Understanding Automotive Electrical Connectors Types

Automotive electrical connectors are crucial in modern vehicles. They facilitate communication between various components, ensuring the car operates efficiently and safely. Poor-quality connectors can lead to failures, causing significant issues. Approximately 45% of high-voltage connector problems in vehicles stem from faulty connections. These connectors must withstand harsh conditions and maintain durability to prevent failures. Understanding the different automotive electrical connectors types is essential for maintaining vehicle safety and performance.

Basic Ideas of Automotive Electrical Connectors

What They Are and Why They're Important

Automotive electrical connectors link parts in a car's electrical system. They help electricity move smoothly, so the car works well.

How They Work in Cars

Connectors are key in car systems. They join wires and parts, letting electricity go where it needs to. Without them, the car's electrical system wouldn't work. They make sure each part gets the right power, keeping the car running well.

Why They're Important for Safety and Performance

Connectors are important for safety and how well cars work. Good connectors stop problems that could cause things to break. A bad connector might make brakes or lights not work. So, good connectors keep cars safe and working great.

General Features

Knowing about automotive electrical connectors helps pick the right ones for jobs. This includes what they're made of and how they're built.

What They're Made Of

The materials in connectors must handle tough conditions. They need to resist shaking, bumps, and rusting. Makers use metals like copper or brass because they conduct electricity well and last long. Coating these metals makes them even stronger against damage.

How They're Built

How connectors are made affects how they work. They must fit tight to stay connected. Many have locks to keep connections steady. The build should also make them easy to put in and fix. A good design lowers failure chances, helping the car stay reliable.

Scientific Research Findings: New studies show why predicting connector performance is vital. These studies stress strong materials and designs for tough car environments.

Types of Automotive Electrical Connectors

Knowing different types of automotive electrical connectors is key for cars to work well. These connectors have unique shapes and uses.

By How They Connect

Wire-to-Wire Connectors

Wire-to-wire connectors join two wires. This helps electricity move smoothly in a car's system. They often lock to stay connected, even if the car shakes.

Wire-to-Board Connectors

Wire-to-board connectors link wires to a circuit board. They help connect parts like sensors in a car. Using plug connectors made from strong materials keeps them lasting long.

By What They Do

Power Connectors

Power connectors send lots of electricity to important car parts. They use big pins for better contact, helping power flow well. Metals like copper are used because they conduct electricity great.

Signal connectors carry data between car parts. They're important for things like music systems and maps. High-speed link connectors send data fast so everything works on time. Signal connectors carry data between car parts. They're important for things like music systems and maps. High-speed link connectors send data fast so everything works on time.

By Their Design

Sealed Connectors

Sealed connectors keep connections safe from water and dirt. They're crucial in tough conditions to keep the car running right. Special greases can stop rust and wear.

Unsealed Connectors

Unsealed connectors are used where protection isn't needed much. They're easy to put in and fix, good for places needing quick access.

Features and Specifications

Electrical Specifications

Knowing the electrical details of car connectors is important. It helps cars work well and stay safe.

Voltage and Current Ratings

Car connectors need to handle certain power levels. They make sure systems get the right power without too much load. Makers build them to stop problems. For example, strong designs help in high-power places.

Resistance and conductivity

Resistance and conductivity are key for connector efficiency. Low resistance means less energy loss, so power moves well. High conductivity materials like copper improve performance. They keep connections stable, stopping overheating.

Mechanical Features

Mechanical features show how strong and easy to use car connectors are.

Durability and Longevity

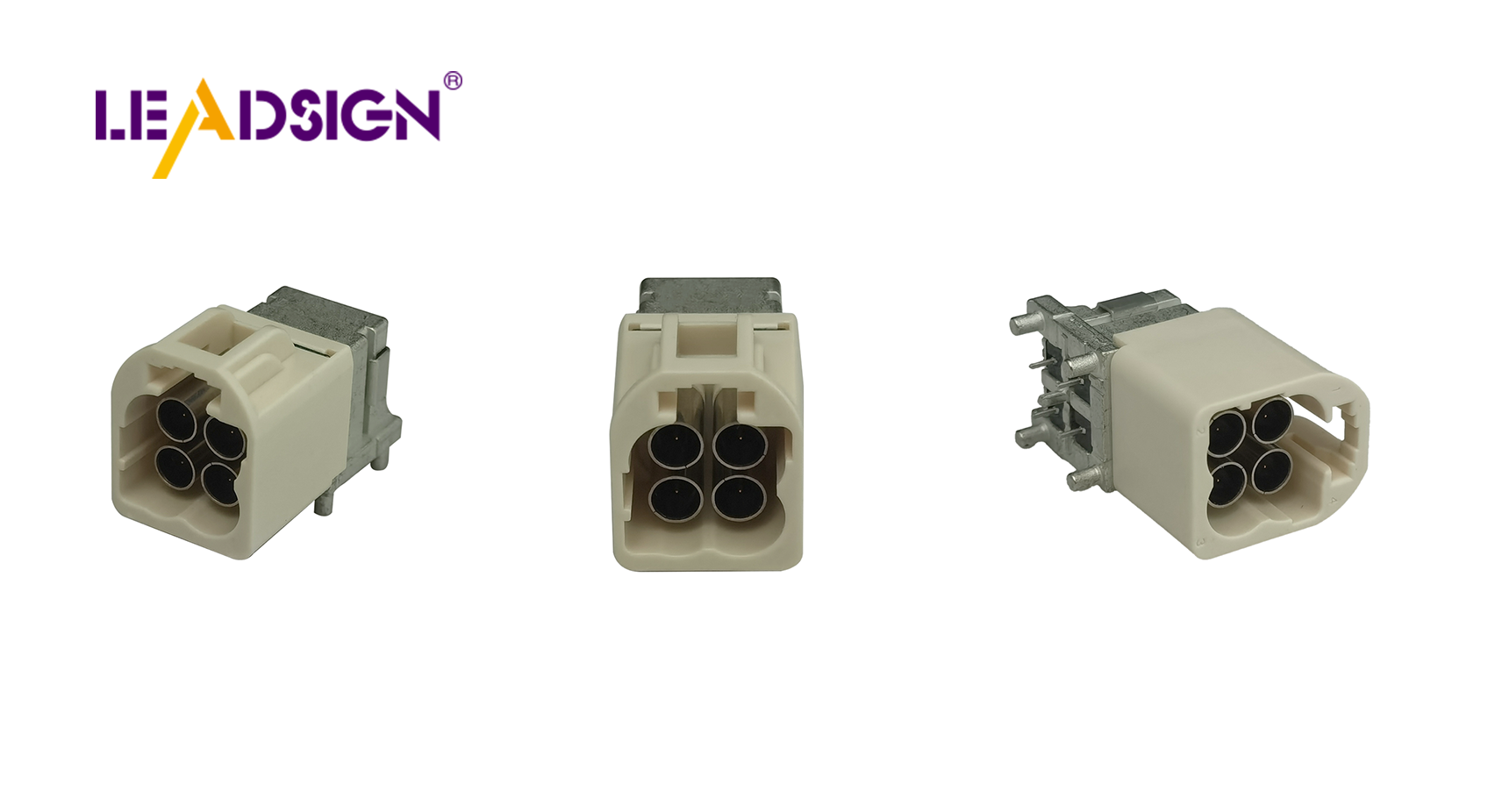

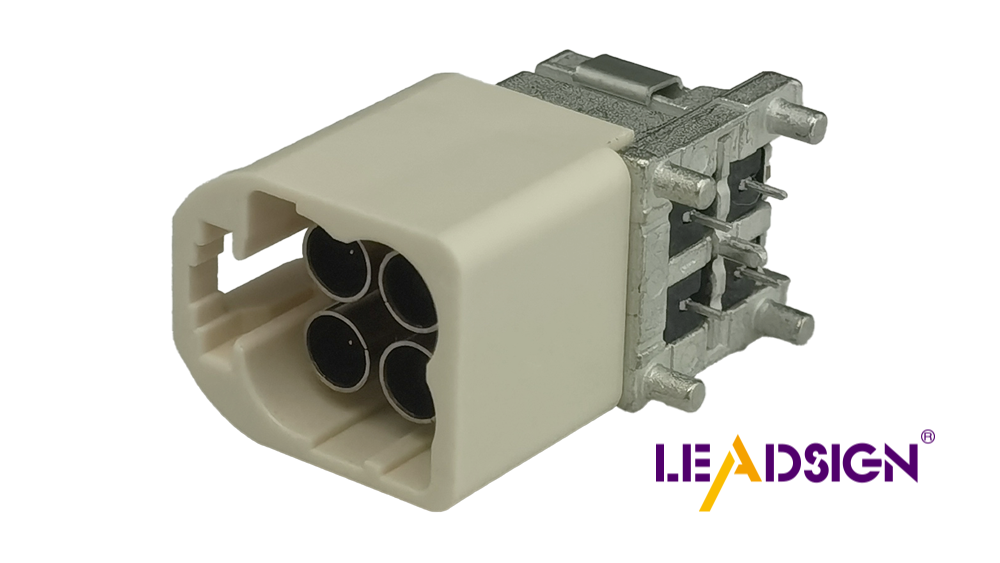

Durability matters in making connectors last long. They face tough conditions like heat changes and shaking. Strong plastics and metals help them last longer. The Connector Part for High-Demand Applications in the Automotive Sector shows why strong design is vital.

Ease of Installation and Maintenance

Easy installation is crucial for car work. Connectors should be simple to put in, saving time. Locking clips make it easier to connect securely. Easy-to-fix designs allow quick checks, reducing downtime.

Picking the Right Connector

Choosing the right car connector is very important. It helps the car work well and not break down.

Things to Think About

When picking connectors, think about a few key things.

Weather Conditions

Connectors need to handle different weather conditions. They face wetness, rust, and temperature changes. Designers should pick materials that fight these problems. For example, using grease on connectors can stop water and rust, making them last longer.

Matching with Car Systems

Connectors must fit with car systems. They should match the car's power needs. Using connectors with the right current stops overheating and keeps them working well. Designers must check that connectors fit perfectly in the car to avoid problems.

Mistakes to Avoid

Avoiding mistakes saves time and keeps the car's system working right.

Forgetting Specifications

A common mistake is forgetting connector specs. Each has certain voltage and current limits. Ignoring these can cause overheating or failures. It's important to pick connectors that meet power needs for safety.

Not Following Maker Rules

Not following maker rules can lead to bad installation and short life of connectors. Makers give clear instructions for setting up and care. Following these makes sure connectors work well and last long. Doing this lowers failure chances and boosts car reliability.

Understanding automotive electrical connectors is key for car safety. These connectors help parts talk to each other well. This stops problems from happening. When picking connectors, think about power levels and how many wires fit in a space. Good connectors make cars work better and easier to fix.

User Feedback: "Car electrical connectors are made for car systems. Think about power, wire size, and how they fit."

Picking the right connector helps your car run well with good wiring.

See Also

Exploring HSD Connectors in Automotive Sector

Navigating Ford Fakra Connections

Significance of Fakra Connectors in Contemporary Cars