Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles. They ensure that the car's electrical components function efficiently by securely linking various parts. These connectors maintain the reliability of the car's circuits, which is vital for the vehicle's performance and safety. Without these connectors, electrical systems could fail, leading to potential hazards. Understanding automotive electrical connectors types aids in selecting the appropriate ones for each application, ensuring that car systems operate effectively and have a long lifespan.

Features of Automotive Wiring Connectors

Material Composition

Common materials used

Car wiring connectors use different materials for strength and work well. Usual materials are:

Nylon: Flexible and tough against scratches.

Polypropylene: Light and handles chemicals well.

Thermoplastic Elastomers (TPE): Stretches and survives bad weather.

These materials help connectors work better in cars.

Advantages and disadvantages of each material

Each material has good points and bad points:

Nylon:

Advantages: Strong pull strength, wears out slowly.

Disadvantages: Soaks up water, which can cause problems.

Polypropylene:

Advantages: Light, fights off many chemicals.

Disadvantages: Breaks easier than other stuff.

Thermoplastic Elastomers (TPE):

Advantages: Bends easily, resists hot or cold.

Disadvantages: Costs more than others.

Knowing these helps pick the right one for car jobs.

Design Specifications

Connector shapes and sizes

Car wiring connectors have different shapes and sizes to fit needs. Usual shapes are:

Rectangular: Used for many pins together.

Circular: Strong links in small spots.

Blade: Fast and simple connections.

Connector size depends on pin number and needed power flow.

Importance of design in functionality

Connector design affects how it works. A good design gives:

Secure Connections: Stops accidental unplugging.

Ease of Use: Easy to put in or take out.

Compatibility: Fits the system's needs well.

Design is key for reliable car wiring systems.

Durability and Reliability

Factors affecting durability

Many things affect how long car connectors last:

Material Quality: Better stuff lasts longer.

Environmental Exposure: Fights water, heat, chemicals to last longer.

Mechanical Stress: Good design lessens wear from shakes or moves.

These decide how a connector holds up over time.

Testing standards for reliability

Car wiring connectors face tough tests to be sure they work well. Usual tests are:

Vibration Testing: Checks if it handles shaking stress.

Temperature Cycling: Tests under hot or cold changes.

Corrosion Resistance: Sees if it stands up to damage outside.

Following these makes sure connectors do their job right in cars.

Types of Car Wiring Connectors

Blade Connectors

What they are and how they're used

Blade connectors, also known as spade connectors, have a flat metal piece. This fits into a matching slot. They make connections fast and easy. That's why they're common in cars. Mechanics use them where parts need to be unplugged often, like fuse boxes.

Good and bad points

Blade connectors have benefits. They are quick to put in or take out, saving time during fixes. Their shape keeps them snug, so they don't fall out easily. But there are downsides too. They can loosen from shaking, causing weak links. Also, they aren't great for high power because the contact area is small.

Pin Connectors

What they are and how they're used

Pin connectors have one or more pins that go into sockets. They're flexible and used in many car systems like engine controls. Pin connectors help send signals and power between parts so the car runs well.

Good and bad points

Pin connectors give strong connections and fit many wires in small spaces. They're perfect for tight spots in complex wiring jobs. Their design helps avoid wrong hookups, boosting reliability. But installing them can be tricky without the right tools. They need exact alignment for a good fit, which takes time.

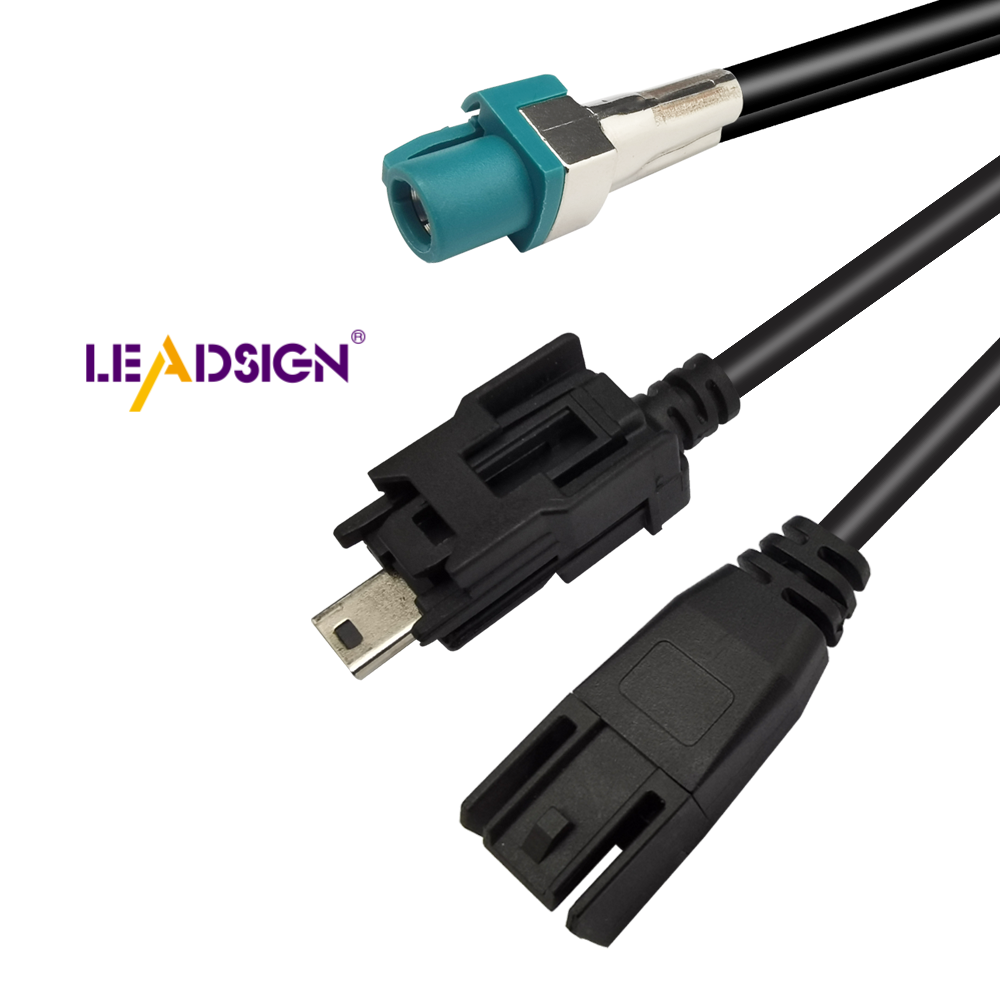

Special Connectors

What they are and how they're used

Special connectors are made for certain jobs with special features like waterproofing or high-speed data transfer for tech systems in cars.

Good and bad points

Special connectors solve unique car needs well by working better under specific conditions like wetness or fast data needs but cost more than regular ones due to their special designs; finding replacements might be hard since they're not as common.

Leading Makers

TE Connectivity

Product Overview

TE Connectivity is a big name in car connectors. They make many products for cars. Their connectors keep car parts connected safely and work well. People like their products because they last long and are reliable.

Market Standing

TE Connectivity is known for good quality and new ideas. They always make things that match car needs. They focus on research to stay ahead and help modern cars work better. Customers trust them because they know a lot about making great products.

Delphi Technologies

Product Overview

Delphi Technologies makes many types of car connectors too. Their products help cars run safely and better. These connectors are simple to use and last long, fitting many car parts from engines to radios.

Market Standing

Delphi Technologies is famous for smart ideas and top products. They have many happy customers by giving good solutions all the time. Their care for the planet and new tech keeps them strong in the market. Many car makers trust them as partners.

Installation Techniques

Getting Ready

Tools You Need

Before you start, gather your tools. You will need:

Wire strippers: To take off wire covers.

Crimping tool: To attach connectors to wires.

Screwdrivers: For screws.

Multimeter: To check electric links.

Heat gun: For shrinking connectors.

Having these makes work easy.

Staying Safe

Being safe is important. Follow these steps:

Unplug the car battery to stop shocks.

Wear goggles for eye safety.

Use gloves to avoid cuts and burns.

Keep your workspace bright and tidy.

Check connections twice to stop shorts.

These keep you safe while working.

How to Install

Joining Wires

To join wires, do this:

Strip wire ends with strippers, showing 1/4 inch bare wire.

Put the bare wire in the connector's sleeve.

Use a crimper to press the connector on tight.

Do it again for other wires if needed.

Good connections make things work well.

Locking Connectors

Locking them is key for strong links. Do this:

Line up the connector with its socket or spot.

Push it in until it clicks or locks tight.

Tighten screws with a screwdriver if needed.

Heat shrink connectors with a heat gun for extra hold.

Locked connectors stay put and work better.

Fixing Problems

Finding Bad Links

Bad links can mess things up. Find them by:

Checking connectors for breaks or rust.

Using a multimeter for checking power flow and voltage.

Listening for weird noises like buzzing or clicking sounds.

Finding problems early stops bigger issues later.

Fixes and Repairs

Fix common problems like this:

Clean rusty parts with cleaner spray.

Swap broken parts with new ones.

Tighten loose parts using tools right away.

Re-crimp or re-solder if needed.

Doing these fixes keeps everything running smoothly.

Choosing the right car wiring connector is very important. It helps keep the car's electrical systems safe and working well. Different connectors have their own good and bad points. So, it's important to pick the right one for each job. New connector technology makes them work better and last longer. These changes help cars run more smoothly and meet new needs. Knowing about these changes helps people choose wisely, making cars work better for a long time.

See Also

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors