Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles, ensuring that electrical systems function efficiently. These connectors link various components, facilitating communication and collaboration among them. Without these connectors, cars would frequently encounter electrical issues. Types of automotive electrical connectors include blade, pin, and butt connectors, each serving a specific purpose. Their design and materials enable them to perform reliably in challenging conditions. Understanding these connectors is essential for maintaining the safe and efficient operation of vehicles.

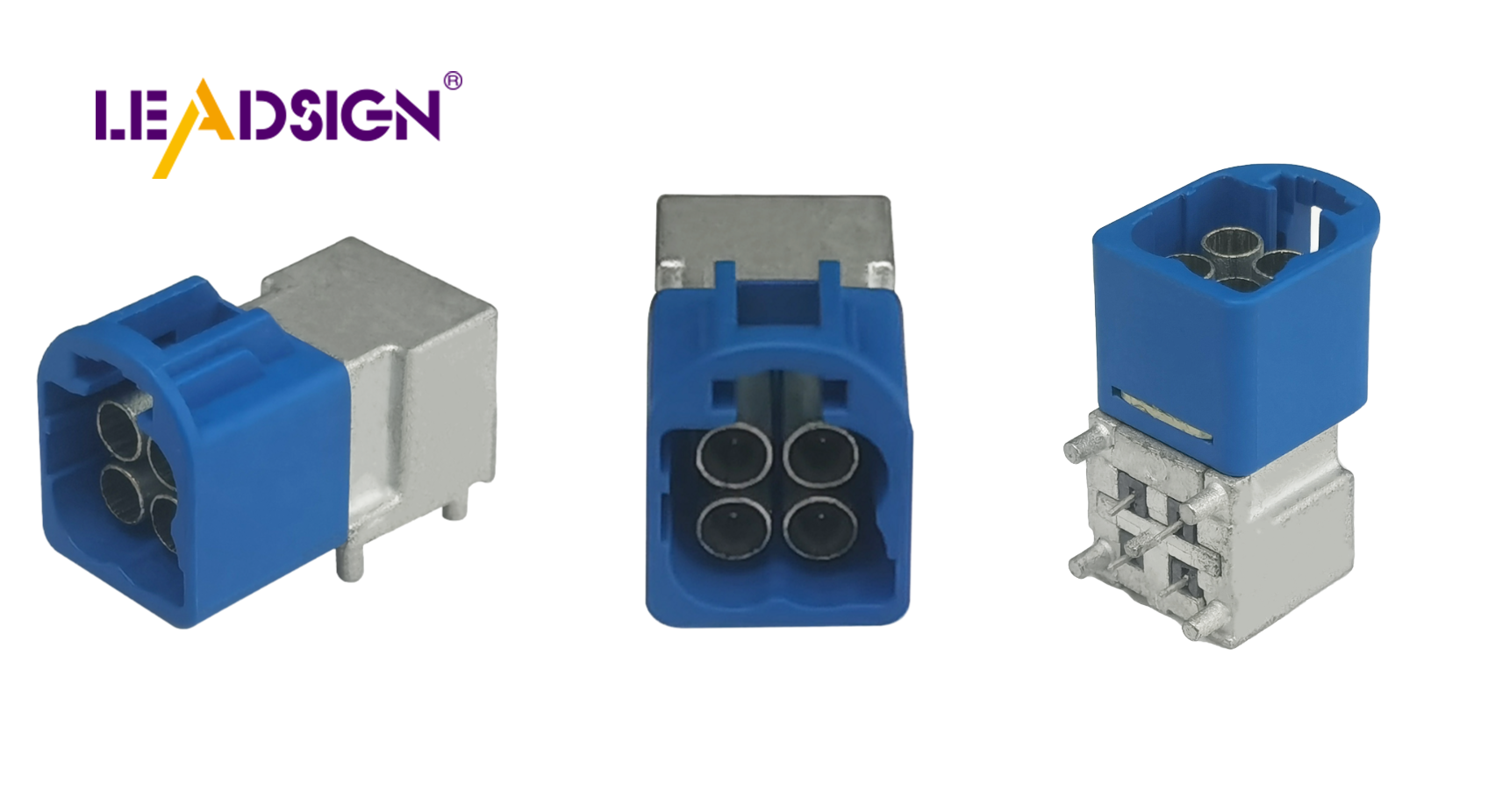

Car Electrical Connectors Types

Car electrical connectors are important for vehicle systems to work well. They come in different shapes and are made for specific jobs. Knowing the types helps pick the right one, making sure things work smoothly. Car electrical connectors are important for vehicle systems to work well.

Blade Connectors

Features and Uses

Blade connectors are simple and easy to use in cars. They can carry a lot of power, so they connect parts that need it. They come in many sizes to fit different wires. Their design makes them quick to connect, which is important when time matters.

Popular Makers

Many companies make good blade connectors that follow rules. TE Connectivity and Molex are famous for their strong connectors. They offer many choices to fit different car systems.

Pin Connectors

Features and Uses

Pin connectors have a metal pin that fits into a matching socket. They're common in computers because they're small and connect well. These connectors handle shaking better than blade ones, so they're good for moving things. They come in single or multi-pin forms for various uses.

Popular Makers

Makers like Amphenol and Delphi create pin connectors for today's car needs. Their products last long and connect securely with different car systems.

Butt Connectors

Features and Uses

Butt connectors join two wires safely together. They're used in car wiring to link wire groups with parts. Different sizes exist for various jobs, making them easy to install quickly.

Popular Makers

Top companies like 3M and Panduit make quality butt connectors that meet standards. Their products handle tough car conditions well, ensuring fast installation.

Features of Car Wiring Connectors

Car wiring connectors are key for cars to work well. They need special features to handle tough conditions. Knowing these helps choose the right ones.

What They're Made Of

What car connectors are made of matters a lot. Makers use copper, brass, and bronze because they carry electricity well and last long. These metals help signals move without losing power.

How Well They Work

Copper connectors let electricity flow easily, which is important for good performance. They also last a long time, handling wear and tear. This is crucial in places with lots of movement.

Standing Up to Weather

Car connectors must resist things like heat and water. Stainless steel and aluminum protect them from damage. This keeps them working even in bad weather.

Design and Fit

The design of car connectors affects how they fit in cars. Good design means they meet different needs.

Different Sizes and Shapes

Connectors come in many sizes and shapes for different wires. Blade ones are easy to connect fast. Pin ones fit tight spaces, perfect for complex systems.

Matching with Wires

Car connectors must match various wire systems well. This makes sure everything works smoothly together, avoiding problems. Makers follow rules so they fit with other parts.

Knowing about car connector features helps keep cars safe and efficient. Picking the right materials and designs ensures they work well in any situation.

How to Install Car Wiring Connectors

Installing car wiring connectors the right way makes them work well and last long. This part tells you how to get ready, what tools you need, and how to do it step by step.

Getting Ready and Tools You Need

Before starting, gather important tools and be safe.

Important Tools

To put in car wiring connectors, you need these tools:

Wire Strippers: These take off the plastic cover on wires without hurting the metal.

Crimping Tool: This tool helps attach connectors tightly to wires.

Screwdrivers: Different sizes help tighten or loosen screws on connectors.

Multimeter: This checks if electricity flows right through connections.

Staying Safe

Safety is very important when working with car wiring connectors. Do these things:

Unplug the Battery: Always unplug the car's battery before working to avoid shocks.

Wear Safety Gear: Use gloves and goggles for protection from electricity and sharp tools.

Work in Fresh Air: Make sure there's fresh air so you don't breathe in bad fumes.

Steps to Install Connectors

Putting in car wiring connectors means joining wires correctly.

Joining Wires

Strip Wire Ends: Use wire strippers to remove about half an inch of cover from wire ends.

Pick Right Connector: Choose a connector that fits your wire size and job.

Put Wire in Connector: Push the wire all the way into the connector hole.

Crimp Connector: Squeeze the connector onto the wire with a crimping tool for a strong hold.

Making Connections Safe

Protect Connection: Wrap with tape or use heat shrink tubing to keep out water and rust.

Check Connection: Use a multimeter to see if electricity flows properly through it.

Reconnect Battery: After checking everything, plug back in the car's battery.

By doing these steps, you make sure car wiring connectors are put in right for good performance. Good techniques like crimping are key for keeping wires strong, as Violin Technologies says. Picking correct ends also helps seal connectors well, as David Cianciolo notes.

Picking the right car wiring connector is very important. It helps the car work well and affects how big or heavy parts are. Choosing correctly can stop problems and keep things connected.

"Choosing and putting in connectors right stops fixes and unhappy buyers."

Using good ways to install them makes them last longer and work better. Think about where you use them for best results. Knowing this helps people keep car systems safe and working well.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors