Understanding Automotive Wiring Connector Types

Automotive wire connectors play a crucial role in your vehicle by transmitting electrical signals to various components, ensuring everything functions properly. As vehicles become more sophisticated, the demand for advanced types of wire connectors in automotive applications increases. These connectors are integral to safety systems and crash prevention technologies. Understanding the different types of wire connectors automotive is essential, as they enhance vehicle performance and contribute to ongoing improvements. By recognizing their importance, you can appreciate their impact on driving.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are important parts in a car's electrical system. They connect wires so electricity can move easily between parts. These connectors make sure each part gets the power it needs to work right. Without them, the car's electrical system would be messy and not work well.

Why are they essential in vehicles?

You need wiring connectors to keep your car's wires connected properly. They stop wires from coming loose or breaking, which could cause problems or dangers. By using connectors, you make sure things like lights, starting the car, and music systems work well. This is important for both short trips and long drives.

Historical Evolution

Early designs and materials

In the early 1900s, car connectors were simple and made from things like copper and rubber. These old designs worked but weren't strong or good enough for today's cars. As cars got better, people needed more advanced connectors.

Modern advancements and innovations

Today’s car wiring connectors have changed a lot. Makers use new materials to make stronger and better connectors. Modern ones can handle tough conditions like very hot or cold weather and shaking. They also help with more electronic parts in cars, making sure everything works smoothly from GPS to safety tools. This change shows how much more complex cars have become.

Types of Automotive Wiring Connectors

Knowing different wire connectors helps your car's electricity work well. Each one has its own job and benefits. Let's look at some common types.

Blade Connectors

What they are and where used

Blade connectors, also called spade connectors, are flat metal pieces that fit into slots. They are used in cars for quick connections. You find them in car radios, lights, and other electric parts.

Good and bad points

Blade connectors have good points. They connect well and are easy to use. But they might not stay tight if there's a lot of shaking. Also, they don't protect well against water or dirt.

Pin Connectors

What they are and where used

Pin connectors have a pin and a hole part for strong connections. They're used where steady links are needed like engine controls or sensors. They align easily for connection.

Good and bad points

Pin connectors last long and stay connected even when shaken. They handle strong currents but can be hard to set up because they need exact placement.

Other Common Wire Connectors

Bullet Connectors

Bullet connectors have male and female parts fitting like plugs. They're good for places needing frequent unplugging like car music systems.

Pigtail Connectors

Pigtail connectors join many wires at one spot. They're handy when extending wires or joining different ones, often seen in car wiring fixes.

Terminal Blocks

Terminal blocks link many wires neatly together in cars. They help organize wires for reliable connections.

By knowing these wire connector types, your car's electrical system stays strong and dependable. Each type has special uses, so pick the right one for your needs.

Installation Techniques

Tools Needed

Important tools for setup

To put in car wiring connectors right, you need good tools. Here’s a list of must-haves:

Wire Strippers: These take off the plastic cover from wires without harm.

Crimping Tool: Use this to fasten crimp connectors for a strong hold.

Soldering Iron: This is needed for solder connectors, making a lasting link.

Heat Gun: Use it with heat-shrink tubing to cover and guard connections.

Multimeter: This checks if electricity flows well and everything works fine.

Having these tools makes setting up easier and faster.

Safety steps

Safety is key when working with car wiring. Follow these tips to stay safe:

Disconnect the Battery: Always unplug the car battery before starting work. This stops shocks or short circuits.

Wear Protective Gear: Put on gloves and safety glasses to keep hands and eyes safe from sharp wires and hot items.

Work in Bright Light: Make sure there’s enough light so you can see clearly, lowering mistake chances.

Avoid Wet Areas: Water and electricity don’t mix. Keep your area dry to stop accidents.

By following these safety rules, you can work safely without risks.

Step-by-Step Setup Guide

Getting the wires ready

Getting wires ready is important for good setup. Do these steps:

Cut the Wires: Use wire cutters to make wires the right length.

Strip the Insulation: Take off about half an inch of cover from wire ends using strippers.

Twist the Strands: Twist bare wire strands together for a tidy, solid link.

These steps get wires ready to attach firmly to connectors.

Joining and securing connectors

Once wires are set, connect them securely like this:

Pick the Right Connector: Choose one that fits wire size and use.

Insert the Wire: Put stripped wire end into connector slot.

Crimp or Solder: Use crimper for crimp connectors or soldering iron for solder ones. This step makes sure they hold tight.

Apply Heat Shrink: Slide heat-shrink tube over joint; use heat gun to shrink it tight around connection for cover and protection.

Test Connection: Use multimeter to check flow of electricity; ensure connection is firm.

Following these steps ensures your car wiring connectors are put in right and work well.

Troubleshooting Common Problems

Finding bad connectors

Over time, car wiring connectors can have problems. It's important to find bad ones to keep your car's electrical system working well. Look for these signs:

Loose Connections: Make sure connectors are tight. Loose ones can make power stop and start.

Corrosion: Check for rust or green stuff on connectors that stops electricity.

Physical Damage: Look for cracks or breaks in the connector cover.

By checking these things often, you can find issues early and stop more damage.

Fixing common problems

After finding a bad connector, fix it like this:

Tighten Loose Connectors: Use a tool to make loose connections tight.

Clean Corroded Connectors: Use cleaner to get rid of rust. Dry it before putting back together.

Replace Damaged Connectors: If broken, change it with a new one for good connection.

These fixes help keep your car's wires working well.

Maintenance Tips

Regular check routines

Regular checks keep car wiring connectors in good shape. Do these checks:

Monthly Checks: Look at connectors every month for wear or damage.

Seasonal Maintenance: Before weather changes, protect against water and temperature changes.

Doing these checks helps your connectors last longer.

Best ways to make them last

To help connectors last long, try these tips:

Use Quality Connectors: Buy good quality ones that follow rules.

Proper Installation: Put them in right using correct tools and steps.

Avoid Overloading: Don't use too much power so they don't get too hot.

Following these tips keeps your car's electric parts working well and long-lasting.

Knowing about car wiring connectors is important for your car's electric system. These connectors help electricity move smoothly, so everything works well. By learning the types, you can choose wisely when fixing or adding connectors. This helps your car work better and keeps it safe from things like water and shaking. Always use good connectors to keep your car's electric parts safe and lasting long.

See Also

Exploring HSD Connectors in the Auto Sector

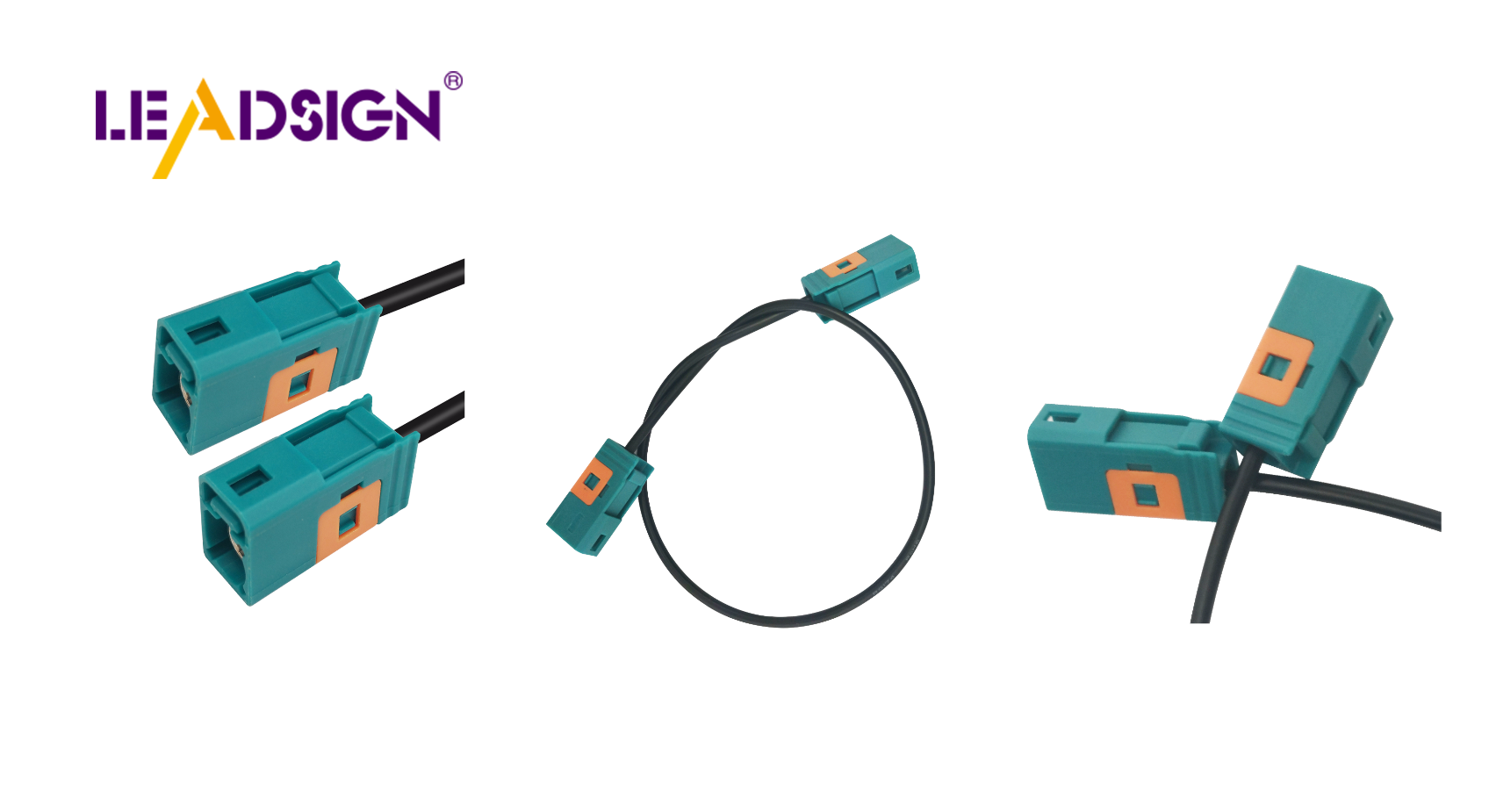

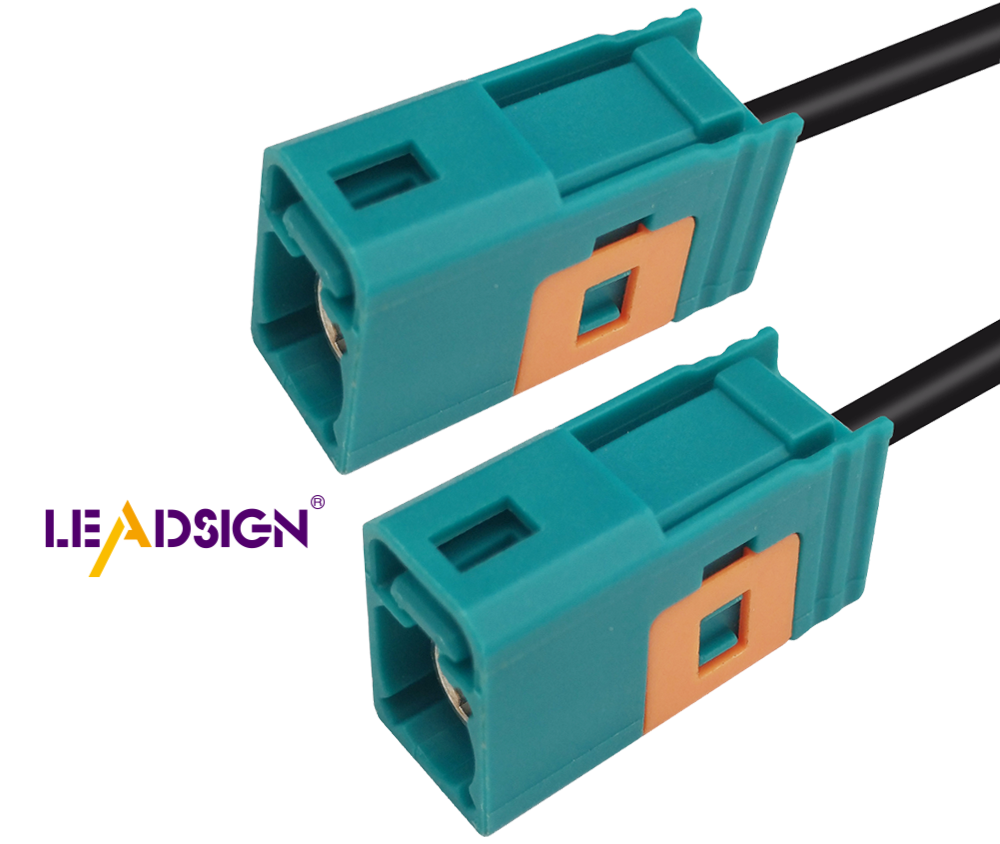

Significance of Fakra Connectors in Today's Cars

Navigating Ford Fakra Connectors