Understanding Different Automotive Wire Connectors Types

Automotive wire connectors are crucial for your car's electrical system. They enable communication between components, ensuring the vehicle operates efficiently. If these connectors fail, you may experience frequent electrical issues. High-quality automotive wire connectors enhance performance and safety. Understanding the various automotive wire connectors types helps you make informed choices for your car's wiring. This knowledge ensures your vehicle remains safe and runs smoothly, providing peace of mind on the road.

Basics of Automotive Wire Connectors

What Are Wire Connectors?

Definition and Purpose

Wire connectors are key parts in a car's electrical system. They join wires and cables, helping power move between things like batteries and motors. These connectors keep your car's systems running smoothly.

Key Features and Benefits

Automotive wire connectors have many benefits:

Durability: Built to handle tough conditions, they last long.

Reliability: They keep connections steady, lowering electrical problems.

Efficiency: By allowing easy power flow, they boost your car's functions.

Importance in Automotive Systems

Safety Considerations

Wire connectors are important for safety. They stop electrical problems that could be dangerous. Good connectors lower the chance of short circuits and fires, keeping you safe while driving.

Impact on Vehicle Performance

Good connectors make your car work better. They help all electronic parts talk well, aiding features like driver assistance systems (ADAS) and self-driving abilities. This makes driving smoother and more responsive.

Historical Evolution of Wire Connectors

Early Developments

First Designs and Materials

Long ago, car wire connectors were basic but important. They used simple materials like copper and brass. These metals helped electricity flow well and lasted long. The designs were easy, just to connect wires safely for power flow. As cars got more complex, better connectors were needed.

Changes Over Time

Over time, wire connectors changed a lot. Better materials and designs came to meet new car needs. Makers started using plastics for safety and better work. This change let connectors handle more power and resist things like water and heat. So, there were fewer electric problems and cars worked better.

Modern Innovations

New Technology

Today’s wire connectors are very advanced. They help cars talk inside smoothly with power sharing. New ones have fast data moves and strong locks. These help your car's electronics work well all the time. Special connectors now support tech like driver aids and entertainment systems.

Latest Trends

Now, trends in wire connectors aim at performance and being green. There's a move to use earth-friendly stuff that cuts waste down. Also, good connector performance is key for tests to pass rules, especially with certain cables together. This keeps your car up to standards with its warranty safe too. As tech grows, expect even more from these car parts.

Types of Car Wire Connectors

Knowing types of car wire connectors helps pick the right ones. Each type is special and fits different uses.

Pigtail Connectors

What They Are Like

Pigtail connectors are simple and work well. They have a short wire with a connector. This makes them easy to fit into old wires. They last long and handle shakes and heat changes.

Where You Use Them

You use pigtail connectors in car lights. They link headlights, taillights, and other parts fast. Their simple design is great for quick fixes.

Terminal Blocks

What They Are Like

Terminal blocks join many wires safely. They can be added or removed easily because of their design. These blocks keep wiring neat and tidy.

Where You Use Them

In cars, terminal blocks are in dashboards and panels. They help connect electronic parts so they work right. Handling many wires makes them key in tricky setups.

Bullet Connectors

What They Are Like

Bullet connectors make fast connections easy. One end fits into the other snugly. They're simple for making temporary or lasting links.

Where You Use Them

Bullet connectors go where you unplug often. They're used in speakers and audio gear a lot. People like them for being easy to use.

Crimp Connectors

Characteristics

Crimp connectors are simple and strong. They join wires by squeezing a metal piece around them. This makes a tight, lasting link. These connectors resist shaking and rust, perfect for cars. They let electricity flow well.

Durability: Crimp connectors last long in tough places.

Ease of Use: They're quick to put on with the right tools.

Reliability: They keep wires connected, stopping electrical problems.

Common Uses

In cars, crimp connectors do many jobs. They connect battery cables and wire groups. They help your car's electric parts work well. They handle big currents, good for starters and alternators.

Heat Shrink Connectors

Characteristics

Heat shrink connectors seal out water when heated. This keeps connections safe from wetness and dirt. You heat them to make the cover shrink tight around wires. This adds strength and insulation.

Waterproofing: Heat shrink connectors block water, stopping rust.

Insulation: They insulate well, preventing short circuits.

Strength: Shrinking makes connections stronger.

Common Uses

You use heat shrink connectors where it's wet or outside the car. They're great for lights and sensors needing water protection. Their strong seal makes them popular for car wire connections.

Practical Aspects of Wire Connectors

Knowing about automotive wire connectors is important. It helps your car's electrical system work well. This part shows how to install and care for connectors.

Installation Techniques

Tools Needed

To put in wire connectors, you need certain tools:

Wire Strippers: Take off wire covers without harm.

Crimping Tool: Fastens crimp connectors to wires tightly.

Heat Gun: Seals heat shrink connectors to keep water out.

Screwdriver Set: Helps with terminal blocks needing screws.

Multimeter: Tests if connections work right.

How to Install

Putting in wire connectors has steps. Follow these for success:

Get Wires Ready: Strip half-inch of cover from wires.

Pick the Connector: Choose crimp or heat shrink type.

Join the Connector: For crimps, insert wire and crimp it tight. For heat shrinks, slide on and heat until snug.

Check Connection: Use a multimeter for testing faults.

Secure Connection: With terminal blocks, tighten screws well.

Maintenance Tips

Keeping your wire connectors good makes them last longer:

Regular Checks

Look often for early problems:

Look Over Them: Check for wear or damage on parts.

Tightness Check: Make sure all are tight to stop loose links.

Keep Clean: Clean dirt off to keep them working well.

Fixing Common Problems

Fix issues fast to stop bigger ones:

Rusty Parts? Clean them and add protection coat.

Loose Links? Tighten quickly to avoid failures.

Broken Covers? Change bad ones to prevent shorts.

By doing these steps, your automotive wire connectors will work well, making your car safer and better.

Q&A Section

Common Problems

FAQs

When using car wire connectors, you might have questions. Here are some common ones:

Why do my connectors keep coming loose?

Loose connectors happen from not installing them right. Use the correct tools and methods to make them tight.

What causes corrosion on connectors?

Corrosion happens when water and air touch them. Heat shrink connectors can stop this by sealing out water.

How can I identify a faulty connector?

Look for changes like color fading, melting, or burnt smells. These show overheating or bad connections.

Expert Solutions

Experts offer fixes for common car wire connector problems:

For Loose Connectors: Use a crimping tool for a strong hold. Check the connection after putting it in.

For Corrosion: Put dielectric grease to keep moisture away. Check and clean often to stop buildup.

For Faulty Connectors: Change broken ones quickly. Use good quality ones to avoid changing often.

Maintenance Questions

Best Practices

Taking care of your car wire connectors makes them last longer and work well:

Regular Checks: Look at them often for wear or damage. Finding problems early stops bigger issues.

Proper Storage: Keep extra connectors dry and cool. This stops early aging and harm.

Use Quality Tools: Buy good tools for putting them in place. This makes sure they fit right and don’t get damaged.

Long-term Care

For keeping your car wire connectors good over time, try these tips:

Routine Cleaning: Clean with a soft brush to take off dirt and dust. This helps them work well.

Protective Coating: Add a coat to stop rust and corrosion. This makes them last longer.

Avoid Overloading: Don’t let too much current go through them. This stops overheating and breaking.

By doing these things, you can keep your car's electrical system working great!

Knowing about car wire connectors is important for your car's electric system. You learned about types, uses, and how to install them. Pick good and safe connectors first. Ethan Ace, a cable expert, says using the right connector/cable mix is key for working well. Bad connectors often fail tests. ITT Inc. talks about Triton Series connectors that seal better and resist shaking, great for tough places. Always choose strong connectors to keep your car safe and working well.

See Also

Exploring the Fundamentals of HSD Connectors in Automotive Sector

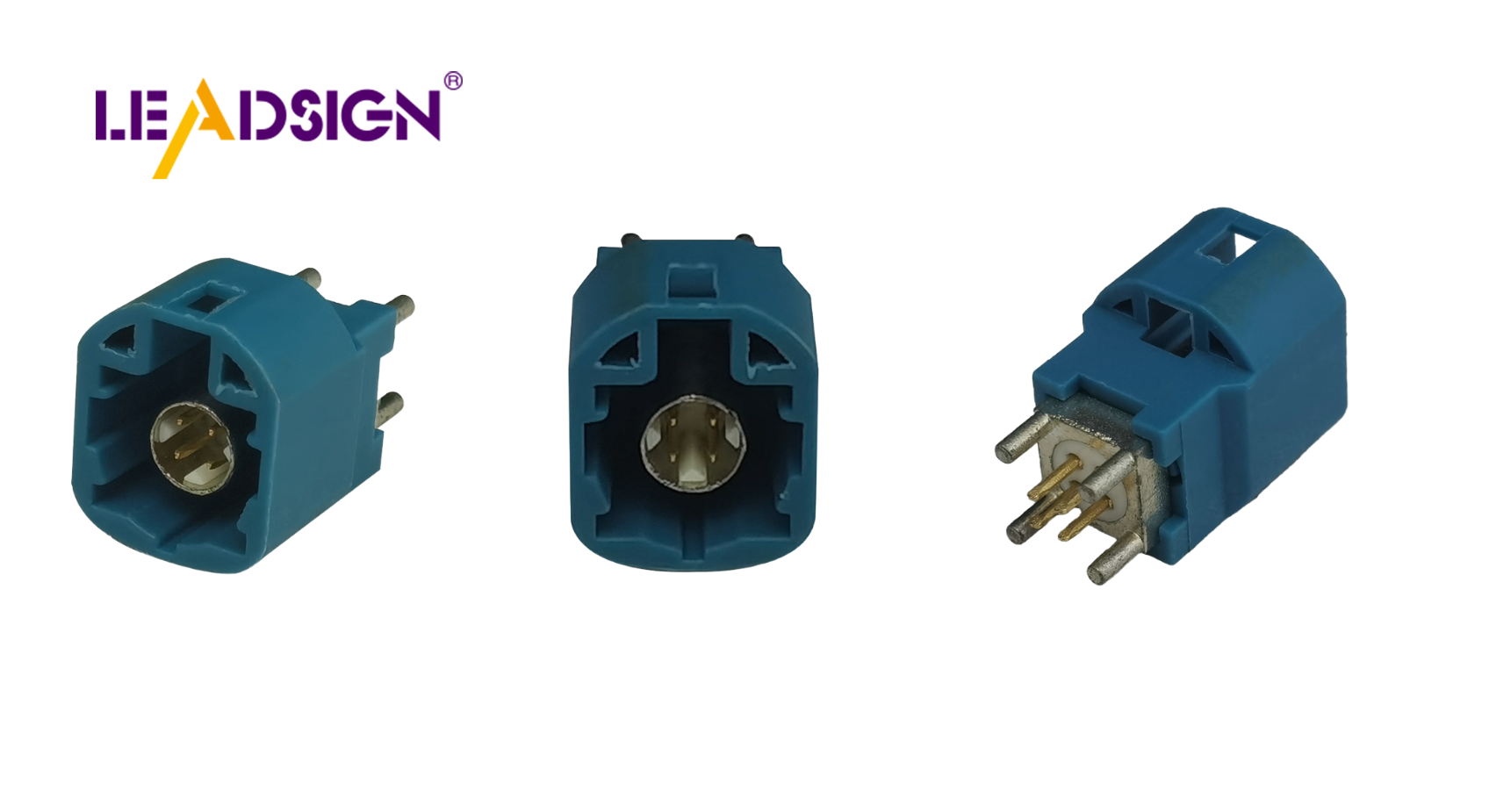

Understanding the Significance of Fakra Connectors in Contemporary Cars

Uncovering the Advantages of Fakra Connectors in Automobiles

Recognizing the Vital Role of Fakra Connectors in Auto Sector

The Significance of FAKRA Connectors in Auto Implementations