Understanding Automotive Wiring Connector Types

Automotive electrical connectors are crucial components. They ensure that car parts function efficiently by allowing electricity to flow safely. If these connectors fail, it can lead to car malfunctions or safety hazards. Automotive electrical connectors types are rigorously tested to ensure durability and reliability, adhering to standards such as USCAR-2 and VW80000. Understanding the various types of connectors is essential for selecting the appropriate one for each specific application, enhancing both the safety and performance of vehicles.

Overview of Automotive Electrical Connectors Types

Automotive electrical connectors are very important. They help car parts work together smoothly. These connectors let electronic parts talk to each other, so everything works well. Knowing about different connectors is key for fixing or maintaining cars.

Common Types of Connectors

Blade Connectors: Blade connectors are flat metal pieces that fit into slots. They're used a lot in cars because they're easy and reliable. They make sure connections are strong, perfect for car electrical systems.

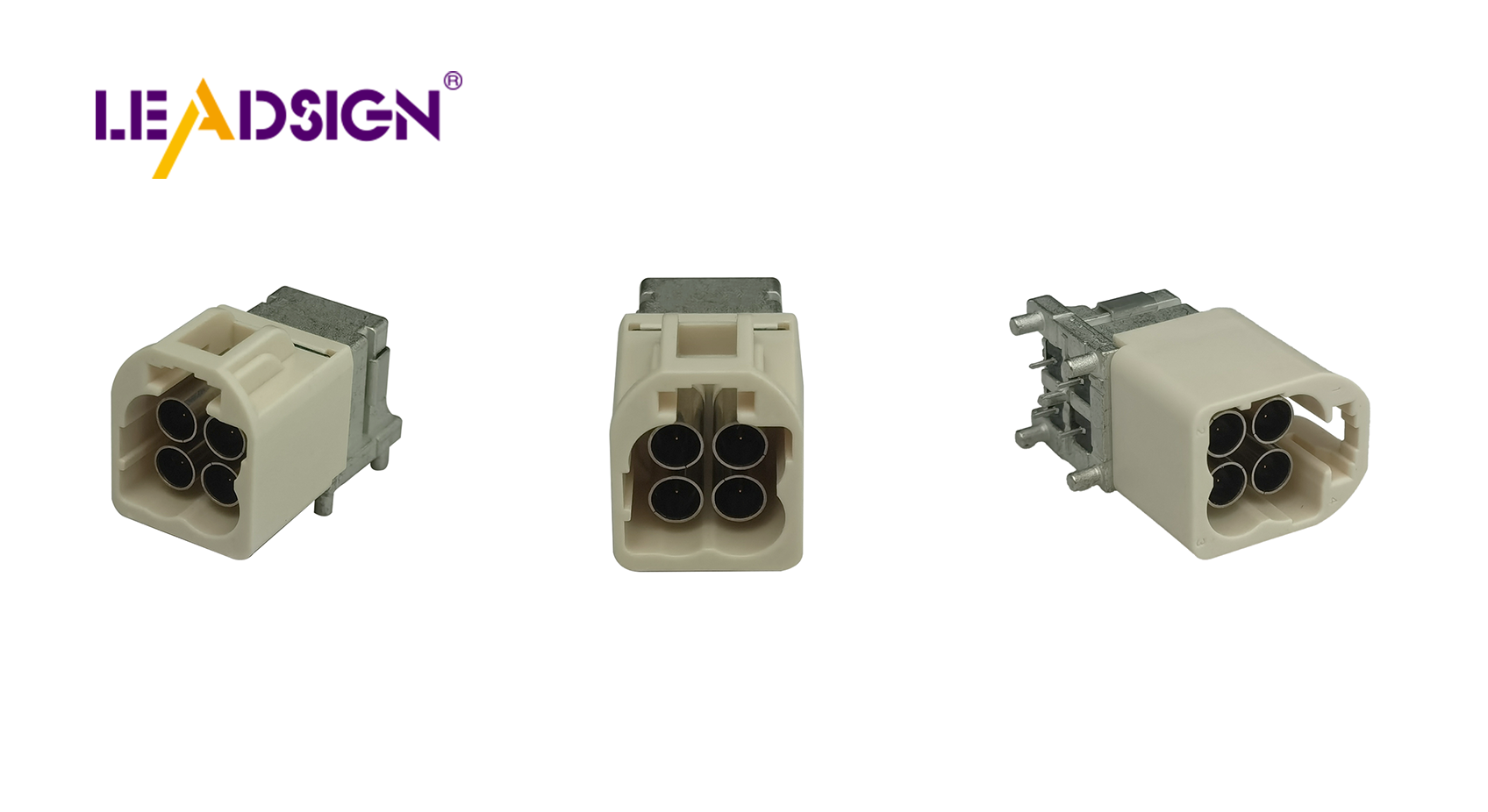

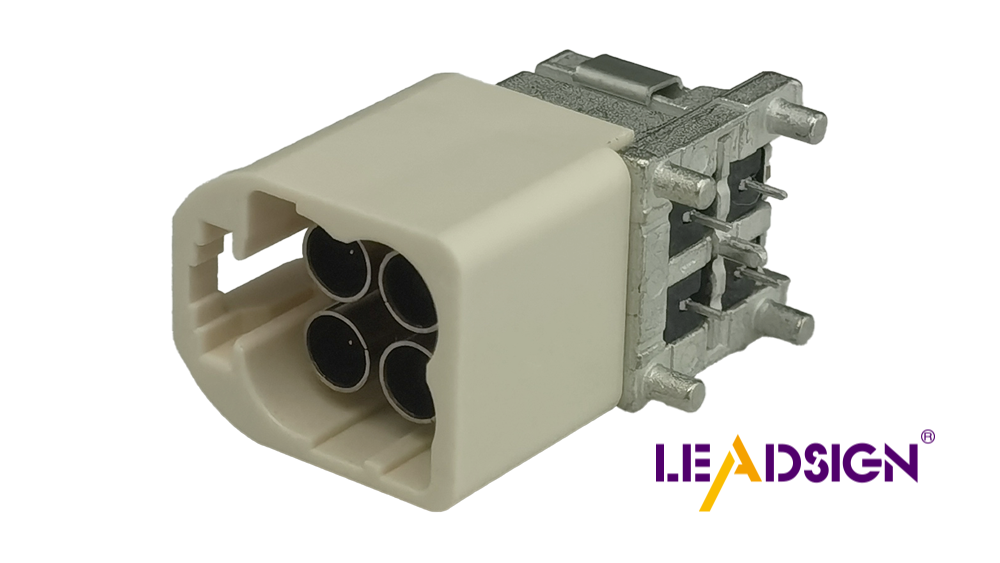

Pin Connectors: Pin connectors have pins that go into sockets. They're used when many connections need to fit in small spaces. Pin connectors are tough and handle lots of electricity well.

Butt Connectors: Butt connectors join two wires end-to-end strongly. They're common in fixing or setting up car wiring. These are great for making wires longer or fixing broken ones.

Materials and Construction

Plastic Connectors: Plastic connectors are light but strong. They're used when cars need to be lighter. Even though they're light, they work well and resist weather changes.

Metal Connectors: Metal connectors are strong and conduct electricity well, good for heavy-duty use where it's hot or stressful on parts.

Applications in Automotive Systems

Engine Systems: In engines, these connectors link sensors and controls, helping the engine run safely and efficiently.

Lighting Systems: In lights, they connect headlights and taillights, ensuring all lights get power to work right.

Audio Systems: For sound systems, they connect speakers and amplifiers, giving great sound throughout the car.

Different automotive electrical connector types meet various needs in cars. By knowing them, you can pick the right one for better performance and reliability.

Main Features and Advantages

Car electrical connectors have many features of car electrical connectors. These make them work well in cars. Knowing these helps pick the right ones for each job, making sure they last long and work best.

Strong and Trustworthy

Being strong and trustworthy is key for car electrical connectors. They need to handle tough conditions to keep working well over time.

Weather Proof

Car connectors face all kinds of weather. They must not let water, heat, or cold stop them from working. Makers use special stuff that stops rust and wearing out. This keeps them good in any weather. New reports show how important it is for connectors to fight weather changes. By doing this, they stay connected well.

Vibration Proof

Cars shake a lot when moving. Car connectors must stay put even with shaking. Studies on toughness say vibration-proof ones break less often. This is important to keep electricity flowing in moving cars. Vibration-proof connectors make sure parts always get power, lowering breakdown chances.

Easy to Put In

Easy installation is a big plus for best automotive wire features. Simple setups save time and cut mistakes when building or fixing things.

Snap-in Connectors

Snap-in ones are quick to set up. You can connect or take them off without tools easily. They're great where you need to fix things often or change them around a lot. Snap-ins hold tight even if there's lots of shaking.

Screw-in Connectors

Screw-ins give a lasting fix but need tools to set up tightly and safely. They're best where you can't afford loose connections because they don't come apart easily, even if moved or stressed.

Troubleshooting and Maintenance

Automotive electrical connectors are key for cars to work well. But, they can have problems over time. Knowing common issues and how to fix them keeps connectors working right.

Common Connector Problems

Corrosion: Corrosion happens a lot in car connectors. Water and weather cause this issue. Rusty connectors can mess up electric flow, causing problems. Checking often finds rust early, stopping more harm.

Loose Connections: Loose connections happen from shaking and use. They can make electric parts stop working sometimes. Keeping connectors tight is important for good connections. Regular checks find loose ones fast.

Good Fixing Tips

Look Closely: First, look at the connectors closely to fix them. Check for wear, rust, or damage signs. Look for color changes or stuff on them that shows rust. Finding these early stops bigger issues.

Use a Multimeter: A multimeter is great for testing connectors exactly. It checks volts, current, and resistance levels. Using it helps check if the connection is good or bad. This tool finds problems eyes might miss.

Case Study: Study of old car connector wear showed fretting wear harms them a lot but they still worked well with care, showing why regular checks matter.

Automotive electrical connectors need regular care to last long and stay strong. By knowing common troubles and using smart fixing ways, you keep car systems working their best.

Choosing the right automotive connector is very important. It helps cars work well and last long. Connectors are key in many places and jobs. Their reliability affects how safe and comfy a car is.

Picking the Right One: Different wire connectors are needed in a car's electrical system. Picking the right ones for weather and use makes them work best.

Keeping Them Good: Regular checks keep connectors working well. Knowing common problems and fixing them smartly keeps car systems strong.

See Also

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System