Understanding Automotive Wiring Connector Types

Understanding automotive electrical connectors types is crucial for repairing vehicles. These connectors play a vital role in a car's performance by linking various electrical components, such as headlights and safety systems. As automotive technology evolves, so do these connectors. Innovations in materials and manufacturing techniques have led to the development of smaller, more robust connectors capable of handling increased electrical loads. Additionally, electric and self-driving cars require advanced connectors, highlighting their significance in modern vehicles.

Basics of Automotive Electrical Connectors

Role in Vehicle Systems

Automotive electrical connectors are very important for cars. They help connect and send signals between different parts. These connectors join things like sensors, lights, and control units so they can talk to each other. A good connection makes sure signals move smoothly, keeping the car working well.

These connectors also share power from the battery to other parts. This sharing helps run things like starting the car, lights, and music systems. If power isn't shared right, these parts might stop working and affect the car.

Key Features

Car connectors have special features that make them work better. Durability and weather resistance are very important traits. They can handle tough conditions like hot or wet weather. Materials such as nylon and thermoplastic elastomers make them strong for a long time.

Being compatible with car systems is also key. Connectors need to fit the car's electric system perfectly. This fitting makes sure they stay in place and work right. Picking the correct connector stops problems like loose fits or signal issues that could break systems.

Types of Car Electrical Connectors

Knowing car electrical connectors is important for fixing or designing cars. These connectors help car systems work well. Let's look at some common types and how they are used.

Blade Connectors

Blade connectors, also called spade connectors, are very common in cars.

How They Work and Why They're Good

Blade connectors join wires easily and safely. They have a flat metal piece that fits into a slot. This makes them quick to connect and disconnect, which is useful when you need to unplug often. They carry electricity well and don't shake loose, which is important in cars.

Where They're Used in Cars

In cars, blade connectors are used in wire bundles, fuse boxes, and relay spots. They connect lights, music players, and other electric parts. Their ease of use makes them popular with makers and fixers.

Pin Connectors

Pin connectors are another common type of car electrical connector. They have pins that fit into matching holes.

How They Work and Why They're Good

Pin connectors can handle many connections at once. They're used where lots of signals need sending together. Their design keeps them tightly connected so they don’t come apart by accident. They also keep out water and dust.

Where They're Used in Cars

Pin connectors are found in engine controls, sensor links, and dashboard wires. They help important systems talk to each other well for safety and performance.

Butt Connectors

Butt connectors are simple but good car electrical connectors. They join two wire ends together.

How They Work and Why They're Good

Butt connectors make strong permanent joins that stay safe from weather. They're easy to put on with few tools needed, great for fast fixes or setups.

Where They're Used in Cars

In cars, butt connectors fix or change wires often used for lights or sound systems where a lasting connection is needed.

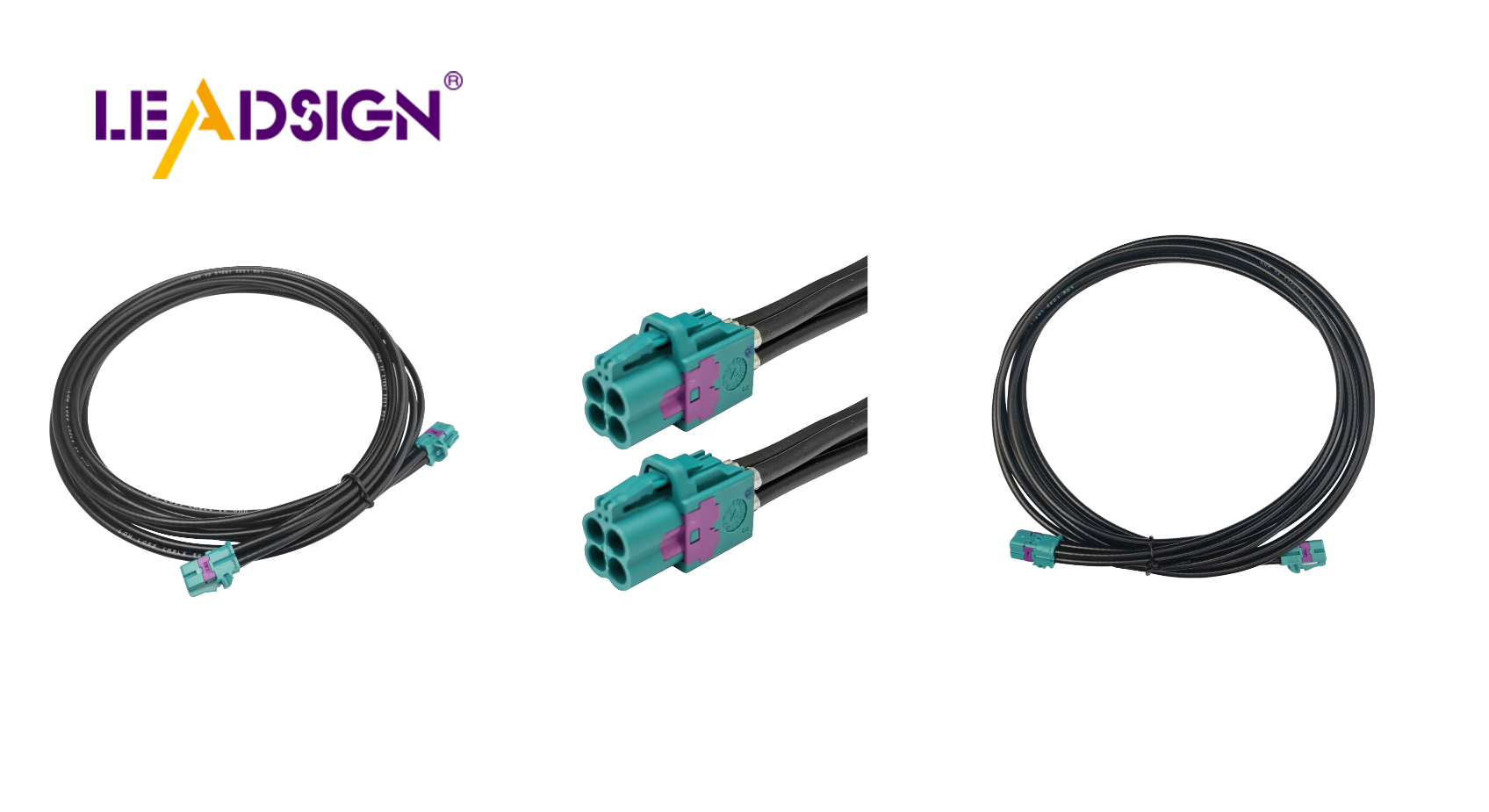

FAKRA Connectors

FAKRA connectors are special among car connectors. They are key in new cars with tech like self-driving and entertainment systems.

Uses and Advantages

FAKRA connectors are important in cars. They handle high signals, perfect for systems needing exact data. Car experts stress their role in making sure parts talk well. FAKRA connectors work with GPS, satellite radio, and driver help systems. They send data fast without problems, which is crucial for these technologies to work smoothly.

FAKRA connectors are strong and small. They can face tough conditions like heat and wetness common in cars. This strength means they last long and avoid signal issues or breaking. Plus, their design makes them fit easily into different car parts while saving space.

Common Vehicle Uses

In car connector types, FAKRA connectors are used a lot in vehicles. They're key for infotainment systems, giving clear sound and video to make driving better. These connectors also help navigation by sending accurate GPS data quickly.

FAKRA connectors are vital for safety and driver help systems where good communication is needed. They link cameras, sensors, and radar for features like lane warnings and cruise control that adjusts speed. By keeping connections steady, FAKRA connectors boost the safety and efficiency of today's cars.

Installation Techniques

Knowing how to install automotive electrical connectors is important. It helps keep connections strong in cars. Good installation makes cars work better and stops problems like loose wires. Let's look at three ways: crimping, soldering, and heat shrinking.

Crimping

Crimping is a common way to join wires with connectors. It means squeezing a connector onto a wire for a tight hold.

Tools and Methods

To crimp, you need special tools for each connector type. These tools press the connector tightly on the wire. First, strip the wire, put it in the connector, then use the tool to crimp it.

Advantages and Disadvantages

Crimping has good points:

Speed: It's fast and easy.

Reliability: Crimps are strong.

No Heat Required: No heat needed, so parts stay safe.

But there are downsides:

Tool Dependency: Needs different tools for each type.

Skill Requirement: Must do it right or it's weak.

Soldering

Soldering joins wires with melted metal called solder.

Tools and Methods

You need a solder iron, solder, and flux. Heat the iron, add flux to wire and connector, then melt solder to stick them together well.

Advantages and Disadvantages

Soldering is good because:

Strong Connection: Makes a solid bond.

Conductivity: Great for electricity flow.

But it also has issues:

Time-Consuming: Takes longer than crimping.

Heat Risk: Too much heat can hurt parts.

Heat Shrinking

Heat shrinking protects connections by covering them with tubing that shrinks when heated.

Tools and Methods

Use shrink tubing and a heat gun. After connecting wires, slide tubing over them. Heat it so it fits snugly around everything.

Advantages and Disadvantages

Heat shrinking helps by:

Protection: Keeps out water and dirt.

Neat Appearance: Looks tidy when done.

Yet there are challenges:

Additional Step: Extra step after connecting.

Heat Application: Be careful not to overheat parts.

Common Problems and Maintenance Tips

Common Issues

Rust and Damage

Car connectors can rust and wear out. This happens because they face tough conditions. Water, salt, and dirt cause rust. Rust stops electricity from flowing well. Over time, this makes connectors weak or broken. Shaking and pressure also wear them out.

Loose Connections

Loose connections are a big problem in car wiring. They happen when connectors aren't tight enough. This causes lights to flicker or sensors to fail. Sometimes, whole systems stop working. Loose connections come from bad installation or natural loosening over time.

Preventive Maintenance

Regular Checkups and Cleaning

Checking and cleaning car connectors often helps avoid problems. Workers should look for rust or damage regularly. Cleaning with the right stuff removes dirt and water, stopping rust. Clean connectors keep electricity flowing well.

Good Storage and Care

Storing and handling connectors right is important too. Keep them dry and clean when not used to avoid moisture damage. Don’t bend or twist them too much during use as it can break them. Use proper tools like crimpers for safe connections.

Picking the right car wiring connector is very important. It helps cars work well and stay reliable. Knowing electrical connectors helps fix cars better. This blog talked about different connector types, how to install them, and tips for taking care of them. Checking and caring for connectors often stops problems, say car experts. By choosing good connectors and keeping them in shape, people can make their cars last longer and run better.

See Also

Understanding HSD Connectors Essential for Automotive Applications

Why Fakra Connectors Are Crucial for Today's Vehicles

A Comprehensive Overview of Ford's Fakra Connectors