Understanding Automotive Wiring Connector Types and Standards

Automotive electrical connectors types are crucial components in vehicles. They facilitate the connection of electronic parts without the need for soldering, reducing the risk of electrical issues and damage. This enhances the longevity of a car's electrical system. Modern vehicles utilize wiring harnesses akin to a brain, transitioning from basic wires to sophisticated connectors. These connectors efficiently transmit data and power, expediting the setup process. Adherence to standards guarantees compatibility and safe operation of various connector types, ensuring vehicles operate securely and align with industry requirements.

Basics of Car Wiring Connectors

What are Wiring Connectors?

Wiring connectors are important parts in cars. They join electronic devices without needing to solder, which helps avoid electrical problems and damage. These connectors are part of the car's wiring system, working like a brain. Over time, they changed from simple wires to smart parts that send data and power well.

Why They Matter in Cars

In cars, wiring connectors are very important. They help keep the car's electrical system lasting longer by making it easy to swap out old or broken parts. This makes sure cars work well over time. Also, connectors need to handle tough conditions like those in fast communication systems. Their strength is key for modern cars to work smoothly.

Common Types of Car Wiring Connectors

Blade Connectors

Blade connectors are common in cars. They have a flat metal piece that fits into a slot. This makes connections quick and safe, perfect for many car uses where you often connect and disconnect.

Pin Connectors

Pin connectors have pins that fit into sockets. They give strong connections and are used when exactness is needed in cars. Pin connectors come in many shapes, so they work for lots of uses.

Ring Connectors

Ring connectors are also popular in car wiring. They have a ring end that goes over a bolt or stud for a tight connection. Ring connectors are used for grounding because they last long and install easily. Their shape keeps them steady even with shaking or movement.

Rules for Car Wiring Connectors

Car wiring connectors must follow rules to be safe and fit well. These rules help make connectors work right in cars.

Main Rules Overview

ISO Rule 10487

ISO Rule 10487 is important for cars. It tells how car radio connectors should be made. This rule makes sure they fit and work well, stopping electric problems. By using ISO 10487, makers can create good connectors that are used worldwide.

SAE Rules

The Society of Automotive Engineers (SAE) has many rules for car connectors. These cover what they are made of, how they look, and testing steps. SAE rules make sure connectors handle things like shaking and wetness. Following these helps make sure connectors work well in different places.

Why Following Rules Matters

Keeping Safe

Following rules keeps cars safe. Good connectors stop electric problems that might cause accidents or harm the car. By using set rules, makers can build strong connections even when things get tough.

Making Things Fit Together

Rules also help different car parts fit together easily. When everyone follows the same rules, parts from different places can match up well. This makes fixing cars easier because parts will fit right away. It also helps new tech work with old systems, helping cars get better over time.

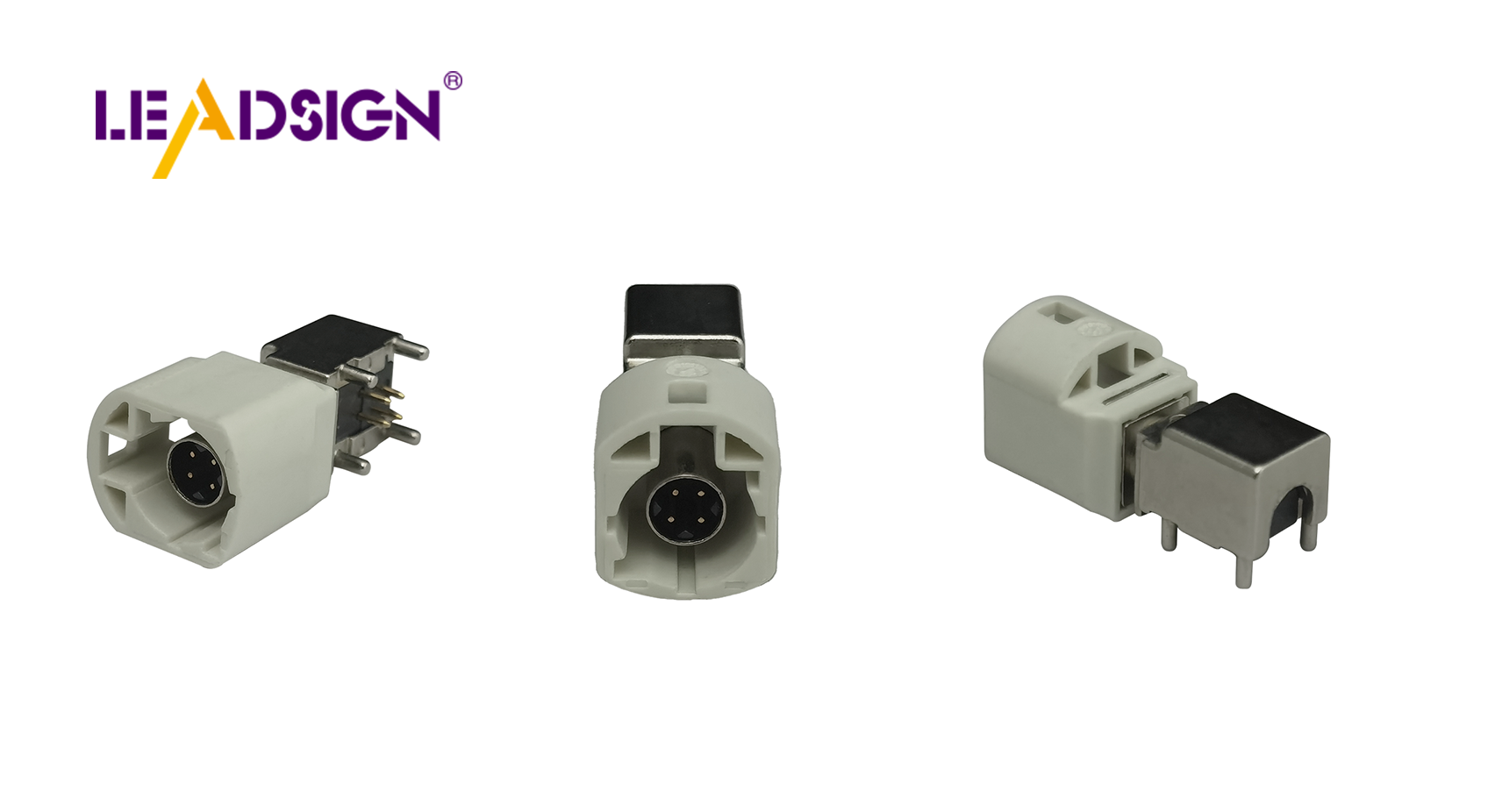

Types of Connectors by Shape and Size

Knowing the shapes and sizes of automotive electrical connectors is important. It helps pick the right connector for each job. The shape and size affect how well it works in different places.

Connector Shapes

Round Connectors

Round connectors are used a lot in cars. They are strong and easy to use. Their round shape makes them tough against dust and water. This is good for rough places in cars. Round connectors fit well where space is tight, making them easy to put together.

Square Connectors

Square connectors have their own benefits. They can hold many connections in a small space. This makes them great when you need lots of links close together. Square connectors are used when exact fits are needed in car wiring systems.

Where Different Shapes Are Used

In Engines

In engines, the connector's shape matters a lot for working well. Round connectors are liked because they last long and handle heat and shaking well. They keep sensors connected safely, which is key for engine checks.

In Lights

Car lights need connectors that can be unplugged often without trouble. Square connectors work here because they stay steady with many wires inside one part. This helps with new light tech like smart headlights.

Picking the right shape for automotive electrical connectors is key to making sure car parts work best and last long.

Knowing about car wiring connector types and rules is important. These connectors join electronic parts without soldering, which lowers the chance of electrical problems. By following set rules, makers make sure connectors work well even in tough conditions like fast communication systems. This helps a car's electrical system last longer and improves how the car works. In the end, understanding these parts and their rules helps people make smart choices about fixing and upgrading cars.

See Also

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors