Understanding Automotive Wiring Connector Types

Understanding the various types of automotive wiring connectors is crucial for repairing vehicles. These connectors serve as the foundation of the electrical systems in cars, facilitating effective communication between different components. They play a vital role in transmitting power and data seamlessly, ensuring the safe and efficient operation of vehicles. Familiarizing oneself with the different automotive wiring connector types can enhance one's ability to troubleshoot and resolve car issues effectively.

Basics of Automotive Wiring Connectors

Definition and Function

What are wiring connectors?

Wiring connectors are key parts in car systems. They link electrical circuits, letting power and data move between vehicle parts. These connectors help each part talk well, keeping the car working right.

Why are they important in automotive systems?

Connectors are vital in cars for safe and strong links. They stop electrical problems and keep things safe by lowering short circuit risks. Good connectors boost car performance and life, making them crucial today.

Historical Evolution

Early developments in automotive connectors

In the 1920s, ready-made wire bundles changed the auto world a lot. This idea made building cars easier and improved electric connections' trustworthiness.

Modern advancements and innovations

Today's connectors have grown to fit new car tech needs. Tough, waterproof ones like "SuperSeal" used in Fiat cars show this growth. These last through tough times, ensuring today's complex cars work well.

Automotive Wiring Connector Types

Knowing different automotive wiring connector types is important for fixing cars. Each type has its own job, with pros and cons. Let's look at some common ones used in cars.

Blade Connectors

Characteristics and uses

Blade connectors, also called spade connectors, are flat and thin. They are popular in cars because they are easy to use. These connectors let you connect and disconnect quickly, which is good for frequent repairs.

Advantages and disadvantages

Blade connectors have many benefits. They make strong connections and are simple to install without special tools. But they might not work well where there's a lot of shaking, as they can come loose. You need to line them up right for a good connection.

Pin Connectors

Characteristics and uses

Pin connectors have a round pin that fits into a socket. They are used in cars because they handle high power well. They are great when you need a tough connection.

Advantages and disadvantages

Pin connectors give strong connections even in hard conditions. They resist shaking and fit many wire sizes. However, connecting them takes more effort than other types, and if not done right, the contact can be bad.

Butt Connectors

Characteristics and uses

Butt connectors join two wires end-to-end. They're often used in car wiring to fix or extend wires. These are best when you need a lasting connection.

Advantages and disadvantages

Butt connectors easily splice wires together safely. They prevent short circuits with their secure link but aren't meant for regular disconnection. You might need extra tools like crimpers to install them properly, sealing them well stops moisture that causes rust.

Ring and Spade Connectors

Characteristics and uses

Ring and spade connectors are key in car wiring. They make strong links for electrical parts. Ring connectors have a round end that fits on bolts or screws, keeping it tight. Spade connectors look like forks, so you can attach or remove them easily without taking out the screw.

These connectors are common in cars for grounding wires and battery connections. Their shape keeps them steady even with vibrations or movement, which is important in cars.

Advantages and disadvantages

Ring and spade connectors have many good points. They give a strong link that stays put, even with shaking. They're easy to put on and take off, helpful for fixing things. They fit different wire sizes, making them useful in many ways.

But there are some downsides too. You need to line them up right when installing to keep them secure. If not done well, they might come loose and mess up the system's work. Also, while spade connectors are quick to disconnect, they might not be best where you need a lasting connection.

Installation Techniques

Installing automotive wiring connector types right makes sure car wires work well and safely. This part tells you what tools you need and how to put the connectors on step-by-step instructions.

Tools Needed

Important tools for putting on connectors

To put on automotive wiring connector types, you need special tools like:

Wire Strippers: These take off wire covers without breaking them.

Crimping Tool: It squeezes connectors onto wires tightly.

Screwdrivers: You use these to tighten or loosen screws on connectors.

Multimeter: This checks if the electric connection works right.

Heat Gun: It helps shrink tubing to keep connections safe.

Safety tips

Safety is very important when working with automotive wiring connector types. Follow these tips:

Disconnect the Battery: Always unhook the car battery before starting to avoid shocks.

Wear Protective Gear: Use gloves and goggles to stay safe from electric risks and sharp tools.

Work in a Bright Place: Good light helps you see clearly and not make mistakes.

Check for Power: Use a multimeter to make sure no power is in wires before working.

Step-by-Step Guide

Getting the wires ready

Cut the Wire: Cut the wire to the length you need with cutters.

Strip Insulation Off: Take off about half an inch of cover from each wire end using strippers.

Twist Wires Together: Twist bare wire ends together for a strong link.

Putting on connectors

Pick Right Connector: Choose the correct connector type based on wire size and use.

Put Wire In Connector: Slide stripped wire into connector until it touches metal inside.

Crimp Connector On Wire: Use crimping tool to squeeze connector onto wire, making it tight.

Checking connection

Look at Connection Carefully: Check that it's tight and lined up right by looking at it closely.

Test With Multimeter: Use multimeter to check if circuit is complete without breaks.

Add Heat-Shrink Tubing Over Connection: Put heat-shrink tubing over connection, then use heat gun so it shrinks, giving more safety.

By doing these steps, people can install automotive wiring connector types well, making sure their car's electrical parts are safe and work properly.

Common Problems

Finding Bad Connectors

Bad connectors can mess up a car's electric system. Signs of trouble are flickering lights, power cutting out, or weird sounds. Mechanics should look for rust, loose parts, or broken covers on connectors. Checking often helps find these problems early.

Fixing Methods

To fix things, first find where the problem is. Use a multimeter to check if electricity flows and measure voltage drops. Make sure connectors fit right and are lined up well. If one seems bad, swap it with a new one. Follow the steps when putting pins in connectors to avoid mistakes.

Tips and Good Habits

Keeping Connectors in Shape

Taking care of connectors makes them last longer. Clean them with special cleaner to get rid of dirt and rust. Use grease that keeps water away to protect them. Wrap wires with tape so they don't move or wear out.

Better Connectors

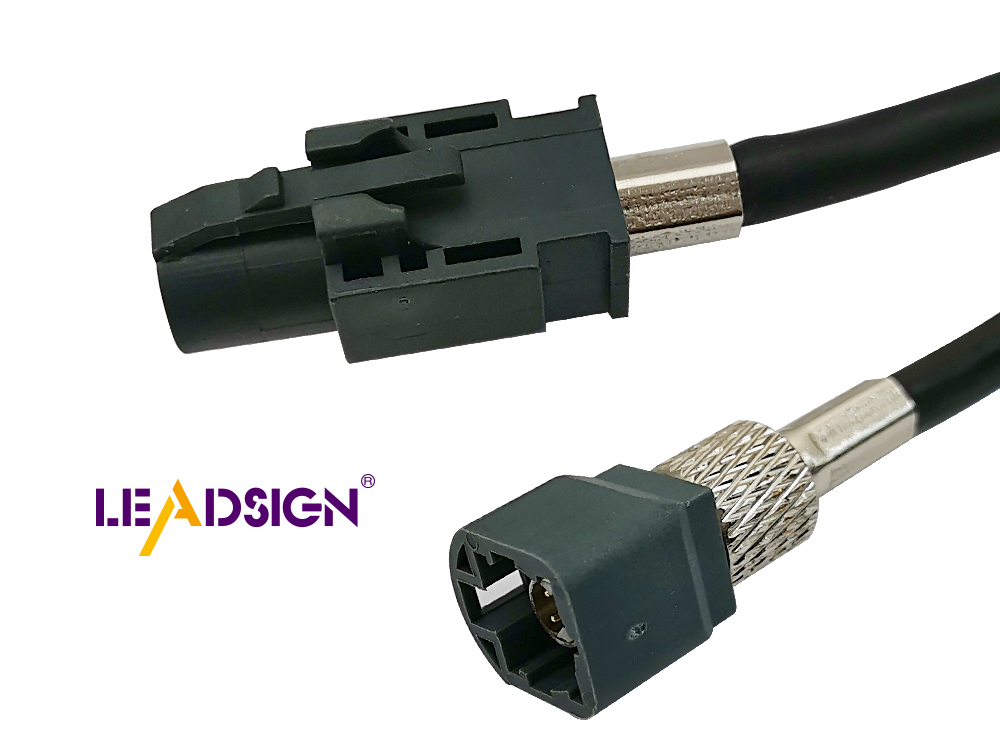

Better connectors make cars work better and more reliably. Think about using ones that seal well for tough conditions. Fast data connectors like HSD help advanced car electronics work well. They hold tight and connect correctly, stopping wrong connections.

Knowing about car wiring connectors is important for fixing cars. This blog talked about different types, what they do, and how to install them. Picking the right connectors keeps cars safe and working well. Using this information helps solve problems and makes cars run better. Use these tips to make smart choices and keep your car's wires in good shape.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System