Understanding Automotive Wiring Connector Types

Automotive electrical connectors play a crucial role in modern cars. They facilitate the transfer of data between sensors, controllers, and various components within the vehicle. These connectors are essential for maintaining the optimal functioning of the car's electrical system. As automotive technology advances, the demand for more sophisticated wiring systems increases. Different types of automotive electrical connectors are available to enable communication between various car parts and external networks. These connectors come in diverse shapes and sizes to cater to specific requirements. With the increasing reliance on centralized data processing in vehicles, understanding the various automotive electrical connectors types is vital for ensuring efficiency and safety on the road.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are important in car systems. They link electrical circuits together. These connectors help sensors and controllers share data. By joining car wires, they stop damage from shaking, heat, or rust. Car connectors come in many shapes and sizes for different needs.

Why are Connectors Important in Vehicles?

Cars change to handle new tech with new designs and connectors. Picking the right connector maker is crucial for tough places like heat or cold. Bad materials can cause weak links, hurting things like GPS or music systems.

Basic Components of Connectors

Pins and Sockets

Pins and sockets make up a connector's heart. Pins are male parts; sockets are female parts. Together they let electricity flow safely. Their design makes them fit tightly to avoid losing contact. This tight fit keeps connections strong even when things shake or move.

Housing and Insulation

Housing protects pins and sockets from dust or damage. Insulation stops electric shorts by keeping parts apart. It also helps them handle heat without breaking down. Housing and insulation make connectors last longer for many car uses.

Types of Automotive Electrical Connectors

Knowing about different automotive electrical connectors is important. They help connect car parts safely. These connectors protect against weather and other problems.

Blade Connectors

Features and Applications

Blade connectors are also called spade connectors. They are flat and thin, fitting into slots easily. People use them in cars because they are simple to use and fit well. These connectors join wires to switches or relays quickly.

Advantages and Disadvantages

Advantages:

Easy to attach or remove without tools.

Hold connections firmly.

Come in many sizes for different wires.

Disadvantages:

Might loosen if not secured well.

Not good for places that shake a lot.

Ring and Spade Connectors

Features and Applications

Ring and spade connectors are popular for their strength. Ring ones make a circle, bolting down tightly. Spade ones have a fork shape, easy to put on or take off without removing bolts fully.

Advantages and Disadvantages

Advantages:

Give strong connections.

Simple to put on or take off.

Good for high-power uses.

Disadvantages:

Need tools to install or remove.

Ring types need full disassembly to take off.

Butt Connectors

Features and Applications

Butt connectors look like tubes joining two wire ends together. They fix or change car wiring often. Crimping them onto wires makes the connection safe with insulation.

Advantages and Disadvantages

Advantages:

Make strong, lasting links.

Stop short circuits with insulation.

Great for fixing or making wires longer.

Disadvantages:

Need crimping tools to set up.

Hard to remove once attached.

Specialty Connectors

Specialty connectors in cars meet special needs. They work well even in tough conditions. These connectors keep car wires safe, especially in bad weather.

Weatherproof Connectors

Weatherproof connectors protect car wires from rain, dust, and heat changes. They are important for cars in different climates. These connectors have seals to stop water from getting in and hurting the wires.

Features:

Sealed to keep out water.

Strong materials for hot or cold weather.

Protect against dust and dirt.

Applications:

Used for outside lights.

Needed for off-road cars.

Common on boats where water is a problem.

Weatherproof connectors show how car connectors can change to make cars safer and more reliable.

High-Temperature Connectors

High-temperature connectors handle very hot places like near engines. They stay strong even when it's really hot, keeping the electric flow steady.

Features:

Materials that don't melt or change shape.

Work well even when it's very hot.

Insulation that handles high heat.

Applications:

Used near engines.

Good for fast cars.

Great for places needing heat protection.

High-temperature connectors show how car connectors can be used in hot spots to keep connections working well.

Picking the Right Connector

Choosing the right automotive wiring connector is very important. It helps keep a car's electrical system working well. Here are things to think about and mistakes to avoid.

Things to Think About

Electrical Needs

Current Capacity: Know how much current the connector needs to handle. Pick connectors that can carry electricity without getting too hot.

Voltage Rating: Make sure the connector's voltage matches what the system needs. Wrong voltage can cause problems.

Signal Integrity: For sending data, use connectors that keep signals clear. Fast data connectors like HSD are best for less signal loss.

Environmental Conditions

Temperature Range: Think about how hot or cold it gets where you use it. Hot places need high-temperature connectors.

Moisture and Dust Protection: In wet or dusty spots, weatherproof connectors are needed. They stop rust and keep connections safe.

Vibration Resistance: If there’s shaking, get connectors that stay connected even with movement.

Mistakes to Avoid

Wrong Size

Mismatched Sizes: Don’t use connectors that don't fit wires right. Wrong size means bad connections and possible failures.

Overloading: Never go over what a connector can handle. Too much load causes heat and damage.

Bad Materials

Substandard Materials: Cheap materials make connectors fail early. Choose strong ones with good insulation.

Lack of Proper Insulation: Make sure there's enough insulation to stop short circuits, which makes them last longer and safer.

By thinking about these points and avoiding mistakes, people can make sure their car wiring works well, keeping cars safe and functional.

Picking the right car wiring connector is very important. Connectors keep a car's electrical system strong. They help data move well and guard against weather problems. Car experts say buyers and suppliers should work together. This teamwork makes good plans for testing connectors. A design partner looks at weather to make systems better. By choosing good connectors, cars can be safer and work better on roads.

See Also

Exploring HSD Connectors in the Auto Sector

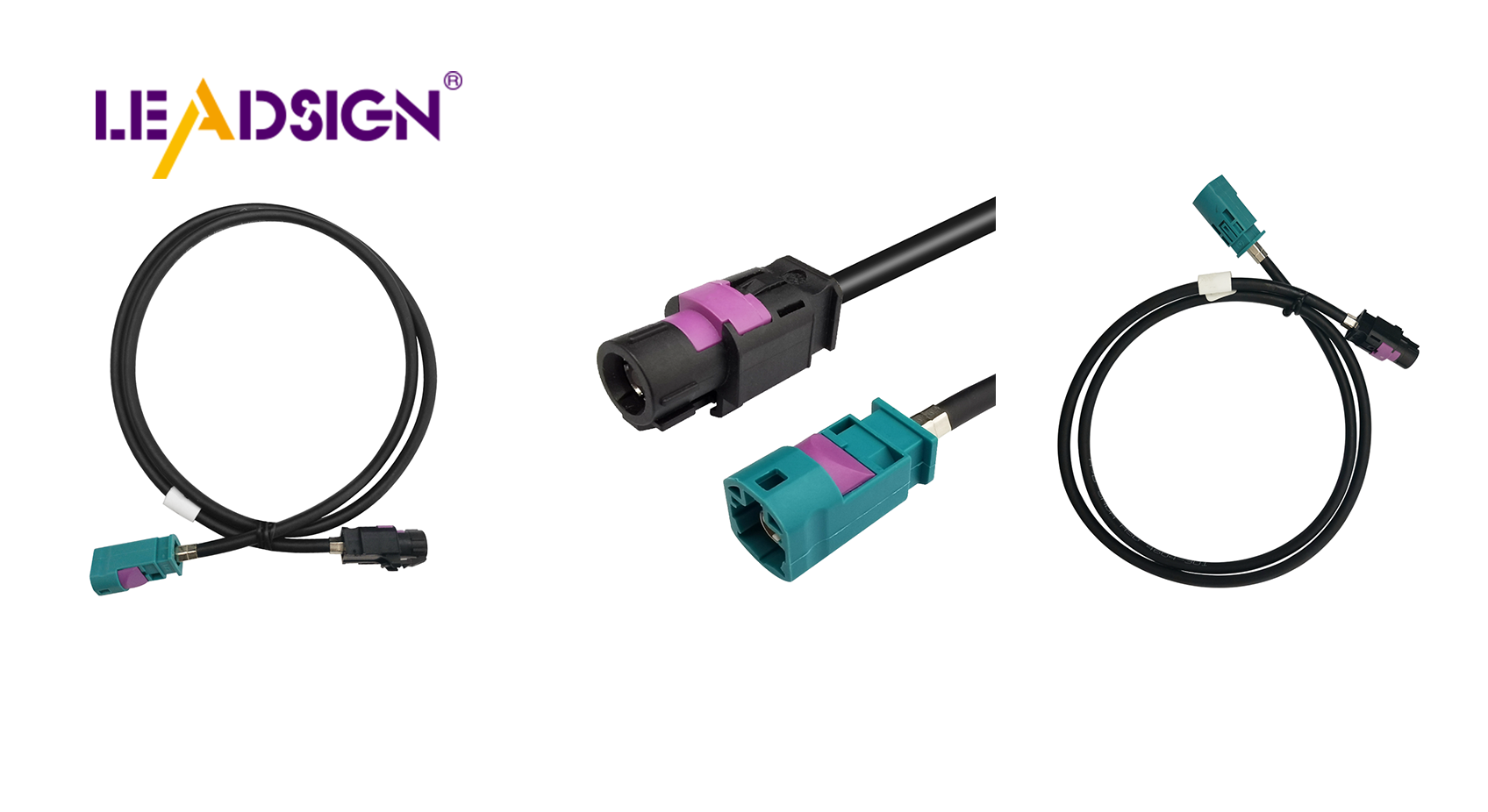

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System