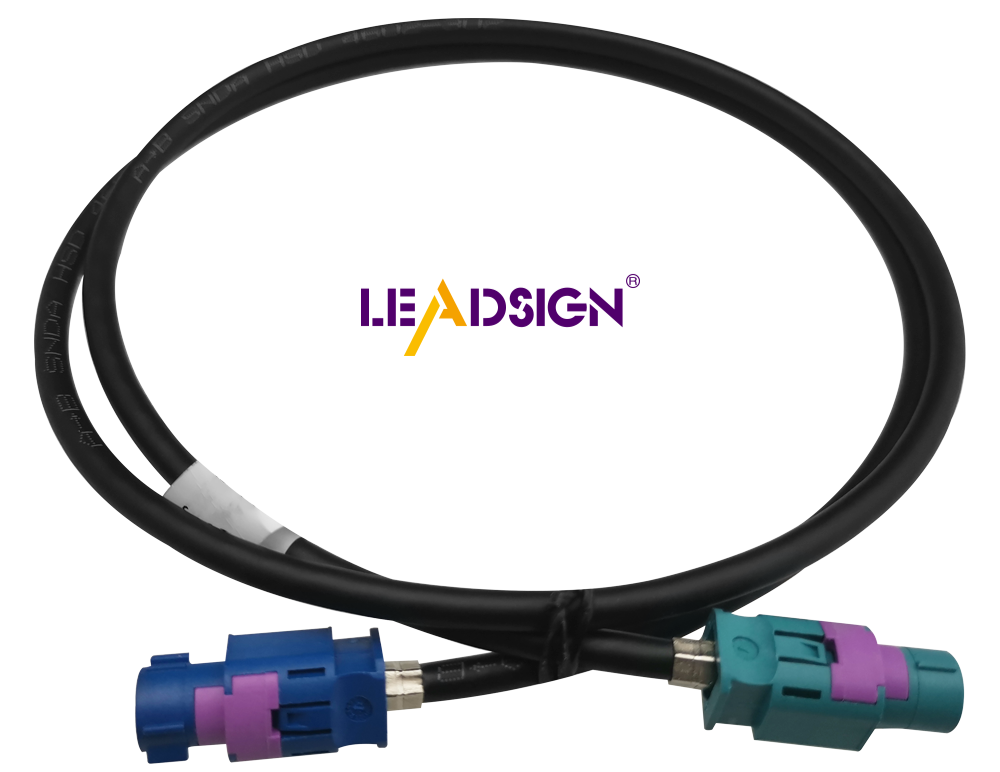

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors