Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in modern vehicles. They ensure the smooth flow of electricity, which is essential for the proper functioning of various systems. There are approximately 100 different types of connectors used in the automotive industry, each contributing to the reliable operation of circuits. The demand for these connectors is rapidly increasing due to advancements in safety and efficiency technologies. To ensure durability and longevity, these connectors must be robust and undergo rigorous testing, such as USCAR-2 and VW80000, to guarantee they last throughout the vehicle's lifespan.

Learning About Car Electrical Connectors

Car electrical connectors are important parts in vehicles. They make sure electricity flows safely and well. This part talks about different connector types, showing their features, uses, good points, and bad points.

Blade Connectors

Features and Uses

Blade connectors are often in cars. They have a flat metal piece that fits into a slot. These are used in blocks, sockets, breakers, and wire groups. Insulated Blade Terminals add safety by stopping short circuits.

Good Points and Bad Points

Blade connectors have some good things:

Easy to Use: Fast and simple to connect.

Flexible: Works for many uses.

But they also have problems:

Low Current Limit: Not good for high power.

Loose Connections Possible: Can get loose if not tight.

Pin Connectors

Features and Uses

Pin connectors have a pin that goes into a socket. They are popular in car electrical systems because they work well and are easy to use. You find them in control boxes and sensor links.

Good Points and Bad Points

Pin connectors give:

Strong Connections: Hold wires tightly.

Toughness: Handle shakes and moves.

Their bad points include:

Harder Setup: Needs careful fitting.

More Expensive: Cost more than others.

Ring Connectors

Features and Uses

Ring connectors have a ring end that fits over bolts or studs. They are used for grounding or battery links. These make strong connections.

Good Points and Bad Points

Ring connectors give:

Strong Link: Tightened with nuts or bolts.

High Power Handling: Good for big power needs.

But they also have issues:

Hard to Install: Needs tools to put on.

Can Rust: Might rust if not covered right.

Butt Connectors

Characteristics and Uses

Butt connectors are important in car wiring. They connect two wires end-to-end. This keeps electricity flowing smoothly. There are two kinds: insulated and non-insulated. Insulated ones have a cover to stop water and rust. They work well where there is moisture. Non-insulated ones, often made of brass, are good for high heat and power places without moisture.

In cars, butt connectors are used a lot because they connect wires without soldering. They are handy for quick fixes or changes. Their flexibility makes them useful in both car and factory settings.

Good Points and Bad Points

Butt connectors have many good things:

Easy to Use: Need few tools, like a crimper, for fast connections.

Flexible: Fit different wire sizes for various car needs.

Cheap: Cost less than other types, great for big projects.

But they also have some problems:

Can't Reuse: Once used, can't be reused; this can cause waste if changes happen often.

Weak Links Possible: Bad crimping can make weak links that might fail.

Not Good in Wet Areas: Non-insulated ones don't work well with water or rust.

Things to Think About When Picking Connectors

Picking the right car electrical connectors is important. It helps keep a car's electric system safe and working well. You need to think about different things to choose wisely.

Electrical Needs

Current and Voltage Levels

When picking connectors, know the current and voltage levels. Connectors should handle electricity without getting too hot or breaking. For example, Nylon Insulated Butt Splices can manage up to 600 volts. They are good for high-voltage jobs. This makes sure they safely carry electricity without problems.

Environment Factors

Where connectors will be used matters a lot. Some, like Non-Insulated Butt Connectors, work best in dry places with no moisture worries. Others with covers, like nylon or vinyl, protect against water and rust. These are better for tough spots. This stops rusting and keeps them working well for a long time.

Mechanical Needs

Strength and Material

The strength of car electrical connectors depends on what they're made of. Strong materials like brass or tinned copper conduct electricity well and handle heat. For instance, Nylon Insulated Butt Splices use tinned copper for better strength and conductivity. Picking strong materials helps them last in tough car conditions.

Size and Fit

Size and fit are key when choosing connectors. They must fit in the space available and match the wiring system already there. Car electrical connectors come in different sizes for various wire thicknesses. Getting the right size stops fitting problems and ensures a strong connection.

By thinking about these things carefully, people can pick the best car electrical connectors for their needs, keeping everything running safely.

How to Install Wiring Connectors

Putting in wiring connectors right makes sure cars work well. This part shows the tools you need and steps to follow.

Tools You Need

To put in connectors, get the right tools. These help make strong connections.

Crimping Tools

Crimping tools are needed to join wires and connectors. They squeeze the connector onto the wire tightly. Different crimpers fit different connectors, so pick carefully. Good crimping stops problems and lasts long.

Soldering Stuff

Soldering is another way to join wires. It melts metal to stick wires together well. Soldering needs skill but makes a strong link that handles bumps and weather.

Steps to Follow

Doing things step by step helps make good connections. Here’s how:

Getting Wires Ready

Take Off Cover: Cut half an inch of cover from wire ends with a stripper.

Twist Wires: Twist bare wires together neatly.

Putting on Connectors

Pick Connector: Choose one that fits wire size and job.

Put Wire In: Push wire into connector till it hits metal.

Crimp or Solder: Use crimper or melt solder for tight hold.

Checking Connection

Look Close: See if there are gaps or loose parts.

Pull Test: Gently pull wire to check if it stays put.

Electric Check: Use a meter to see if electricity flows right.

"Car connectors are key for engineers and techs, helping circuits talk by letting current flow."

By using these steps, people can make strong car wiring links that last long and work well with good prep, tool choice, and checks.

Common Questions and Concerns

Fixing Connection Problems

Automotive connectors help electricity flow in cars. But sometimes, they can cause problems. Fixing these issues is important to keep the car working well.

Finding Bad Connectors

Bad connectors stop electricity from flowing right. This can mess up the car's systems. To find these problems, do this:

Look Closely: Check for cracks or rust on connectors. Damaged ones might look broken or have changed color.

Move Test: Gently wiggle the connector to see if it's loose. A good one should stay still.

Test with Meter: Use a multimeter to check if electricity flows through. If it doesn't, there's a break.

Fixes for Usual Problems

When you find a bad connector, fix it fast. Here’s how:

Clean It: Use cleaner to get rid of dirt or rust. This helps make a clear path for electricity.

Make Tight: Tighten any loose parts so they don’t move around.

Swap Out: Change broken connectors with new ones to keep things working well.

Keeping Things Working

Regular care stops many connector problems before they start. Follow these tips to keep them lasting long and working great.

Regular Checks

Checkups help spot trouble early on. Do this:

Plan Checks: Look at all connectors often, especially where there’s lots of use.

Watch for Damage: See if wires are worn out or covers are cracked.

See How It Works: Watch how electrical parts work; odd behavior might mean connector trouble.

Clean and Care

Cleaning and caring for connectors makes them last longer and work better. Try this:

Use Right Cleaner: Use special cleaners made for electric parts to clean without harm.

Keep Dry: Make sure connectors stay dry; water can cause rust and failures.

Store Well: When not using them, put connectors in a safe, dry place away from harm.

"The automotive connector is common for engineers and techs. It helps circuits talk by letting current flow."

By knowing common troubles and doing regular care, techs can make sure automotive connectors work well and help the car run smoothly.

Picking the right car wiring connector is very important. It makes sure electricity flows well in cars. Choosing correctly helps cars work better and stay safe. Installing and taking care of them is also key. Checking them often stops problems like bad connections. One person said taking pictures and changing wires one by one helped fix mistakes during repairs.

"Push the pins until they click," they said, showing how being careful matters.

Readers should share their stories or ask questions to learn more.

See Also

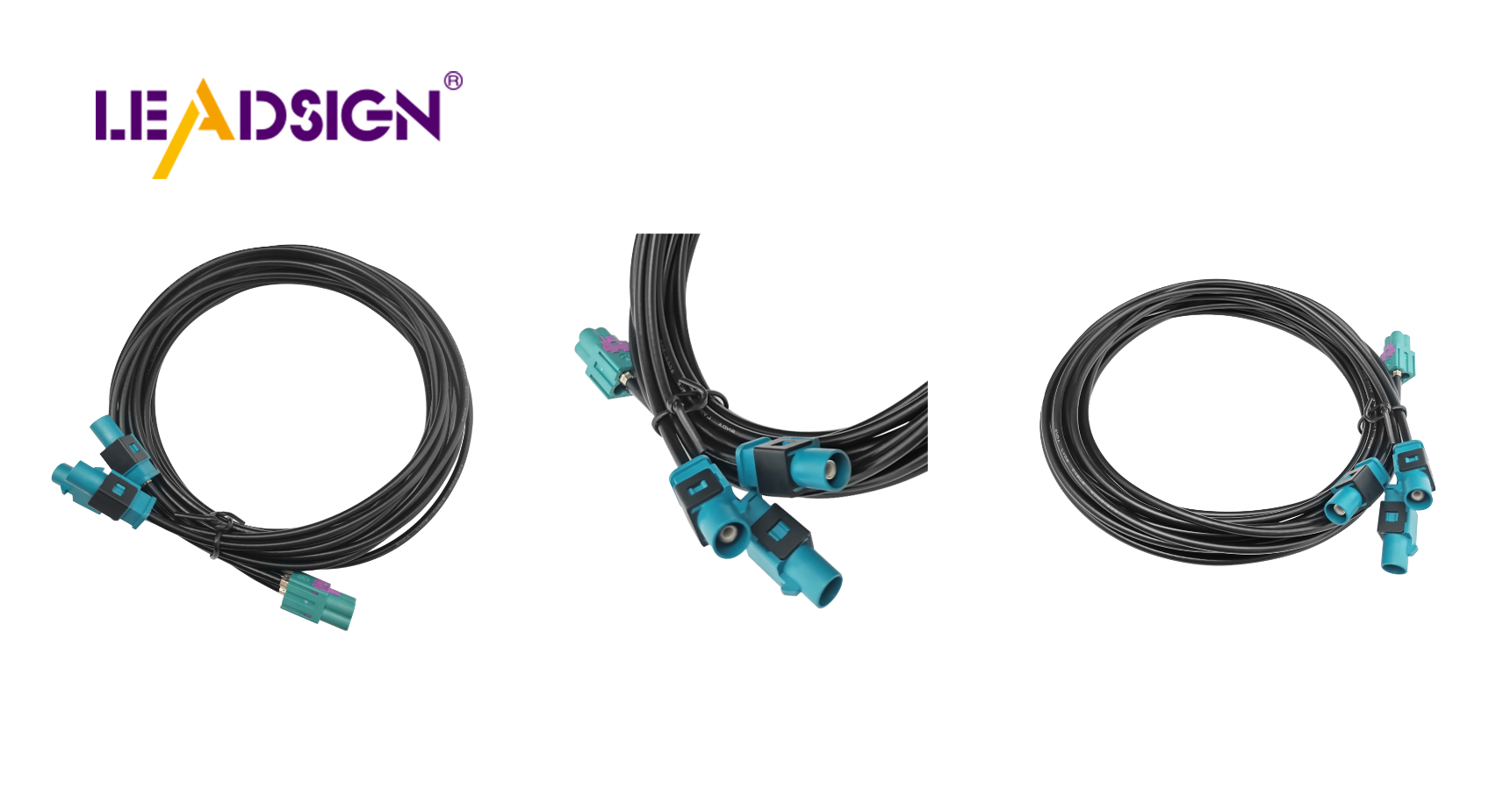

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System