Understanding Automotive Wire Connectors Types and Standards

Automotive wire connectors types are very important in vehicles. They help with communication and power. These connectors must follow strict rules for safety and work well. Rules like ISO and SAE give guidelines to improve quality and stop problems. A strong Quality Management System (QMS) in cars helps reduce product failures. By following these rules, makers ensure automotive wire connectors types are safe and efficient.

Types of Automotive Wire Connectors

Blade Connectors

Features and Applications

Blade connectors are also called flat connectors. They are important in cars and power systems. These have a flat metal piece with a crimping part. You put the blade into a matching block or holder. Then, you crimp it to keep it tight. Blade connectors work well for high power because they are reliable. They come in different sizes and shapes, so they fit many uses.

Advantages and Limitations

Blade connectors have good points. They make strong connections, which is key for high power use. Their design makes them easy to put on and take off, helping with repairs. But there are downsides too. The flat shape might not work in shaky places since it can come loose. Also, if crimped wrong, they may not connect well.

Ring Connectors

Features and Applications

Ring connectors are often used where lots of power flows through wires. They look like circles with holes in the middle to fit on screws or bolts easily. You push the wire through the hole and tighten it with a screw or nut to hold it firm. Ring connectors come in different sizes and materials like copper for various needs.

Advantages and Limitations

Ring connectors give strong connections, great for high power needs. Their shape keeps them from coming loose when things shake or move around. Different materials make them last longer without rusting. But they need careful fitting; if not tight enough, they can be loose.

Butt Connectors

Features and Applications

Butt connectors help join wires together safely. They are tubes with crimp parts at each end where you put wire ends inside then crimp them tight to connect well. Butt connectors fix or extend car wiring easily.

Advantages and Limitations

Butt connectors make joining wires simple by providing solid links that keep circuits working right. They're easy to install for quick fixes but need careful crimping so wires don't get damaged or weakly connected.

High-Speed FAKRA-Mini Connectors

Features and Applications

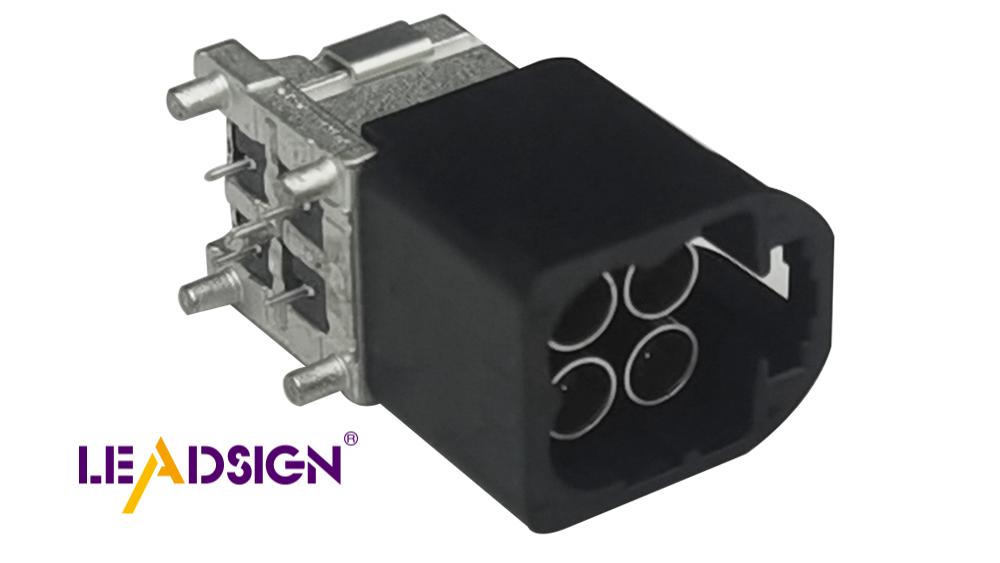

High-Speed FAKRA-Mini Connectors are a big step forward in car wire connectors. They meet the need for fast data transfer in new cars. These can handle up to 20 GHz and 28 Gbps, perfect for quick data sharing.

Their small size saves space, which is key in tight car areas. This lets more parts fit in small spaces, making car electronics work better. They are used in smart driving tech, driver help systems, maps, music systems, and backseat fun.

Advantages and Limitations

The good thing about High-Speed FAKRA-Mini Connectors is they make strong links for high-speed use. Their tiny size saves lots of space, up to 80% less than old ones. Even though small, they stay strong and last long in tough car spots. The design lets them change easily to fit different needs.

But there are downsides too. They need careful setup to work well with high speeds. If not set right, signals can get weak or fail. Also, while they save money over time, buying these new connectors costs more at first than regular ones.

Rules for Car Wire Connectors

World Rules

ISO Rules

ISO makes world rules for car wire connectors. ISO 8092-2005 is a key rule. It helps makers design safe and good connectors. These rules keep things the same everywhere, so cars work well in all places.

IEC Rules

IEC gives more rules for electric parts like wire connectors. IEC rules check how well and safe these parts are. By following them, makers make sure car electric systems work better.

Country Rules

SAE Rules

SAE makes U.S. rules for car wire connectors. These cover both strong and weak power uses, from battery to lights. SAE also has special rules for trailer towing, helping with connector design.

USCAR Rules

USCAR sets tests for car connector systems in the U.S. USCAR-20 shows what makes connectors last long and work well. Following USCAR helps make sure connectors stay strong in tough spots, keeping cars safe.

Importance of Following Rules

Keeping Safe

Stopping Electrical Problems

Following rules for car wire connectors is very important. Rules like ISO 9001-2015 and IATF 16949 help makers keep high quality. By using these rules, companies can stop bad connections that cause electrical problems. This helps keep the car and people safe.

Making Cars Work Better

Rules also help cars work better. Good quality connectors make sure power and signals move well in cars. This means cars run smoothly and use energy well. When connectors follow rules, they support new tech like smart driving, making driving nicer.

Meeting Industry Needs

What the Industry Wants

Following industry rules is not just for safety; it meets needs too. Rules like SAE and USCAR set how strong and long-lasting parts should be. These help makers build connectors that last in tough places.

Why Certification Helps

Certification has many good points. It shows quality and trust to buyers and partners. Certified items often do better in sales. Also, certification pushes for betterment, as seen with standards like ISO 14001 and ISO 45001, which focus on being green and safe at work. This leads to new ideas and growth in the car world.

Picking the right wire connectors is very important for cars. They help with good communication and power flow. Choosing well makes cars work better and safer. Rules like ISO and SAE help makers build good connectors. These rules keep car systems safe and working well. Following them stops electrical problems and helps new tech work. By using these rules, makers make cars safer and better to drive.

See Also

Essential Guide to HSD Connectors in Auto Sector

Significance of Fakra Connectors in Auto Sector

Vital Role of Fakra Auto Connectors in Modern Cars