Understanding Automotive Wiring Connector Types

Automotive wiring connector types play a crucial role in modern vehicles. They facilitate seamless communication between various electrical components. With some cars containing as many as 700 connectors and over 3,000 wires, the importance of these connectors cannot be overstated. They efficiently transmit power and data, ensuring the smooth operation of the vehicle. The diverse range of automotive wiring connector types contributes to the resilience of the car's electrical system. As automotive technology advances, the significance of these connectors becomes increasingly evident in the automotive industry.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are key parts in a car's electrical system. They link circuits to send electrical signals smoothly. Each connector has male (plug) and female (socket) parts. Their design changes based on use, like needing bigger pins for high power.

Why are they important in vehicles?

In cars, wiring connectors help electronic parts talk well. They make sure power and data move easily, keeping the car working right. Without them, wires wouldn't work well, causing problems.

Components of Wiring Connectors

Pins and sockets

Pins and sockets are main parts of any connector. Male pins go into female sockets for a strong link. They're made from copper or brass for good conductivity and no rust. This makes sure connections last through tough conditions.

Housing and insulation

The housing and insulation keep parts safe from harm and weather. The housing gives support, while insulation stops shorts and adds safety. Modern connectors are strong and simple to put together, ensuring they last long in cars.

Historical Background and Changes

Early Beginnings

First designs and materials

At first, car wiring connectors were basic. Makers used copper and brass. These metals worked well but didn't last long. The first designs focused on working, not looks or efficiency. As cars got more complex, better connectors were needed.

Changes over time

Over time, car wiring connectors changed a lot. In the 1960s, standard connectors became common. This made swapping parts easier and faster to build cars. With new tech, connectors got smaller and better. They became more reliable for modern cars. The change in wire connector types shows how car tech has grown.

New Ideas Today

Better materials and tech

Now, car wiring connectors use new materials and tech. Makers use strong plastics and alloys for longer-lasting parts. These materials don't rust and handle heat well. Modern connectors also have smart tech for quick data sharing, making cars run better.

Tech's effect on design

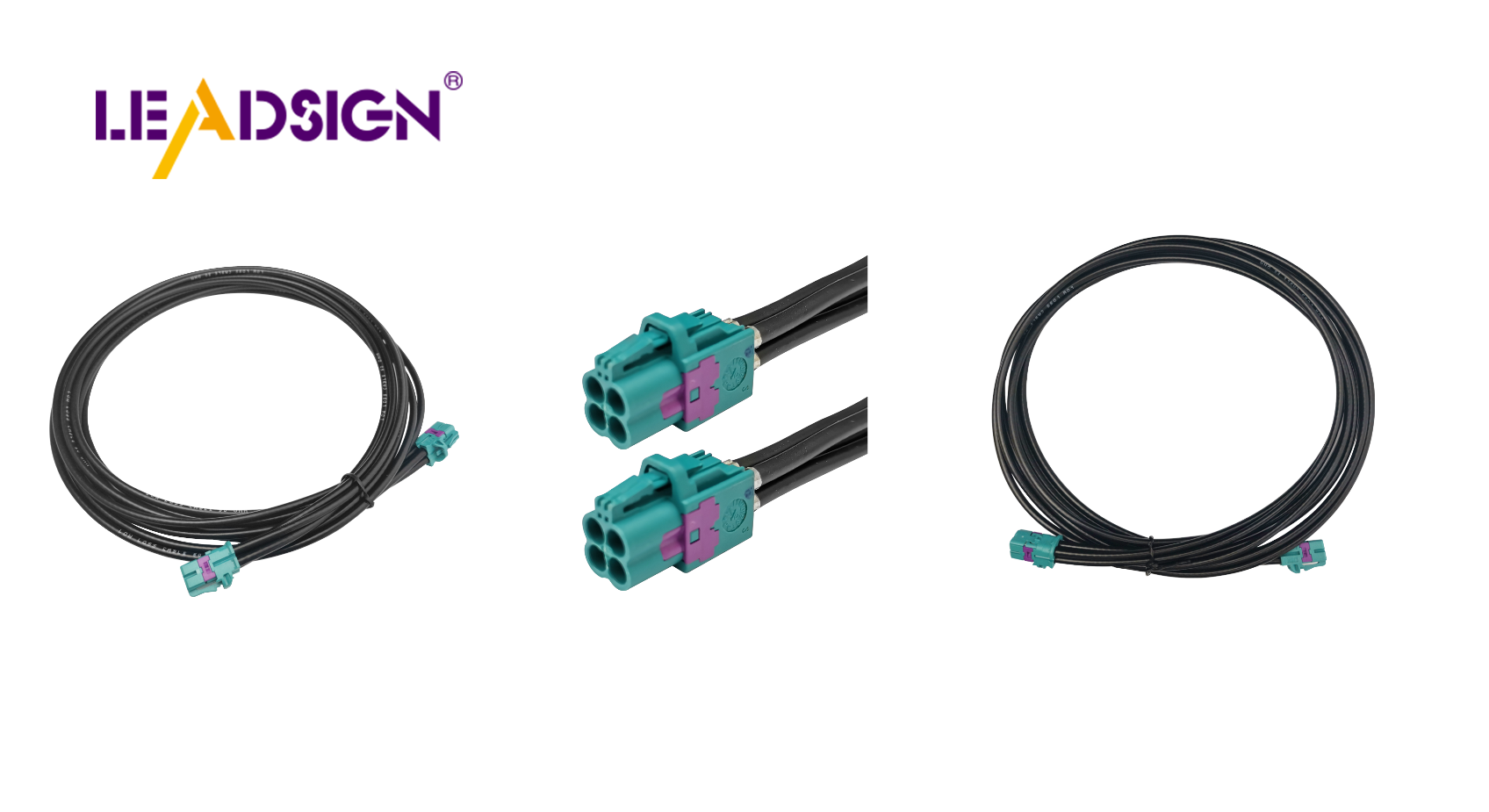

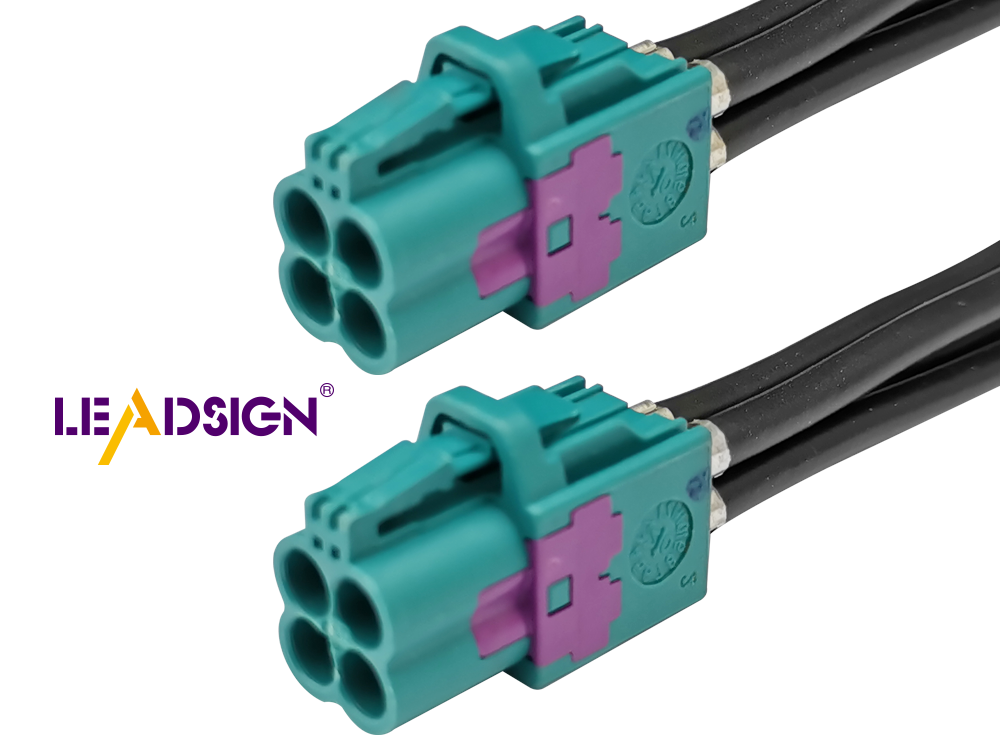

Tech has changed how car wiring connectors look. Designers now focus on saving space with modular systems. This helps fit more parts in small spaces in cars. High-speed data connectors like High-Speed FAKRA-Mini show this change. They handle fast data for self-driving and entertainment systems in cars. As tech grows, wiring connector designs will keep improving safety and performance.

Types of Automotive Wiring Connectors

Knowing different automotive wiring connector types is important for car electronics. Each type has its own job and benefits.

Blade Connectors

What they are and how they're used

Blade connectors, also called spade connectors, have a flat metal piece. This piece fits into a matching slot. They are often used in cars for quick connections. These connectors are great when you need to unplug things often, like in fuse boxes.

Good and bad points

Blade connectors have some good points:

Easy to use: Fast to plug in and out.

Can be used many ways: Works for lots of uses.

But there are also downsides:

Low power limit: Not good for high power.

Might get loose: Can loosen if not tight enough.

Ring and Spade Connectors

How they look and work

Ring and spade connectors make strong, lasting links. The ring goes around a bolt or screw, while the spade slides under it. They're often used for grounding or battery links.

Upsides and downsides

Ring and spade connectors offer:

Strong link: Gives a steady connection.

Lasts long: Handles shakes and tough spots well.

But they also have cons:

Harder to set up: Needs tools to put on.

Not very flexible: Bad for frequent unplugging.

Butt Connectors

How they work and how to set them up

Butt connectors join two wires end-to-end smoothly. They're common in car wiring fixes. To install, strip wire ends, insert them into the connector, then crimp them tight.

Good parts and limits

Butt connectors provide:

Simple setup: Easy with basic tools.

Tight link: Makes a strong electric path.

Yet, they have issues too:

Can't reuse easily: Once crimped, can't use again.

Rust risk: Needs sealing to keep water out.

These wiring connector types help keep cars' electrical systems working well. Knowing their traits helps pick the right one for each job, ensuring reliability.

Installation Techniques

Tools Needed

Important tools for setup

To install automotive wiring connector types, you need special tools. Experts at Wirefy say good tools make strong connections. Here are key tools:

Wire Strippers: Take off wire cover without harming copper.

Crimping Tools: Attach connectors tightly to wires.

Soldering Iron: For soldering, it makes a lasting bond.

Heat Gun: Shrinks tubing for protection and insulation.

Safety tips

Safety is very important with electrical work. Automotive Connector Specialists advise following safety rules to stay safe. Here are some tips:

Disconnect the car battery before starting to avoid shocks.

Wear goggles and gloves for protection from sparks and sharp wires.

Keep the area bright and clear of flammable stuff.

Check connections twice to stop shorts or loose parts.

Step-by-Step Setup Guide

Getting wires ready

Getting wires ready is key for success. Do these steps:

Cut the Wire: Use cutters to make wire the right length.

Strip Insulation: Take off half an inch of cover with strippers.

Twist Strands: Twist copper strands together to stop fraying.

Connecting and securing

After preparing wires, connect them like this:

Pick the Connector: Choose the right type for the job.

Insert Wire: Put stripped end into connector snugly.

Crimp Connector: Use tool to press connector onto wire securely.

Solder Connection (optional): Add solder for extra strength with iron.

Use Heat Shrink Tubing: Slide tubing over connection, shrink with heat gun for safety.

By using these steps and proper tools, people can make strong connections in cars. Good installation helps wiring connectors work well, boosting car performance and safety.

Q&A Section

Common Issues

Fixing connection problems

Automotive wiring connector types can have problems. These issues can affect the car's electrical system. Finding and fixing them helps the car work well. Usual problems are loose connections, rust, and broken pins.

Loose Connections: Look for connectors that are not tight. Reattach them to make things work again.

Corrosion: Check connectors for rust. Clean them with a cleaner to keep them working.

Damaged Pins: Look at pins for bends or breaks. Replace broken ones to keep connections strong.

Wirefy Experts say, "Picking the right connectors is key for good wire connections."

Maintenance tips

Regular care keeps automotive wiring connector types in good shape. Follow these steps to make them last longer:

Routine Inspection: Check connectors often for damage.

Clean Contacts: Use cleaner to get rid of dirt.

Secure Connections: Make sure all are tightly attached.

Protect from Moisture: Use covers to keep water away.

Automotive Connectors Team says, "Good care makes wire connectors last and work well."

Reader Queries

Common questions

What if a connector fails?

Find the problem first. If it's loose, fix it yourself. For hard issues, ask an expert.

How often check my connectors?

Check every few months to find problems early.

Expert advice

Experts give useful tips on keeping and fixing connectors:

iCONN Systems Engineers say, "Wire harnesses are important; don't be cheap with them."

By knowing common issues and listening to experts, people can keep their automotive wiring connector types working well, making cars safer and better performing.

Understanding car wiring connectors is important for keeping a car's electrical system working. These connectors help parts talk to each other, making the car run well. Picking the right connectors for different systems makes sure connections are strong. Knowing this helps people choose better, improving how cars work and stay safe. By learning about these connectors, we can see their importance in today's car technology.

See Also

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors