Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial for your vehicle's electrical system. They play a vital role in ensuring proper connections between components, which is essential for the smooth operation of your car. Understanding the various types of automotive electrical connectors is important for making informed decisions when repairing or enhancing your vehicle. Each type of connector has its unique characteristics and may be susceptible to failure from heat or power consumption. By familiarizing yourself with these connector types, you can enhance the performance of your car and maintain its safety.

Early Connector Types

Basic Splice Connectors

Basic splice connectors were used first in car wiring. They were simple and joined wires by twisting them together. A cover kept them safe, but they could loosen over time.

Crimp Connectors

Crimp connectors improved car wiring connections. They used a metal sleeve to hold wires tightly. This made the connection strong and less likely to come apart. Crimp connectors became popular because they were reliable and easy to use.

Modern Connector Types

Quick Disconnects

Quick disconnects changed how we connect wires in cars. They let you separate parts without cutting wires. This made fixing things easier and faster.

Weatherproof Connectors

Weatherproof connectors are for tough conditions like rain or dust. They keep car wires working even when it's wet or dirty outside. These connectors are great for outdoor use.

Future Trends

Smart Connectors

Smart connectors are the future of car wiring. They can send data and help with diagnostics, making cars smarter and safer.

Wireless Connectivity

Wireless connectivity will change car wiring by removing physical connections. It makes adding new tech easier, leading to cool new features in cars.

Automotive Electrical Connectors Types

Knowing different car wire connectors is important. They keep parts connected well, making your car work better and safer. Let's look at some common connector types in cars.

Blade Connectors

Blade connectors are very common in cars. They connect things securely and work well for many uses.

Male Blade Connectors

Male blade connectors have a flat metal piece that fits into a female connector. You see them in fuse boxes and relay panels. They're easy to plug in and take out, which helps with quick fixes.

Female Blade Connectors

Female blade connectors have a slot for the male blade. They fit tightly to stop wires from coming loose. These are important where there’s lots of shaking, like near engines.

Bullet Connectors

Bullet connectors are also popular in cars. They connect wires simply and effectively.

Male Bullet Connectors

Male bullet connectors have a round end that fits into a female connector snugly. They're used in car lights because they stay connected even when things move or shake.

Female Bullet Connectors

Female bullet connectors have a socket for the male bullet end. They hold tight to keep connections safe but are easy to unplug when needed, like for trailer wiring.

Pin Connectors

Pin connectors can be used for many things, including high-power and data signals.

Single Pin Connectors

Single pin connectors have one pin that fits into a socket. They're good for simple jobs like connecting sensors or small parts.

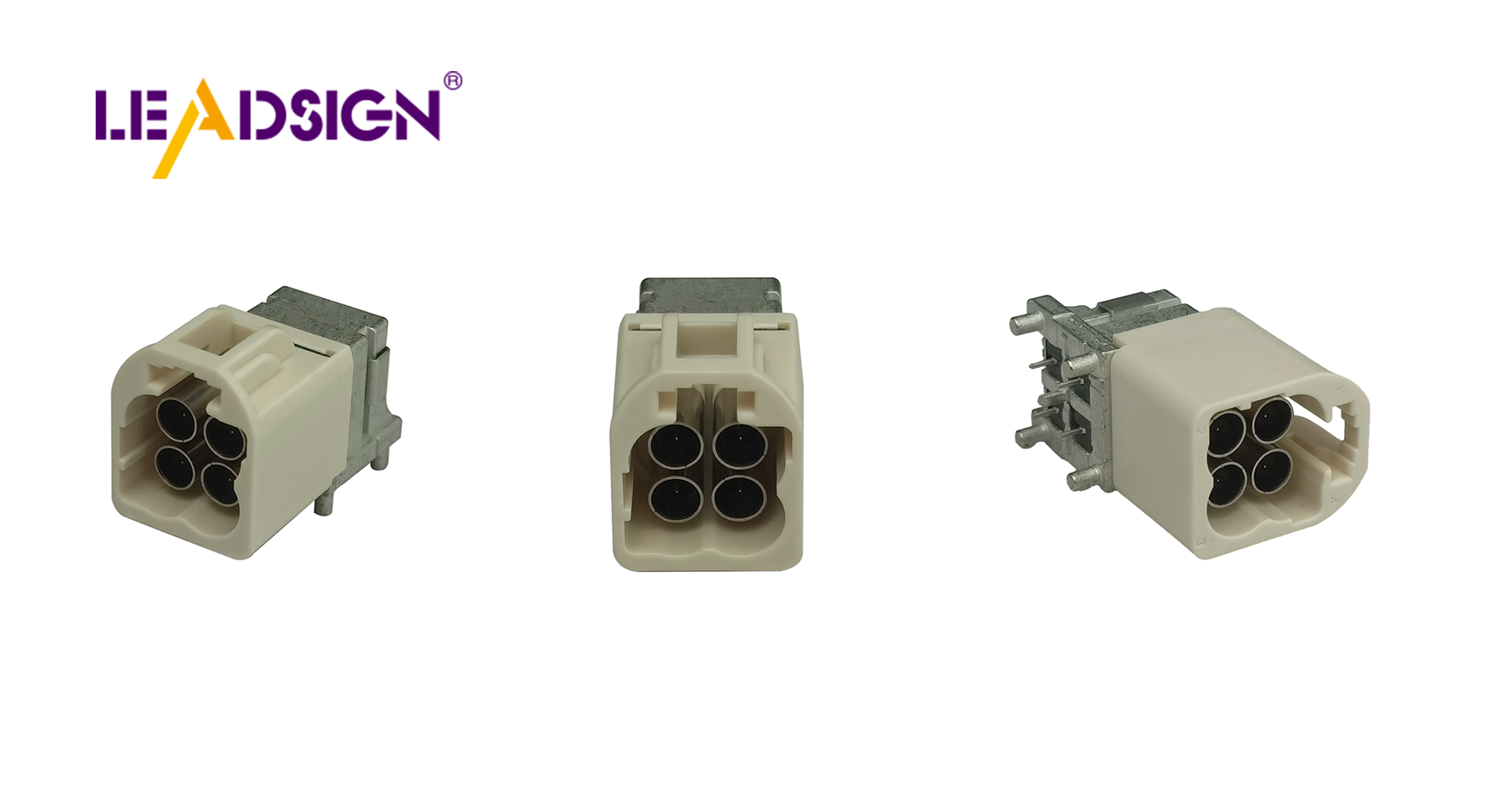

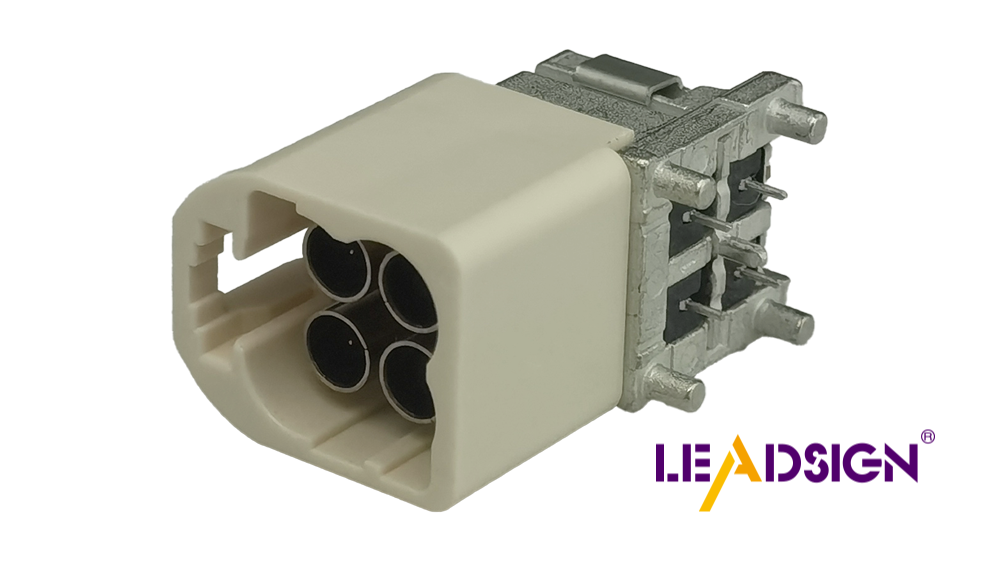

Multi-Pin Connectors

Multi-pin connectors have several pins together, letting you connect many wires at once. These are key in complex systems like engine controls or sound systems where multiple signals need to be sent reliably.

How to Install Connectors

Putting in car wire connectors needs the right tools. You also need to know how to do it well. Here’s a guide on what you need and how to do it.

Tools You Need

You need special tools for putting in car connectors. These help make strong connections.

Crimping Tools

Crimping tools are key for crimp connectors. They squeeze the connector tight on the wire. Pick a tool that fits your wire size and connector type. A good tool makes sure the connection is strong.

Soldering Tools

Soldering tools join wires with solder, making them stick together well. You need a solder iron, solder, and a mat that can take heat. Soldering is best for important connections like engine parts.

Steps to Follow

Here’s how to put in car wire connectors step by step.

Getting the Wire Ready

Take Off Wire Cover: Use a stripper to remove some cover from the wire end so you see metal.

Check the Wire: Look at the bare wire for any damage or rust. If bad, cut and strip again.

Twist Wires Together: Twist strands if they are loose so they fit into the connector easily.

Putting on the Connector

Pick a Connector: Choose one that fits your wire size and job needs like power level.

Put Wire In: Push wire into connector until it stops; no strands should stick out.

Crimp or Solder:

For crimp, use tool to press connector onto wire hard.

For solder, heat joint with iron and add solder until it fills up; let cool without moving it.

Check Connection: Pull gently on wire to see if it's tight and safe.

Cover Connection: Use shrink tube or tape over connection for safety from water or dirt.

By using these steps and tools, you can put in car connectors right. This helps your car work better and stay safe too.

Common Questions and Concerns

Connector Compatibility

Picking the right connector needs knowing what fits well. A good fit makes your car's electrical system work better and safer.

Matching Connectors to Wire Size

When choosing connectors, match them to wire size. Wire size means how thick the wire is. This tells how much electricity it can carry. Using a connector that fits stops overheating and keeps things safe. Always check both wire and connector details to make sure they match. Doing this keeps your car's electrical system strong.

Making Sure It's Weatherproof

Weatherproofing is important for connectors too. Many car connectors face tough weather like rain or heat. Picking weatherproof ones keeps them safe from these things. Look for seals or covers that block water and dirt. This protection helps connectors last longer and work well in any weather.

Fixing Connection Problems

Even with good connectors, problems can happen. Knowing how to fix them saves time and money.

Finding Bad Connectors

Bad connectors cause many issues, like power cuts or failures. To find a bad one, look for damage signs like rust or cracks. You can also use a tester to check if it works right. If it fails, you need a new one.

Fixing Broken Connections

Fixing broken connections is easy with steps to follow. First, take out the bad connector and clean off any dirt or rust. If it's too damaged, get a new one that fits the wire size and conditions needed. When putting on the new one, make sure it's tight and secure. Use shrink wrap or tape to keep it safe from future harm. By doing this, you fix your car's electrical system and stop more problems.

Picking the right connector is key for your car's trustworthiness. The right one can stop heat from rising and avoid problems. When learning about car wiring, think about new things like smart connectors and no-wire connections. These new ideas promise better safety and work. Taking care of connectors keeps your car's electric system working well. Regular checks and quick fixes keep your car running nicely. By knowing more and acting early, you can make your car last longer and work better.

See Also

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System