Understanding Automotive Wiring Connector Types

Automotive electrical connectors are crucial in modern vehicles, facilitating the connection of various electrical components to ensure optimal performance and safety. These connectors must withstand harsh conditions such as vibration, corrosion, and extreme temperatures. Engineers meticulously select materials to ensure durability and reliability. There are various automotive electrical connectors types, including Deutsch and Weatherpak, each designed to meet specific requirements. Their design allows for easy assembly and maintenance, making them indispensable in automotive manufacturing.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are key parts in car systems. They link circuits so electricity can move between vehicle parts. These connectors make sure power and signals go where needed without stopping. By keeping connections secure, they protect the car's electrical system.

Why are they essential in automotive systems?

Car systems need wiring connectors for many reasons:

Reliability: Connectors keep electrical links steady, which is vital for car parts to work right.

Safety: They stop loose links, cutting down on electrical problems that might cause accidents or issues.

Efficiency: Connectors make putting together and fixing cars easier, saving time and money.

General Characteristics

Material composition

The materials used in wiring connectors are important for how they work. Engineers pick materials with good conductivity and corrosion resistance. Common choices include:

Copper: Known for great conductivity and being bendable.

Brass: Has strong mechanics and resists rust.

Aluminum: Light, cheap, often used in large amounts.

These materials help connectors handle tough car conditions.

Durability and resistance features

Car wiring connectors must survive tough situations like shaking, heat, and wetness. To do this, makers add durability features:

Vibration Resistance: Connectors stay tight even when moving a lot.

Temperature Tolerance: They work well from very cold to very hot temperatures.

Corrosion Resistance: Special coatings stop rust over time.

These traits make car wiring connectors strong and lasting, ensuring the car's electric system runs smoothly.

Automotive electrical connectors have different types for different uses. Knowing these helps pick the right one for cars.

By Connection Type

Crimp connectors

Crimp connectors are common in cars because they are easy and reliable. They join wires by squeezing a metal piece around them, making a strong link. This way, no soldering is needed, so it’s fast to set up. Crimp connectors also handle shaking well, which is important in cars.

Solder connectors

Solder connectors make a lasting link using solder to join wires. They give a strong electric connection and are used when reliability is key. Installing solder connectors takes more skill and time than crimp ones but they conduct electricity better and last in tough conditions.

By Application

Power connectors

Power connectors manage high currents like battery links. They must handle heat and stay secure to stop power loss. Copper and brass are often used because they conduct well and last long.

Signal connectors

Signal connectors send low-voltage signals between parts like sensors. They need exact links for correct data sending. Signal connectors on them stops rust and helps conduction, perfect for delicate electronics.

By Design

Male and female connectors

Male and female connectors fit together with pins going into sockets. This makes sure connections don’t come apart by accident. They’re used in many car parts from lights to engines.

Multi-pin connectors

Multi-pin connectors let many wires connect at once, making wiring simpler. These are key in new cars where many systems talk to each other easily. They often have waterproof seals and locks for strength.

Standards and Specifications

ISO Rules

What are ISO rules?

ISO makes global rules for car wiring connectors. These rules make sure connectors are safe and good quality. For example, ISO rules like ISO 6722 talks about car cables needing to handle heat well. ISO 8092 is about connectors in cars being strong and lasting long.

Why follow these rules?

Following ISO rules means car connectors work well in tough spots. Makers who follow these rules make connectors that can take on heat, shaking, and wetness. This makes cars safer and lets parts fit together across different brands.

Industry Rules

Common industry rules

Besides ISO, the car world has other rules to keep things good. SAE (Society of Automotive Engineers) has rules like SAE J1128 for low-power cables. These look at things like how thick the cover is or what metal is used inside. Following these helps connectors work right in many car uses.

Special maker guides

Car makers often have their own special guides for their needs. These might say what materials to use or how a connector should lock in place. By following these special guides, engineers make sure parts fit into cars perfectly, making them work better.

Picking the Right Connector

Choosing the right car wiring connector is very important. It helps make sure a car's electrical system works well. This part will help you know what to think about and mistakes to avoid when picking connectors.

Things to Think About

Electrical needs

Current Capacity: Know how much current the connector must carry. Pick connectors that can handle this without getting too hot.

Voltage Rating: Make sure the connector's voltage rating is as high or higher than needed. This stops electrical problems.

Contact Resistance: Choose connectors with low contact resistance for good power flow. This saves energy and keeps things cool.

Environment conditions

Temperature Range: Pick connectors that work in the car's temperature range, both hot and cold.

Vibration Resistance: Get connectors that can handle shaking in cars, so they stay connected.

Moisture and Corrosion Resistance: Use connectors with coatings or seals to keep out water and rust, making them last longer.

Mistakes Not to Make

Missing compatibility checks

Connector Type: Make sure the connector fits with the system design, or it might not work right.

Material Compatibility: Check if connector materials match wire materials, stopping bad reactions.

Forgetting quality rules

Industry Standards: Follow rules like ISO and SAE for safe and good performance.

Manufacturer Guidelines: Listen to what makers say for best results and fitting parts together.

By thinking about these points and avoiding mistakes, you can pick connectors that make car systems better and more reliable. Good material choice and design help solve problems in cars, keeping them running well.

Knowing about automotive wiring connector types is important. They help car electrical systems work well. Each type has a job to do, helping the car run safely. When picking connectors, think about what they are made of and if they fit with other parts.

Anonymous User, who has built wire harnesses for 20 years, says: "Deutsch connectors are great. They come apart easily and can be added to. Plus, they handle power washers."

This shows why choosing the right connectors matters for making systems better. By picking wisely, you can make car systems last longer and work better.

See Also

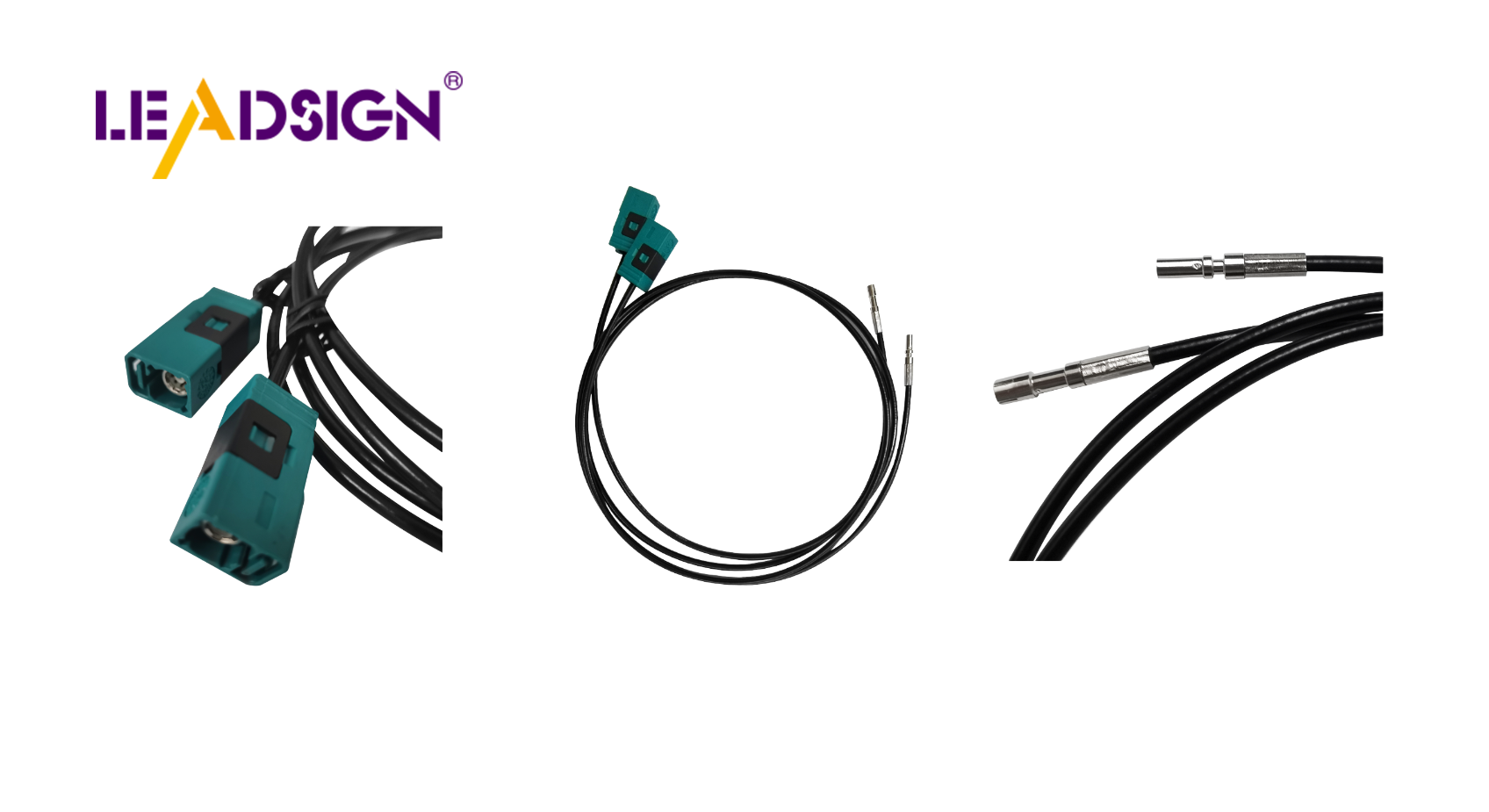

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System