Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in car systems. They facilitate communication between components, enhancing the performance and safety of vehicles. As automotive technology advances towards electrification and connectivity, the demand for improved wiring solutions grows. These connectors play a vital role in supporting features like self-driving capabilities and 5G connectivity. There is a variety of automotive electrical connectors available, each serving a specific function. They ensure efficient data transmission and reliable power delivery. The selection of the appropriate connectors significantly impacts the performance, long-term cost, and durability of modern vehicles.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They link circuits, allowing parts to talk to each other. These connectors come in many types, each made for certain jobs in cars. They give a strong link, keeping the car's electrical system working well.

Importance in Automotive Systems

Automotive electrical connectors types are important for how cars work and stay safe. They help send power and data, needed for new car tech to work right. As cars get better, we need stronger connectors more than ever. These must handle tough conditions like heat changes and wetness to last long.

Basic Components of Connectors

Knowing connector parts helps pick the right one for a job. Each part is important for how well the connector works.

Terminals

Terminals are the main part of any connector. They connect wires so electricity can flow. In cars, terminals need to be strong and not rust. Crimp connectors use tools to hold wires tight, making sure they stay connected even with shaking or other stresses.

Housings

Housings cover terminals, giving them safety and support. They keep terminals lined up so they don't come apart by accident. Chassis or panel connectors fix onto equipment frames or panels, letting people safely attach cables to machines that don't move.

Seals

Seals guard inside parts from outside stuff like water or dirt. This stops rust or electric problems from happening. Strong OEM automotive wire connectors show why using good materials is key in tough car places to avoid rust or big problems.

Types of Automotive Electrical Connectors

Blade Connectors

Features and Uses

Blade connectors are common in cars. They are easy to use. A flat metal piece fits into a slot. This makes them quick to connect and take apart. They are great for lights and speakers because they are simple.

Good and Bad Points

Blade connectors are easy to use. They help with fast fixes or swaps. But, they might not protect well from weather. This can cause problems over time.

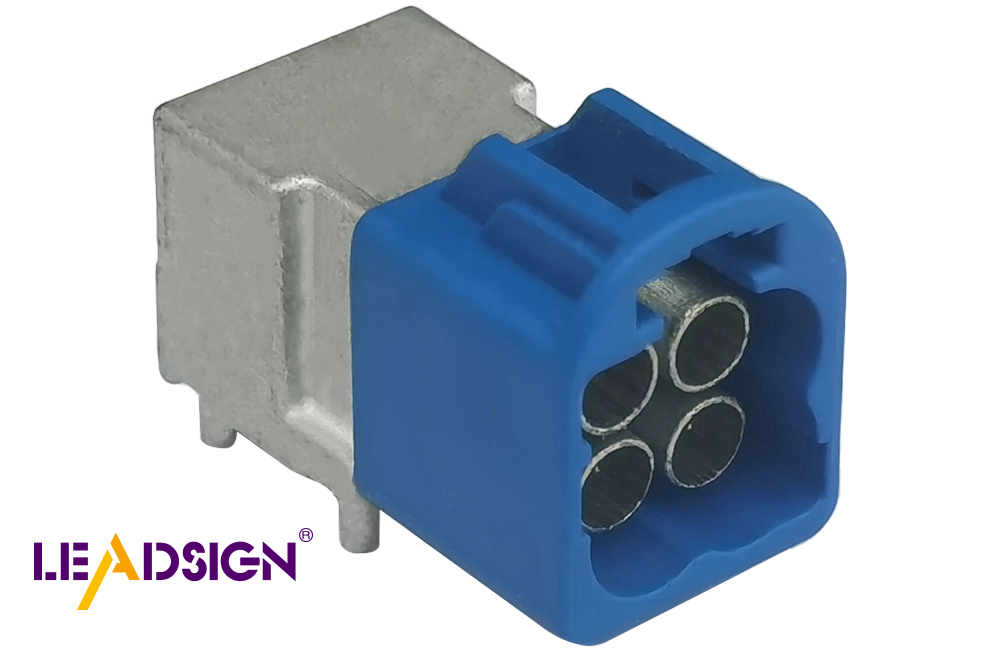

Pin Connectors

Features and Uses

Pin connectors have pins that fit into sockets. They protect better than blade connectors. These are used in engines and sensors where strong connections matter.

Good and Bad Points

Pin connectors keep out dirt and water well. They stay connected even if bumped. But, they can be hard to put together. You might need special tools, which takes more time.

Butt Connectors

Features and Uses

Butt connectors join two wires firmly together. They look like metal tubes holding wires end-to-end. They're good for lasting connections in wire bundles or power systems.

Good and Bad Points

Butt connectors hold wires tight so electricity flows well. Once set up, they don't come apart easily, which is good for safety but bad if you need changes later.

Ring and Spade Connectors

Features and Uses

Ring and spade connectors are special. They have a metal ring or spade end. This end fits onto a bolt or screw tightly. It keeps them from shaking loose. They work well where things move a lot.

In cars, ring connectors help with grounding. They connect to the car's frame, making sure everything works right. Spade connectors are easy to take off and put on. They're good for parts you check often.

Good and Bad Points

Ring and spade connectors stay put once attached. This is great in places that shake, like engines.

But, they can be tricky to install. Blade or pin connectors are faster to use. Also, removing ring connectors needs taking off the whole bolt or screw, which can be a hassle sometimes.

Picking the Right Connector

Choosing the right car connectors is very important. It helps cars work well and stay safe. The correct choice stops electrical problems and makes car parts last longer. Here are things to think about when picking connectors:

Things to Think About

Electrical Needs

Each car part needs certain electricity. Connectors must fit these needs for good power flow. For example, fast data connectors like HSD are great for quick data moves, like USBs or music systems. Knowing how much power is needed stops overheating.

Weather Conditions

Cars face tough weather like heat, wetness, and shaking. Connectors need to handle this to work well. Sealed connectors keep water out, so they’re good in wet places. Strong seals and tough materials make them last long in hard spots.

Fit with Car Parts

Connectors must match car parts perfectly. They should fit the car’s look and job well. For instance, ring connectors hold tight on screws; spade ones are easy to attach or remove. Good fit stops install troubles.

Mistakes to Avoid

Wrong Size

Picking the wrong size can cause bad links and fails. Match connector size with wire size right. Wrong sizes can lead to loose links causing shorts or problems.

Forgetting Weather Effects

Ignoring weather can hurt connector work. Using open connectors in wet areas causes rust and fails. Think about where it works and pick ones that handle those spots well.

By thinking of these points and avoiding mistakes, you can choose the best car connectors for your vehicle's needs.

Choosing the right car wiring connector is very important. It helps cars work well and stay safe. Connectors affect how good and reliable the car's electric links are. Picking connectors for their job is key to working best.

Think about power needs, weather, and fit with car parts. Use connectors that handle heat and wetness for lasting use. Knowing these things helps people choose better. This makes cars work better and last longer.

See Also

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors