Understanding Automotive Wire Connectors Types and Their Uses

Automotive wire connectors are crucial for your car's electrical system, facilitating the smooth transfer of electrical signals between components. These connectors ensure your vehicle operates efficiently and safely. There are various automotive wire connectors types, each designed for a specific function. They protect against vibrations, heat, and corrosion to maintain robust connections. Understanding these connectors helps you maintain your car's electrical systems effectively.

Types of Automotive Wire Connectors

Knowing about different automotive wire connectors helps keep your car's electrical system working well. Each kind has its own job, making sure connections are strong.

Blade Connectors

What Blade Connectors Are Like

Blade connectors have a flat metal piece that slides into a matching slot. This makes connecting them fast and simple. They come in many sizes to fit different wires. Because they are easy to use, people like using them in cars.

How Blade Connectors Are Used

Blade connectors are used when you need to unplug things often. You see them in car radios, lights, and other gadgets. They are great for quick fixes or changes.

Butt Connectors

What Butt Connectors Are Like

Butt connectors look like tubes and join two wires end-to-end. They hold the wires together tightly by squeezing them with a tool. Many have covers to keep out water and rust.

How Butt Connectors Are Used

Butt connectors help when you need to make a wire longer or connect two wires for good. They are important for fixing or changing wire bundles. Their strong build keeps connections safe even if conditions are tough.

Ring Connectors

What Ring Connectors Are Like

Ring terminals have a circle at one end so you can attach them with bolts or screws. Made from metals like aluminum, they give solid connections. You can squeeze or heat them for a snug fit.

How Ring Connectors Are Used

Ring connectors work well for grounding or hooking up wires to blocks of terminals. Their shape ensures they stay put, which is key for important connections in your car's electrical parts.

Spade Connectors

What Spade Connectors Are Like

Spade terminals have a forked end. This shape makes it easy to connect wires. You don’t need tools to use them. They are made from metals like aluminum. The base is hollow, so you can put a wire in and crimp it tight. The spade shape keeps connections strong and allows quick changes.

How Spade Connectors Are Used

Spade connectors are used in many car parts because they are handy. You often see them where wires connect and disconnect a lot. They work well in car radios, lights, and other gadgets. Their design fits small spaces, making sure connections stay secure easily. Knowing about different automotive wire connectors, like spades, helps keep your car’s electrical system working well.

Characteristics of Automotive Wire Connectors

Knowing about automotive wire connectors helps you pick the right one. Let's look at what makes these connectors special.

Material Composition

Common Materials Used

These connectors use metals like copper, aluminum, and brass. These metals carry electricity well and don't rust easily. For instance, spade terminals and ring terminals use them for strong links.

Impact of Material on Performance

The metal affects how a connector works. Copper is great for carrying electricity, perfect for high needs. Aluminum is lighter, helping to cut vehicle weight. Picking the right metal ensures good performance.

Size and Compatibility

Standard Sizes

Connectors have different sizes to fit wires. Standard sizes make it easy to find new ones or upgrades. Knowing your size keeps connections tight.

Compatibility Considerations

Matching connectors with the right wire size is key. This makes sure they fit well and stop electrical problems. Always check compatibility to avoid trouble.

Durability and Reliability

Factors Affecting Durability

Durability depends on material quality and exposure to elements. Connectors need to handle shaking, heat, and wetness. Good materials and proper setup boost durability.

Ensuring Reliable Connections

Good connections need proper setup and care. Use correct tools and follow steps for secure links. Regular checks find wear, keeping your car's system safe.

Practical Uses and Tips

Knowing how to put in, care for, and keep automotive wire connectors safe is key. It helps your car's electrical system work well. This part gives helpful advice on handling these connectors.

How to Install

Tools You Need

To set up automotive wire connectors, get these tools:

Wire cutters

Crimp tool

Heat blower (for heat-shrink types)

Screwdriver (for ring and spade types)

Tester (to check connections)

Having these tools ready makes installing easier.

Easy Steps to Follow

Do these steps to install wire connectors right:

Get Wires Ready: Strip about half an inch of cover from wire ends.

Pick the Connector: Choose the right connector for the job.

Put in the Wire: Push stripped wire into connector until it hits metal.

Crimp It Tight: Use a crimp tool to hold the wire firmly inside.

Seal It Up: For heat-shrink types, use heat blower to shrink wrap around it.

Check Connection: Use tester to make sure connection is good.

Follow these steps for strong and lasting connections.

Care and Fixing Problems

Regular Care Tips

Regular care keeps your connectors working well. Try these tips:

Look at connectors for wear or rust.

Clean them with cleaner spray to remove dirt.

Tighten loose ones to stop electric problems.

Regular care makes connectors last longer.

Fixing Common Problems

Sometimes, problems happen with connectors. Here are fixes:

Loose Fit: Re-crimp or tighten for a snug fit.

Rusty Parts: Clean with spray and add protective layer.

Broken Wires: Swap out bad wires and parts for good ones.

Fixing problems quickly stops more damage.

Safety Tips

Making Safe Connections

Safety matters when using automotive wire connectors. To stay safe:

Always unplug battery before touching electrical parts.

Use right-rated connectors for voltage and current needed.

Double-check tightness and insulation of connections.

These help avoid electric dangers.

Staying Safe from Hazards

Avoid risks by following these rules:

Don’t push connectors past their limits.

Keep them away from hot spots or moving pieces.

Make sure they’re insulated well to stop short circuits.

Following safety tips keeps you and your car safe from harm.

You learned about car wire connectors and their uses. Each type, like blade, butt, ring, and spade, has a special job in your car's electrical system. Picking the right connectors is important for safety. For example, ring terminals stay tight better than spade ones. Always choose good quality and matching connectors. This makes sure your car's electrical parts work well, giving you a safer drive.

See Also

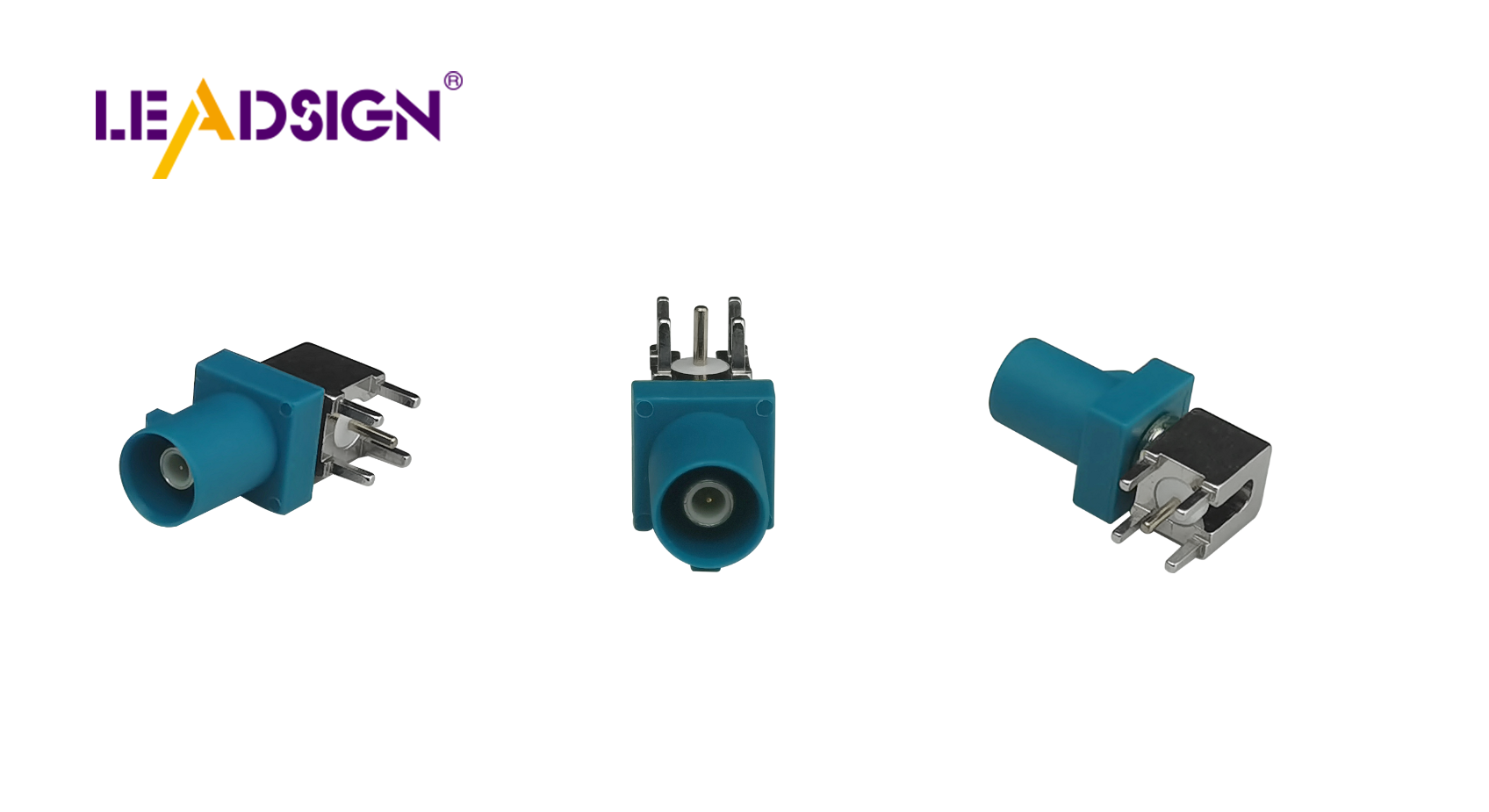

Exploring the Fundamentals of HSD Connectors in Automotive

Understanding the Significance of Fakra Connectors in Modern Cars

Recognizing the Value of Fakra Connectors in Auto Sector