Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in today's vehicles. They ensure that car systems function efficiently by facilitating seamless electrical connections between components. Without these connectors, cars would frequently encounter electrical issues. They protect connections from vibrations and environmental factors, making them resilient against harsh conditions. Their design allows for easy installation and maintenance, underscoring their significance in automotive manufacturing. Understanding these types of connectors highlights their essential role in enhancing the reliability and performance of vehicles.

Types of Automotive Electrical Connectors

Knowing different car electrical connectors is important for fixing cars. These connectors help car systems work well. Let's look at some common connector types used in cars.

Blade Connectors

Features and Applications

Blade connectors, called spade terminals, are simple and useful in cars. They have a flat metal piece that fits into a slot. This makes connecting easy and quick, good for when you need to unplug often. Blade connectors are used in low-voltage places and come with or without insulation.

Common Uses in Vehicles

In cars, blade connectors are found in lights like headlights. They also connect wires to switches and relays. They are easy to use and reliable, making them popular for many car connections.

Pin Connectors

Features and Applications

Pin connectors are another important type of car connector. They have pins that fit into sockets for a strong connection. Pin connectors work well where space is tight but many connections are needed. They handle both small and large electric currents.

Common Uses in Vehicles

Pin connectors connect engine parts to the main computer, like sensors. This helps send data correctly, keeping the car running well.

Ring Connectors

Features and Applications

Ring connectors have a round metal ring that goes over bolts or screws for a strong hold. They're tough and can handle lots of electricity. Ring connectors are used where safe grounding is needed.

Common Uses in Vehicles

In cars, ring connectors link battery cables and grounding wires securely. This keeps the car's electric system working right.

Butt Connectors

Features and Applications

Butt connectors are important in car wiring. They join two wires end-to-end for a steady electric flow. These connectors are shaped like a tube and made from strong stuff like nylon. Inside, there's a metal tube that holds the wires tight. They often have insulation to keep them safe from weather and stop short circuits. This makes them good for tough places, like in cars.

Key Features:

Strong Build: Made to handle shakes and heat changes.

Insulation: Keeps out water and dirt.

Easy to Use: Simple design for fast setup.

Common Uses in Vehicles

In cars, butt connectors are very useful. They connect different parts of the car's wiring system. For example, they help headlights and taillights work by joining their wires. They're also used when adding new things like sound systems or GPS devices. You don't need to solder with them, so they're popular for car jobs.

Common Applications:

Lighting Systems: Makes sure lights stay connected.

Aftermarket Accessories: Helps add new gadgets easily.

Engine Parts: Links sensors and important bits to the car's power.

Butt connectors help fix and keep car wiring working well. They're easy to use and reliable, making them key for keeping car electronics running smoothly.

Key Makers and Brands

Knowing the top companies in car connectors helps pick the right ones. Big names like TE Connectivity and Molex lead this area.

Top Company Overview

TE Connectivity

TE Connectivity is a world leader in making car connectors. They have many products that keep car connections strong. Their connectors last long and handle tough weather well. TE focuses on new ideas to match the changing car industry.

Molex

Molex is also big in car connectors. They make different types for various uses in cars. Molex gives good customer help and smart solutions, like board-to-board links. Their skill makes them a trusted choice for many car makers.

New Ideas and Trends in Connector Design

Car tech changes fast, so do connector designs. New ideas shape how cars connect now and later.

Recent Tech Changes

New tech has made better connectors with high performance. Now, they can handle more data and heat. These changes keep car systems working well even when it's tough.

Future Connector Trends

In the future, car connectors will get smaller and smarter. As cars get more connected, we'll need better communication links. Makers will keep inventing to meet new car needs.

How to Install and Care for Connectors

Installing car connectors right helps them work well and last long. Here’s a guide on tools, steps, mistakes to avoid, and care tips.

How to Install Right

Tools You Need

To put in car connectors well, you need some tools:

Wire Strippers: Take off wire covers without breaking them.

Crimping Tools: Attach connectors to wires tightly.

Screwdrivers: Tighten screws on some connectors.

Multimeter: Check if connections work and have power.

Steps to Follow

Get Wires Ready: Strip half an inch of cover from wire ends.

Pick the Connector: Choose the right connector like blade or pin type.

Attach the Connector: Put wire in connector and crimp it tight.

Check Connection: Use multimeter to see if connection is good.

Make Secure: If needed, tighten screws with screwdriver.

Mistakes Not to Make

Bad Crimping

Bad crimping makes weak connections that can fail. Use the right tool and way for strong fits.

Too Tight Screws

Too tight screws can break threads or connectors. Just tighten enough to hold safely.

Tips for Long Life

Check Often

Look at car connectors often for wear or damage signs like rust or loose wires.

Keep Clean

Keep connectors clean from dirt and wetness. Use a brush or air spray for cleaning. In tough spots, use covers or sealants.

Following these steps keeps car connectors working well longer. Good care stops problems before they start and keeps cars running smoothly.

Picking the right car wiring connector is very important. Each type does a special job, and choosing the right one helps electricity work better. Installing and taking care of them well makes them last longer. Checking them often and caring for them stops problems. Good connectors help cars run well by keeping connections strong. They make sure everything works right, which keeps the car safe and reliable. Knowing this helps cars last longer and makes drivers happy.

See Also

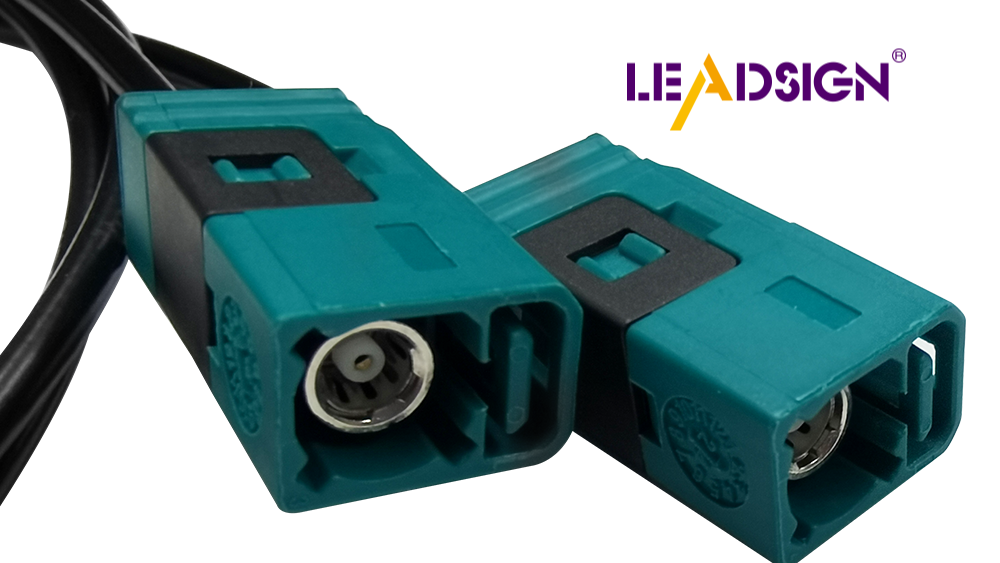

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors