Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial components in modern vehicles. They play a vital role in ensuring the proper and safe functioning of electrical systems in cars. These connectors are responsible for securely linking car wires together, preventing potential electrical malfunctions. Compared to wiring problems, connector failures are more common in automotive systems, underscoring their significance in maintaining the functionality of car systems. Understanding the various types of automotive electrical connectors is essential for effectively repairing and maintaining vehicles.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They join different electronic pieces so they can work together. These connectors have many shapes, sizes, and designs for various electrical jobs. Without them, putting car parts together would be very hard for engineers. wiring connectors

Importance in Automotive Systems

In cars, wiring connectors make sure wires connect well and safely. They stop problems by holding wires tightly. This is important for cars to run safely today. Connectors also help with fast repairs and upkeep, making them must-haves in car systems.

Basic Components

Connector Housing

The connector housing is like a shell that protects inside parts. It keeps terminals safe from things like water and dust. This protection makes connectors last longer. The housing also gives support so it fits well in the car's wiring.

Terminals and Contacts

Terminals and contacts are the main parts of wiring connectors. They make the real connection between wires happen. Terminals are usually made of materials that let electricity flow easily. Contacts keep connections steady, even if there’s shaking or movement. Together, these parts help keep car electrical systems working right.

Types of Car Wiring Connectors

Knowing different car connectors is important for fixing cars. These connectors help car parts talk to each other, keeping the car working well.

By How They Connect

Crimp Connectors

Crimp connectors are common in cars. They hold wires tight by squeezing a metal piece around them. This makes sure wires stay connected and don't come loose. Crimp connectors are liked because they work well and are easy to use. You don’t need to melt anything, so they’re quick to set up.

Solder Connectors

Solder connectors join wires by melting metal around them. This gives a strong connection that lets electricity flow well. Solder connectors are best when you need a long-lasting link. But, they take more time and skill than crimp ones.

By What They Do

Power Connectors

Power connectors handle lots of electricity. They connect things like batteries and engines. These make sure power moves through the car right. Power connectors must deal with heat and shaking.

Signal connectors send information between car parts like GPS or radios. They keep data clear so it works right. Signal connectors often have covers to stop interference from messing up signals.

Signal connectors send information between car parts like GPS or radios. They keep data clear so it works right. Signal connectors often have covers to stop interference from messing up signals.

By Their Shape

Male and Female Connectors

Male and female connectors fit together snugly. The male has pins that go into the female’s holes, making a solid link that stays put even if shaken.

Waterproof Connectors

Waterproof connectors keep water out of electrical links in tough spots like near engines. They use seals to block water, making them last longer.

Key Makers and Rules

Top Makers

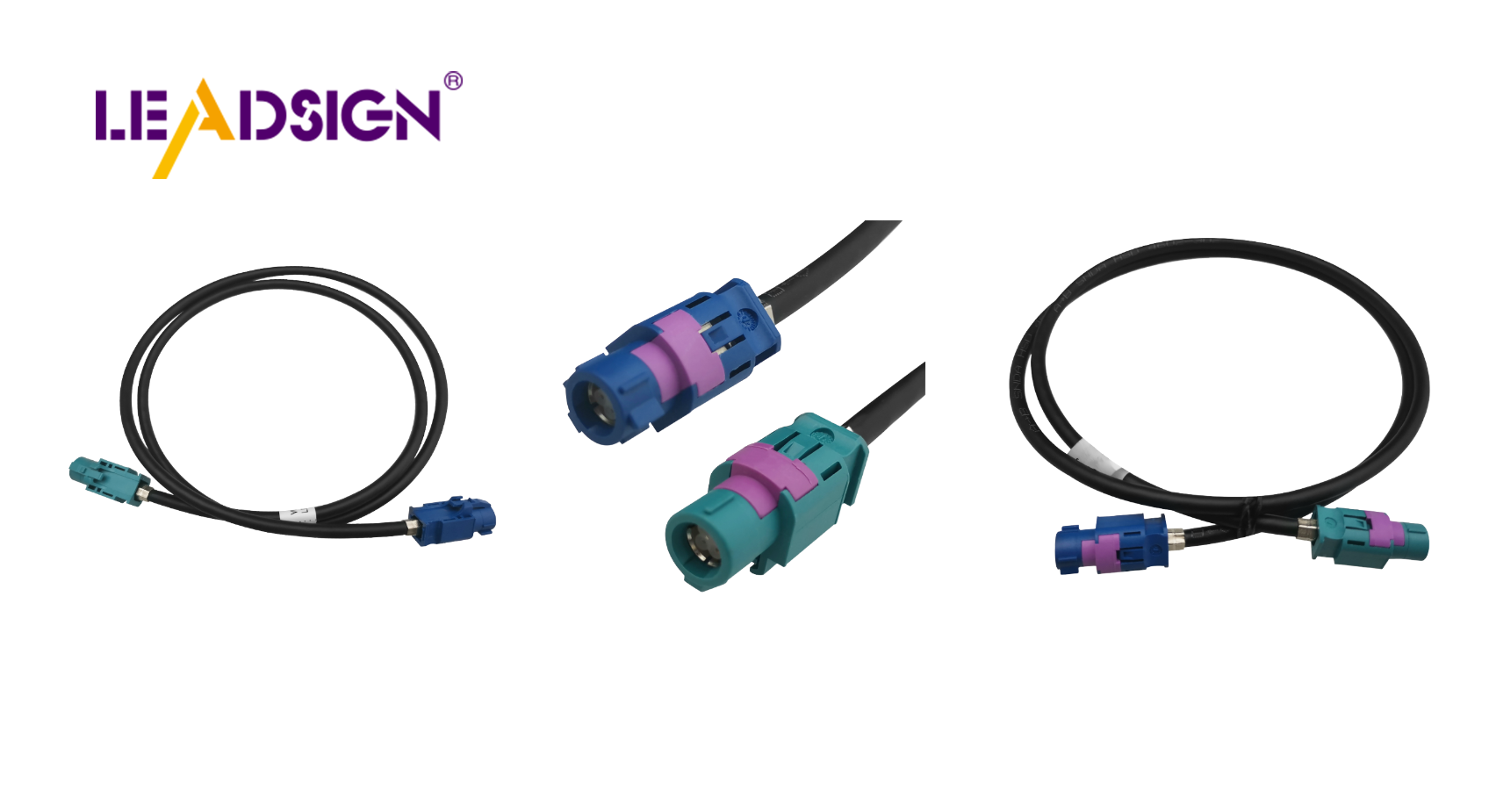

LEADSIGN

LEADSIGN is big in car connectors with its HSD Connector. It helps send fast data in car electronics. It's used for cameras, USBs, and more. LEADSIGN's connectors are strong with good locks and tight wire grips. These make sure they work well even when it's tough.

TE Connectivity

TE Connectivity is a top connector maker known for new ideas. They have over 500,000 products for cars, planes, and networks. Their connectors are trusted for being reliable and efficient. This makes them a favorite for cars. They're on the Fortune 500 list because of their quality.

Industry Rules

ISO Rules

ISO sets world rules for car connectors to be safe and good. These rules help make sure connectors fit different car systems well. By following ISO rules, makers show their products are safe and high-quality.

SAE Rules

SAE gives special rules just for cars about making and testing connectors. These rules make sure connectors handle hard conditions like heat or shaking. Following SAE rules is key to making strong car connectors.

How to Install and Fix Common Problems

Best Ways to Install

Crimping the Right Way

Crimping helps wires connect well in cars. Use the right tool for each connector. Strip the wire carefully so it’s not damaged. The wire should fit tightly in the terminal before crimping. Press evenly with the tool to bond them together. Good crimping stops problems and makes connections last longer.

Keeping Connections Safe

Safe connections keep car systems steady. Make sure connectors are locked in place. They should be clean, without dirt or water. Use special grease to stop rust and help electricity flow better. Check often for loose or broken connectors to fix them on time.

Fixing Usual Problems

Finding Bad Connectors

Bad connectors can mess up car systems. Look for rust, color changes, or damage signs. Use a tester to check if electricity flows through it. Loose connectors can cause power issues sometimes. Looking closely and testing finds bad ones so they can be fixed.

Fixing Loose Connections

Loose connections are unsafe for cars. First, make sure they’re seated and locked well. If still loose, replace with a new one might be needed. Use ties or clamps to hold them tight and stop movement that loosens them. Regular checks keep connections safe from electrical troubles.

Choosing the right connector is very important for car wires. Each type of connector does a special job. It keeps connections safe and working well. Picking the right one stops problems and makes cars work better.

"The best connector can really help car reliability."

To keep car wires working, check them often and change bad connectors quickly. Follow good habits to make sure cars run safely and smoothly. This helps avoid electrical troubles.

See Also

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Today's Cars

Navigating Ford Fakra Connectors