Understanding Automotive Wire Connectors Types

Automotive wire connectors are crucial for your car's electrical systems. They play a vital role in ensuring all components function harmoniously, contributing to the smooth operation of the vehicle. Without reliable connectors, essential systems such as airbags may fail to operate correctly, compromising safety. Over the years, connectors have evolved to meet the demands of modern vehicles, offering a variety of types designed to withstand challenging conditions, ensuring durability and dependability. Understanding the different automotive wire connectors types highlights their significance in maintaining the safety and optimal performance of your vehicle.

Basics of Automotive Wire Connectors

Definition and Purpose

What are wire connectors?

Wire connectors are important parts of your car's electrical system. They connect wires, making sure they stay together tightly. These connectors come in different shapes and sizes for specific tasks. Using them helps electrical signals move smoothly through your car.

Why are they essential in vehicles?

Wire connectors help keep your car safe and working well. They stop electrical problems by keeping connections strong. Without them, systems like lights, engine controls, and safety features might fail. The right connectors prevent dangers and make sure your car runs properly.

Historical Perspective

Evolution of wire connectors in the automotive industry

Automotive connector history started in the early 1900s. As cars got more complex, good connections were needed more. In the 1950s, many new types of connectors appeared quickly. This was a big change as makers wanted better performance and safety with improved electrical systems.

Key milestones in connector technology

Important events have changed automotive connector development. A big step happened in September 2022 when Sumitomo Electric Industries, Ltd. made the S-LVDS series. This was to meet high-speed data needs for modern cars. With new tech, these connectors allow faster communication between parts, boosting performance and safety.

Types of Car Wire Connectors

Knowing car wire connectors helps you pick the right one. Each kind has special uses and features for certain jobs.

Blade Connectors

What they are and where used

Blade connectors are flat metal pieces that fit into slots. They make quick connections in cars. You see them in fuse boxes and other car parts.

Good and bad points

Blade connectors are easy to use and reliable. But, they can get loose if there's a lot of shaking. Checking them often keeps them tight.

Butt Connectors

What they are and where used

Butt connectors join two wires end-to-end with a metal tube inside. They're used when fixing or making wires longer in cars.

Good and bad points

Butt connectors give strong, safe joins that keep out water. They're great for cars but need special tools to crimp, which can be a problem if you don't have them.

Ring and Spade Connectors

What they are and where used

Ring and spade connectors attach wires to screws or blocks. Rings make circles; spades have open ends for easy use. They're common in battery links.

Good and bad points

Ring and spade connectors are secure and simple to put on. They work well in many car tasks but rings need screws removed first, taking time. Spades go on faster but aren't as tight as rings.

By knowing these wire connector types, your car's electric parts work better. Picking the right one boosts safety and performance.

Installation Techniques

Tools Needed

Important tools for setup

To put in car wire connectors, you'll need some basic tools. These are:

Wire Strippers: Use them to take off the wire cover.

Crimping Tool: This tool helps attach connectors to wires.

Screwdriver: Needed for ring and spade connectors.

Heat Gun: Good for heat shrink connectors to make a tight fit.

Having these tools ready makes installing easier and faster.

Safety tips

Safety is very important when working with car wires. Follow these safety tips:

Disconnect the Battery: Always unplug the car battery first.

Wear Protective Gear: Use gloves and safety glasses to stay safe.

Work in a Bright Place: Make sure you can see well to avoid errors.

Check for Power: Make sure no power is going through the wires.

These steps help stop accidents and keep you safe while working.

Step-by-Step Instructions

Getting the wires ready

Cut the Wires: Use cutters to trim wires to needed length.

Strip the Insulation: Take off about half an inch of cover using strippers.

Twist the Wires: Twist bare wire strands together for a strong link.

Good preparation makes a strong connection.

Linking and securing the wires

Pick the Connector: Choose the right connector type for your job.

Put in the Wire: Insert stripped wire into connector slot.

Crimp the Connector: Use crimping tool to lock wire in place.

Use Heat (if needed): For heat shrink, use heat gun to seal it tight.

By doing these steps, you make sure connections are secure and last long. This helps your car's electric system work better and stay safe too.

Common Issues and Solutions

Troubleshooting Problems

Finding Bad Connections

Your car might have electrical issues from bad connections. Spotting these early saves time and money. Watch for flickering lights or strange noises. These signs mean a loose or rusty connector. Check connectors often for damage or wear. Look out for burnt smells, which show overheating.

Fixing Common Problems

Once you find a bad connection, fix it safely. First, disconnect the battery. Clean rusty connectors with a brush or cleaner. Tighten loose ones with tools. If broken, replace with new connectors that fit your car.

Q&A Section

Common Questions

Why do connectors fail?

They fail from rust, damage, or wrong setup. Weather changes also hurt them.

How often should I check my car's connectors?

Check every six months, but if problems arise, check right away.

Can I use any connector for my car?

No, use ones made for cars to handle tough conditions.

Expert Tips

Automotive Industry Expert: "High-performance connectors help data move between devices in cars."

Tip 1: Pick good-quality connectors for reliable systems like ADAS.

Tip 2: Keep basic tools in your car for quick fixes like wire strippers and crimpers.

By knowing issues and solutions, you can keep your car's electrical system strong. Regular checks and using the right connectors boost safety and performance.

Understanding car wire connectors is important for safety and performance. They help systems like airbags work well. Choose good quality connectors. They last in tough conditions and are strong. Metal connectors are very reliable for key parts. Twisted wire connectors fit well in small spaces. Picking the right ones makes your car safer and better. Check them often to keep everything working right. Learn about them to make smart choices, so your car stays safe and runs smoothly.

See Also

Exploring the Fundamentals of HSD Connectors in Automotive Sector

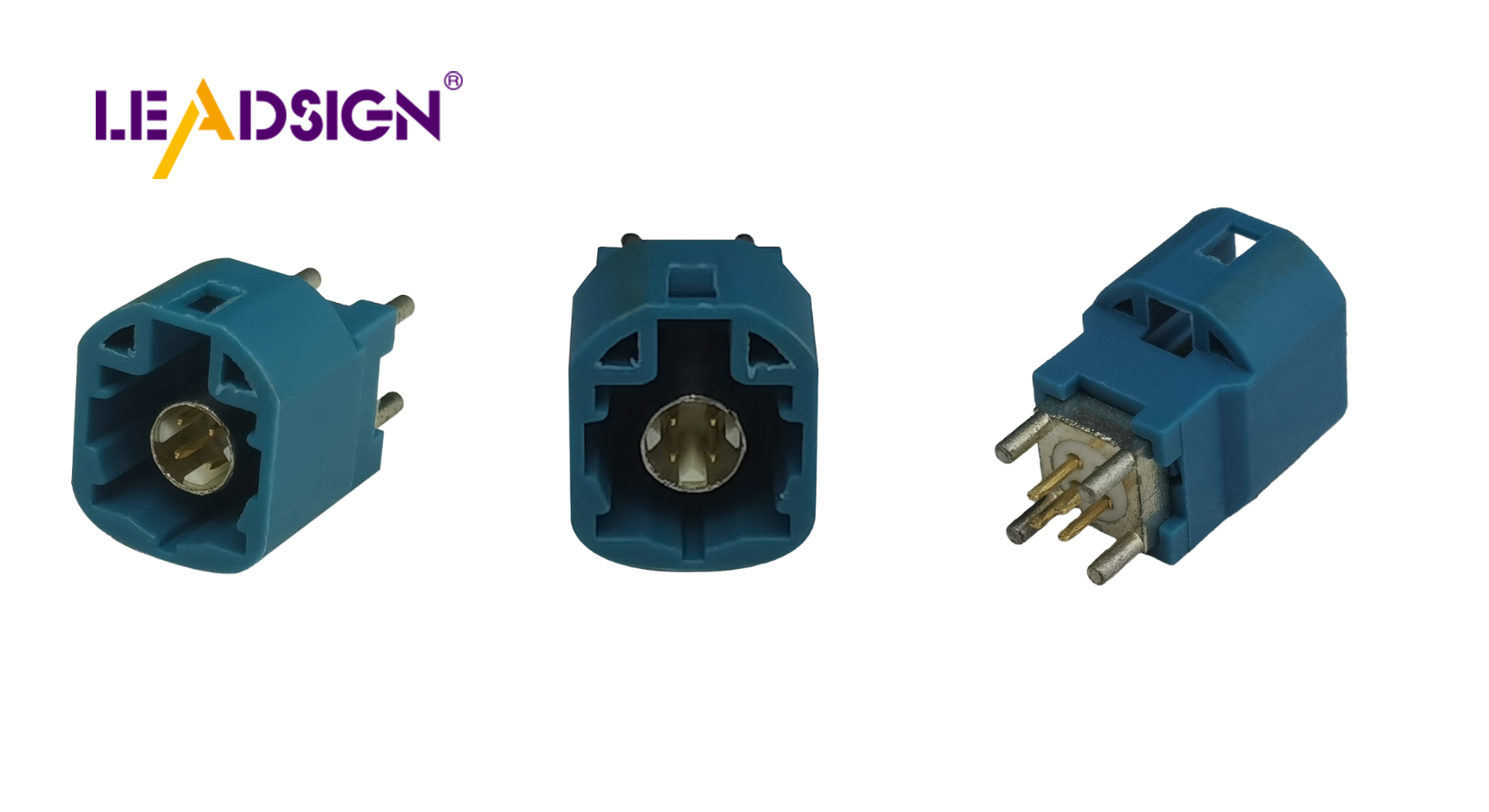

The Significance of Fakra Connectors in Contemporary Cars

The Value of Fakra Connectors in Auto Sector