Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in modern vehicles. They serve as the vital link for power, data, and controls, functioning like the nervous system of a car to ensure smooth operation. Understanding the various types of automotive electrical connectors highlights their significance in maintaining optimal vehicle functionality. These connectors are essential for proper wire connections, making them indispensable components in contemporary automotive systems.

Overview of Automotive Electrical Connectors

Definition and Purpose

What are automotive electrical connectors?

Automotive electrical connectors are key parts in cars. They link different electric systems, making sure power and data move smoothly. These connectors act like bridges between car parts, helping them talk and work well.

Essential role in vehicle functionality

You need these connectors for your car to run smoothly. They make sure things like lights and engine controls work right. Without good connectors, your car might not work well, causing problems or breakdowns.

Basic Features

Material composition and durability

Car connectors must handle tough conditions. Makers use materials that resist heat, rust, and wear. For example, the Triton Series Automotive Connector has strong seals and resists shaking, perfect for electric cars. These materials keep connectors strong over time.

Design and operational functionality

Car connector designs focus on being efficient and reliable. Small designs like the HR41 Series Automotive Connector help fast data transfer for smart systems like ADAS. These connectors are built strong to meet car needs. As tech grows, connectors will change too, getting smaller to fit future trends.

Car connector designs focus on being efficient and reliable. Small designs like the HR41 Series Automotive Connector help fast data transfer for smart systems like ADAS. These connectors are built strong to meet car needs. As tech grows, connectors will change too, getting smaller to fit future trends.

Types of Car Electrical Connectors

Knowing different car connector types helps keep your car's electric system working. Each type has a special job and offers its own benefits.

Blade Connectors

What They Are and How They're Used

Blade connectors look like flat blades. You can slide them into slots easily. They hold wires tight and are great for connecting to circuit boards. Their design lets you unplug them fast, which is handy for fixing things.

Where You Find Them in Cars

In cars, blade connectors are often in fuse boxes and relay panels. They also connect sensors and switches. They handle medium power well, so they're used a lot in cars.

Pin Connectors

What They Are and How They're Used

Pin connectors have pins that fit into matching holes. They're mainly for connecting wires to each other. They're strong and stay connected even if the car shakes.

Where You Find Them in Cars

You usually see pin connectors under the hood or dashboard. They link wire bundles together, important for engine controls where they must work well.

Butt Connectors

What They Are and How They're Used

Butt connectors are tube-shaped parts joining wires together. They keep connections safe from outside stuff getting in. Use them to make wires longer or fix breaks.

Where You Find Them in Cars

In cars, butt connectors are used for lights and sound systems. They're good when you need to join wires or fix things where soldering is hard.

Special Connectors

What They Are and How They're Used

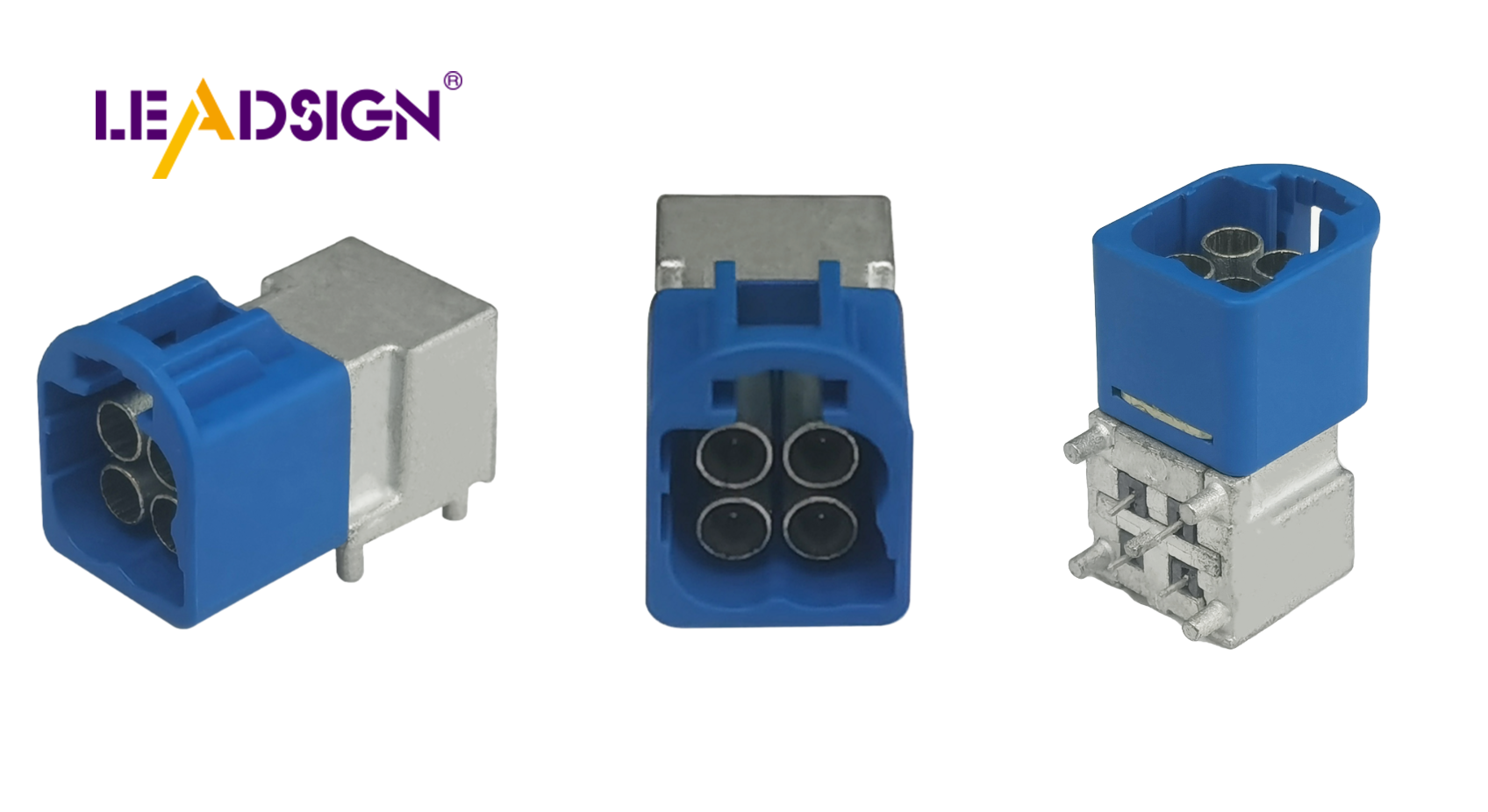

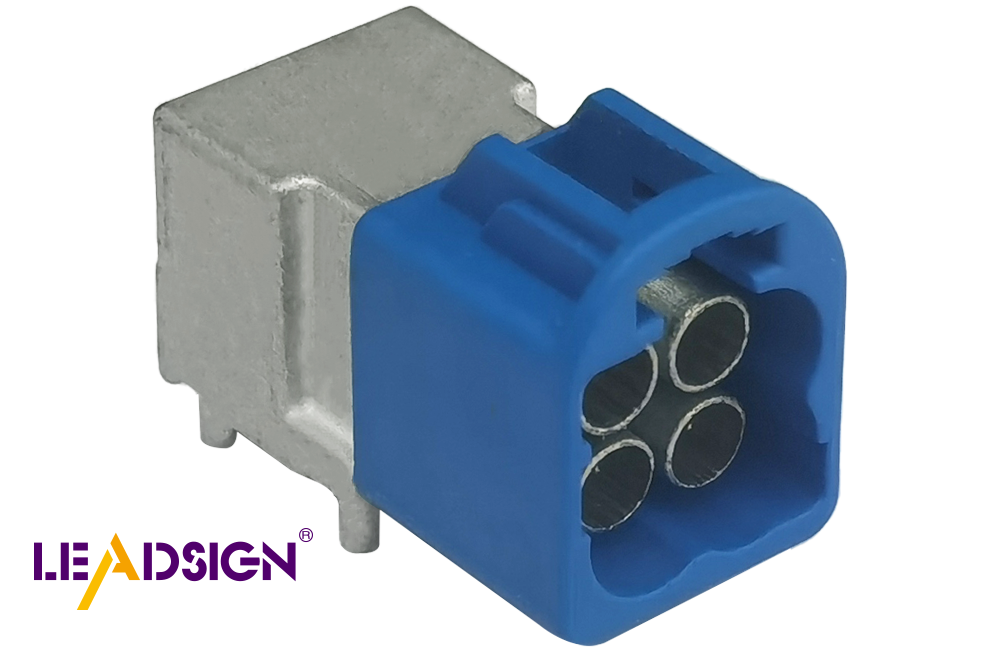

Special connectors are different because of their special shapes and jobs. They are used in places where regular connectors don't work well. These connectors often have better seals to keep out water and dirt. This makes them perfect for tough spots in cars.

Also, special connectors have strong locks that keep them from coming apart. Even if the car shakes, they stay connected. They are made easy to use, so you can put them on or take them off quickly without problems.

Where You Find Them in Cars

In cars, special connectors are very important in many systems. You might see them in fast cars or smart driving systems like ADAS. They can handle heat and shaking, so they are needed there.

Special connectors also help with car radios and screens by moving power and data smoothly. In electric cars, they help manage batteries by sharing power well between parts.

Knowing about special connectors helps you see why they matter for keeping car systems working right. These connectors make sure your car runs smoothly with other connector types.

Installation Techniques

Installing automotive electrical connectors right makes them last longer. This part shows the tools and steps needed.

Tools Needed

Important tools for installing

To put in these connectors, you need:

Wire Strippers: They take off wire covers without harming the wires.

Crimping Tool: It attaches connectors to wires tightly.

Screwdrivers: Use them to loosen or tighten screws on parts.

Multimeter: Checks if connections have the right voltage.

Heat Gun: Helps shrink tubing for extra cover and safety.

Safety tips

Being safe is key with electric work. Do this:

Unplug the battery before starting to avoid shocks.

Wear goggles to keep eyes safe from sparks or bits.

Use tools with covers to stop electric shocks.

Work where air moves well to not breathe bad fumes.

Step-by-Step Guide

Getting wires ready

Cut Wire: Trim wire with cutters to needed length.

Strip Insulation: Take off about half an inch of cover using strippers.

Twist Strands: Twist bare wire ends together for a snug fit.

Joining wires

Pick Connector: Choose the right type like Triton Series Connectors for tough spots.

Put Wire In: Push bare wire into connector till it stops.

Crimp Connector: Squeeze connector onto wire tight with crimper.

Making connection secure

Check Connection: Ensure wire is tight and no strands are loose.

Use Heat-Shrink Tubing: Slide tubing over joint, heat it for more safety cover.

Test Connection: Check with multimeter that flow is good and steady.

By doing these steps, your car's electrical system will work better and last longer with proper connector installation.

Common Problems and Fixes

Fixing Connector Problems

Finding usual issues

You might face problems with car connectors. Loose ones can make lights flicker. Water can cause rust, making them work poorly. Worn-out wires or bad installs can break them. Spotting these early stops bigger troubles.

Fixes and ways to stop them

Check connectors often for rust or wear. Clean rusty parts with cleaner and tighten connections. Use special grease to keep water out. Follow instructions when putting in new ones to avoid harm. Regular checks and good installs lower connector problems a lot.

Q&A Part

Common questions

How do I spot a bad connector?

Flickering lights or broken parts show a bad connector.

Should I fix or change a broken connector?

Small fixes are okay, but changing it is safer.

What tools do I need for fixing connectors?

You need wire cutters, crimpers, and a tester tool.

Expert tips and help

Experts say use good car connectors only. They stress checking them often for best results. If problems stay, ask an expert for advice and help. Staying alert helps your car's electric system run well.

Choosing the correct connector keeps your car's electrical system strong. Each connector has a special job, so knowing what they do helps you choose wisely. Picking connectors that fit your car's needs boosts how well it works and lasts.

"The right connector choice is key for a reliable car electrical system."

To keep systems strong, check them often and install correctly. Be active in looking at and changing connectors when needed. This way, your car runs well and safely, giving you peace of mind on every trip.

See Also

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System