Understanding Automotive Wire Connectors Types

Automotive wire connectors are important in cars. They help electrical systems work well. Without them, wires could fail easily. Car wire connectors have changed a lot over time. These changes show how they keep cars safe and working well. Knowing about these automotive wire connectors types helps you see how car parts talk and work together.

Basics of Automotive Wire Connectors

Definition and Function

What are Automotive Wire Connectors?

Automotive wire connectors are key parts in a car's electrical system. They link wires so electricity moves easily through the car. These connectors have different shapes and sizes for special jobs. Using the right one makes sure your car's electric parts work well and safely.

Importance in Vehicle Electrical Systems

In cars, wire connectors are very important. They stop wires from getting loose or breaking, which can cause problems. Without them, things like lights and radios might not work right. By keeping connections tight, they help your car run smoothly and safely.

Historical Context

Evolution of Wire Connectors in Automotive Industry

The story of automotive connectors starts in the early 1900s. As cars got better, strong connectors were needed more. In the 1950s, plug and clamp connectors became common. Later, crimp, lock, and quick connectors appeared. These new types made connections better and improved cars' performance.

Technological Advancements Over Time

As cars changed, they added more electric parts. This meant needing better connectors too. Early ones were simple with basic uses. But with things like GPS and control units, they got more complex. Now, modern connectors do many jobs to keep your car's systems working well.

Automotive Wire Connectors Types

Knowing different automotive wire connectors types is important for car care. These connectors help your car's electrical parts work well. Let's look at how they differ by material, function, and design.

Classification by Material

Metal Connectors

Metal connectors are used a lot in cars. They conduct electricity well and last long. Made from copper, brass, or bronze, they resist rust. You find them where strong connections are needed, like the engine.

Plastic Connectors

Plastic connectors are light and cheap compared to metal ones. They're used where weight matters less. Even though they're lighter, they insulate well and protect against weather. They're good for inside wiring with little exposure to harsh conditions.

Classification by Function

Power Connectors

Power connectors handle lots of electricity. They connect big power parts like the battery and starter motor. These connectors spread power well across the car, stopping voltage drops.

Signal Connectors

Signal connectors send data between electronic parts. They're key in cars that use electronics for navigation and entertainment. These connectors need stable links to send data correctly.

Classification by Design

Crimp Connectors

Crimp connectors are easy to use in cars. You press them onto wires without soldering, making quick connections popular with DIYers.

Solder Connectors

Solder connectors give strong bonds by melting solder around wires. This method needs skill but works great where reliability is crucial.

By knowing these automotive wire connectors types, you can choose wisely when fixing your car's electrical systems.

Installation Techniques

Installing automotive wire connectors right makes sure your car's connections work well. This part shows you the tools and steps needed.

Tools Needed

You need certain tools to put in wire connectors. These tools help make strong connections.

Basic Tools for Installation

Wire Strippers: Take off wire covers without harm.

Crimping Tool: Squeeze the connector onto the wire.

Screwdriver: Tighten screws on some connectors.

Multimeter: Check if the connection works right.

Advanced Tools for Pros

Soldering Iron: Melts solder for strong bonds.

Heat Gun: Shrinks tubing to keep connections safe.

Cable Tester: Makes sure there are no problems with the connection.

Step-by-Step Process

Follow these steps to fit wire connectors well.

Preparing Wires

Cut Wire: Use cutters to get the right length.

Strip Insulation: Remove half-inch of cover from each end.

Twist Strands: Twist wires so they fit into connectors easily.

Attaching Connectors

Insert Wire: Put stripped wire into connector snugly.

Crimp or Solder:

Crimp connectors with a tool to squeeze them tight.

For solder, heat iron and add solder for a firm hold.

Secure Connection: Lock them in place to avoid loose links.

Testing Connection

Use Multimeter: Ensure circuit is complete and working.

Inspect Visually: Look for loose or bad connections.

Test System: Turn on car systems to check everything works fine.

By using these steps and tools, you can install connectors safely and well, making your car's electrical parts reliable and safe too.

Common Problems and Care

Fixing Usual Issues

Finding Bad Connections

You might face problems with car wire connectors. Spotting bad connections is key to keeping your car's electric system working. Look for things like flickering lights, broken gadgets, or power going off and on. These signs often mean a connector is loose or rusty. Checking often can help you find these issues early.

Fixes for Usual Problems

Once you find a bad connection, you can fix it. Start by tightening any loose parts. If there's rust, clean it with a wire brush or cleaner spray. For broken connectors, it's best to replace them. Using good quality connectors stops future problems. The Automotive Connector Market focuses on testing and quality checks for safety and trust.

Tips for Care

Regular Checks

Regularly check your car's wire connectors. Look for damage, rust, and if they are tight. This helps stop electric failures and keeps things safe. The Importance of OEM Automotive Electrical Wiring Connectors shows why strong connectors are needed in tough car conditions.

Cleaning and Upkeep

Keeping connectors clean makes them last longer. Use a soft brush or air spray to clear dirt away. For hard-to-remove dirt, use a mild cleaner carefully. Make sure everything is dry before putting back together. Good care not only keeps things working but also makes them safer too. The Automotive Wire Connectors Importance highlights their role in stopping electric failures and keeping cars safe.

By following these fixing and care tips, you can keep your car's electric system in great shape. Regular care helps avoid common troubles so you have a smooth driving time.

Understanding different car wire connectors is very important. It helps keep your car's electric parts working well. Using the right connectors makes sure your car is safe and runs smoothly. Good connectors stop big problems, experts agree. "Buying good connectors is necessary," they say. Not doing this can cause big troubles.

Use what you learn to get better at fixing cars. Ask questions or tell your stories in the comments below. Your ideas might help others with their cars too.

See Also

Exploring the Fundamentals of HSD Connectors in Automotive Sector

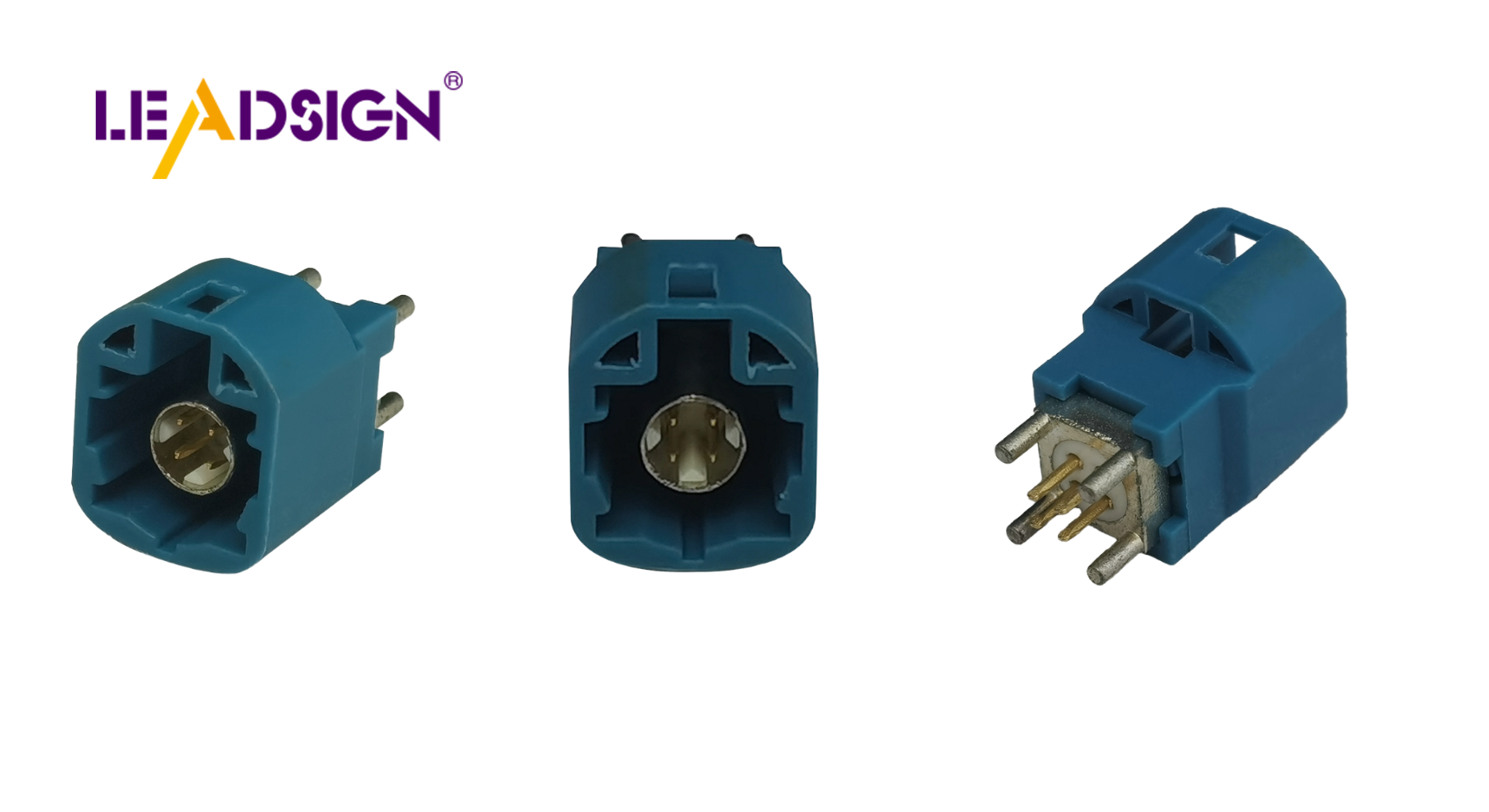

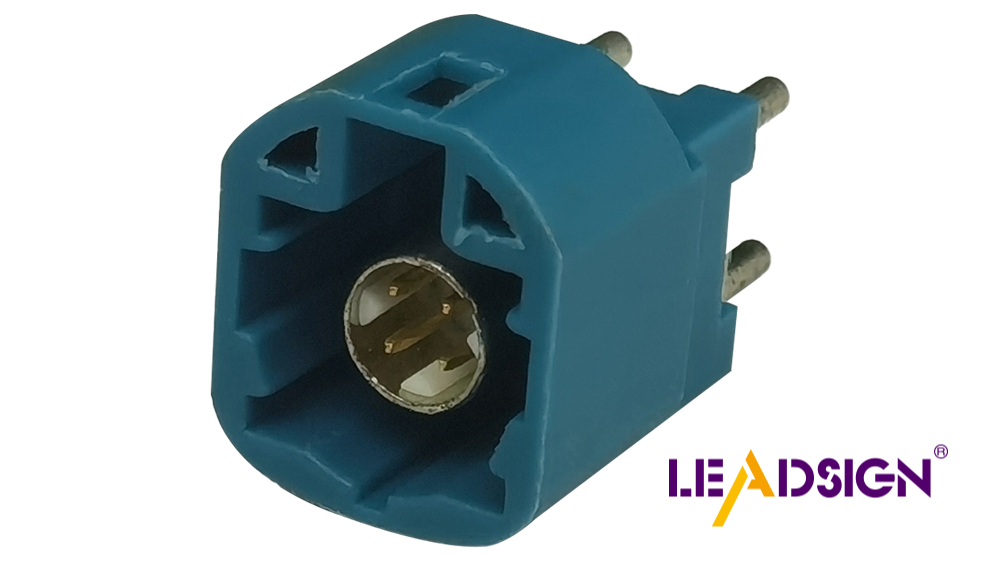

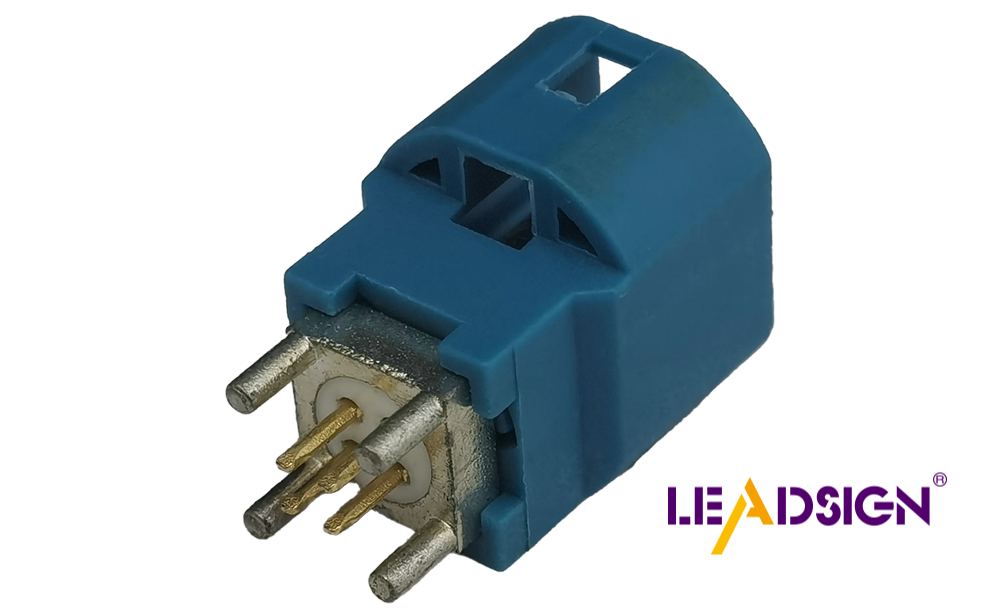

Understanding the Significance of Fakra Connectors in Contemporary Cars

Recognizing the Value of Fakra Connectors in Auto Sector

The Significance of FAKRA Connectors in Vehicle Uses

Uncovering the Advantages of Fakra Connectors in Automobiles