Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial for vehicles, ensuring the car's electronics function efficiently. These connectors consist of four main components: contacts, shell, insulator, and additional features. Each component enhances the connector's performance and durability. OEM connectors are designed to fit specific car devices, ensuring safe and effective operation. Understanding the various types of automotive electrical connectors aids in selecting the appropriate one, guaranteeing the car operates smoothly and reliably.

Understanding different car wire connectors is important for cars to work well. Each connector type has its own job and special features.

Blade connectors, also called spade connectors, are common in cars. They have a flat metal piece that fits into a slot. This makes them easy to connect and disconnect quickly. Blade connectors are used where you need to unplug things often, like fuse boxes.

Blade connectors have good points. They stay connected even when the car shakes, which is great for cars. They are simple to use without special tools. But they might not be good for high power because they don't touch much metal. Over time, they can get loose if not checked.

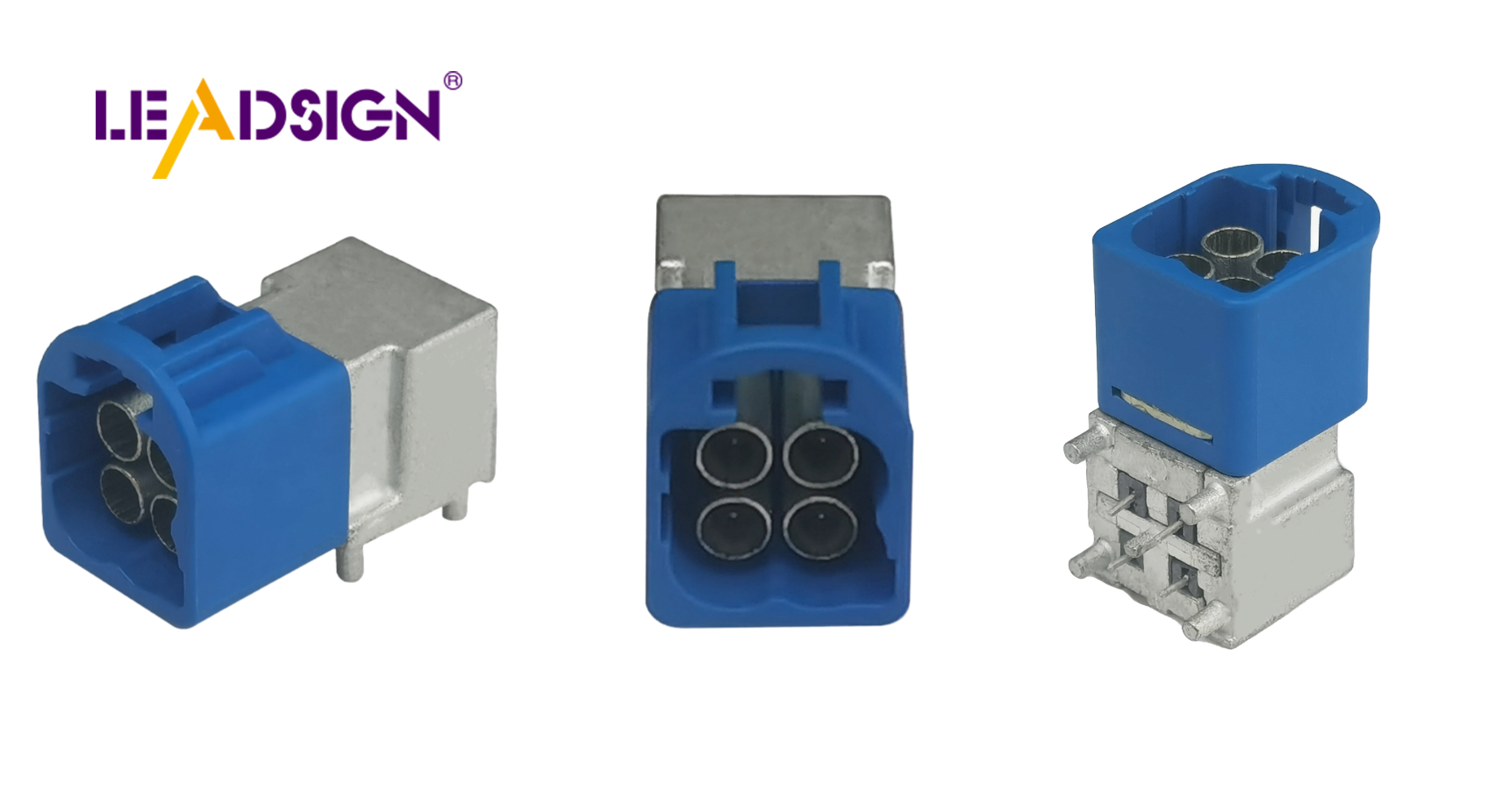

Pin connectors have pins that go into sockets. They're used when many wires need connecting in small spaces. Pin connectors come in different shapes like circles or rectangles.

Pin connectors are very reliable and handle lots of power well. They make strong connections, which is key in cars. But they're harder to put together than blade ones because they need exact fitting. If not sealed right, pin connectors can rust.

Butt connectors join two wires end-to-end and are used for fixing car wires easily without soldering.

Butt connectors are easy to use and make quick wire fixes possible. They conduct electricity well but might loosen with lots of shaking unless crimped properly.

Things to Think About When Picking Connectors

When picking car wire connectors, you must think about a few important things. These help you choose the right connector for your car.

Power Needs

Current and Voltage Levels

Car wire connectors need to handle certain power levels. Each type can take only so much electricity. For example, high-power uses need connectors that can carry more power. Picking the right ones stops them from getting too hot and keeps everything safe.

Environment Factors

Where car wire connectors are used affects how they work. In cars, they face heat, wetness, and shaking. OEM automotive wire connectors are made to handle these tough conditions. They use strong stuff and special ways to stop rust and breaks. This makes sure they stay working well even in hard places.

Build Needs

Strength and Materials

How long car wire connectors last depends on what they're made of. Good materials make them last longer and not wear out fast. Chassis or panel connections hold tight by sticking well to the car's body. This is important for keeping good electric links in cars.

Size and Fit

Size and fit matter when picking car wire connectors. They must match the car's wires and parts perfectly. OEM connectors fit certain car parts, making fixes easy without problems. Using the right size stops issues and makes sure new parts work with old ones.

Common Problems and Fixes

Car wire connectors are important for car electronics to work well. But, they can have problems too. Knowing these issues and how to fix them keeps the car's wires working right.

Bad Connections

Bad connections in car wires cause many problems. These range from small electric troubles to big system failures. Here’s why they happen:

Loose Fittings: Car shaking makes connectors loose over time. This causes weak links. Check and tighten them often to stop this.

Wrong Installation: If not put on right, connectors don't touch wires fully. Use the right tools and follow rules for good installation.

Wear and Tear: Using them a lot or bad weather wears out connectors. Replace old ones with strong OEM types for better use.

"Car connectors must meet standards like USCAR-20 for lasting contact."

Causes and Fixes

Cause: Loose links from shaking.

Fix: Check and tighten all connectors regularly.

Cause: Wrong setup.

Fix: Follow correct steps and use proper tools.

Cause: Wear from weather.

Fix: Swap with tough OEM parts for long life.

Rust and Damage

Rust is a common problem that hurts car connectors' work. It happens when water or air makes metal rust, causing bad electric flow.

Water Exposure: Water gets into connectors, making rust form. Use sealed ones to keep water out.

Chemical Exposure: Road salt speeds up rusting. Clean connectors often to lower this risk.

Material Quality: Bad materials rust easier. Buy good ones for better protection against weather.

"OEM parts help keep power flowing well between car parts, lowering rust risks."

Prevention and Care

Prevention: Use sealed parts to block water.

Care: Clean them often to clear dirt or chemicals away.

Prevention: Pick good materials for less rust.

Care: Look at parts often; change rusty ones quickly.

By fixing these usual problems, car wire links stay strong, helping the car's systems run their best.

Choosing the right car wire connector is very important. Picking connectors with well-made terminals helps electricity flow well. OEM connectors fit certain car parts, making them work reliably. When looking at connections, size and power are key. Knowing these things helps people choose better, making their car's wires last longer and work better. Choosing the right connector type keeps the car running well and safe in different driving situations.

See Also

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors