Understanding Auto Wire Connector Types for Reliability

When it comes to automotive wiring connector types, selecting the right ones is crucial for your car's electrical system. These connectors play a vital role in ensuring the smooth operation and reliability of your vehicle. By understanding the various automotive wiring connector types available, you can make informed decisions to enhance the performance and safety of your car while driving.

Basics of Auto Wire Connectors

Definition and Purpose

What are Auto Wire Connectors?

Auto wire connectors join wires in cars. They keep connections tight and stable, helping car systems work well. These connectors have different shapes and sizes for specific uses in the car's electrical system.

Why are they essential in automotive systems?

Auto wire connectors keep your car's electrical system safe. They stop loose connections that can cause problems or dangers. Using the right connectors helps parts talk to each other, making your car work better and more reliably.

General Characteristics

Material Composition

Auto wire connectors use strong materials for tough car conditions. Good ones use copper or brass because they carry electricity well. These metals help power move easily. Many have coatings to stop rust and damage, lasting longer.

Design Features

Auto wire connector designs focus on being easy to use and strong. Some, like OEM Automotive Wire Connectors, fit easily with the car's original system. Others, like AVX 53-8702 Series IDC/Press-Fit WTB Connectors, handle tough conditions with strong connections. These features help them deal with shakes, heat, and hard conditions, making them last a long time.

Automotive Wiring Connector Types

Knowing about different automotive wiring connector types helps pick the right ones for your car. Each type has special features and uses, making them good for certain jobs in your car's electrical system.

Blade Connectors

Features and Applications

Blade connectors are flat metal pieces that fit into a slot. They are easy to use, which is why they are common in cars. These connectors make quick, safe links, perfect when you need to connect and disconnect wires often. You find blade connectors in fuse boxes and relay panels.

Pros and Cons

Pros:

Simple to attach and remove

Easy to find and cheap

Works for many uses

Cons:

Can get loose if not tight

Not great for places with lots of shaking

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end. They look like small tubes and need crimping to hold wires tight. These connectors make strong, lasting links between wires. You use them in car wiring harnesses where a solid connection is needed.

Pros and Cons

Pros:

Makes a strong link that lasts

Insulated ones stop water damage

Easy with the right tools

Cons:

Needs crimping tools to set up

Hard to take apart once joined

Ring and Spade Terminals

Features and Applications

Ring terminals form a full circle while spade terminals have an open end. Both connect wires to screws or studs easily. These are used for grounding or linking wires to battery ends.

Pros and Cons

Pros:

Stays connected well without falling off

Easy setup and removal

Comes in sizes for different screws or studs

Cons:

Needs tools for setup

Might need extra cover for safety

By knowing these automotive wiring connector types, you can choose better options that boost your car’s performance. Each type has its own good points and bad points, so think about what you need before picking connectors.

Quick Disconnects

Features and Applications

Quick disconnects let you join and unjoin wires easily. You don't need tools to use them. They have a male and female end that snap together. This is great for when you often need to connect or disconnect wires. You see quick disconnects in cars for speakers, lights, and parts needing regular care.

Quick disconnects come in many sizes and shapes. This helps you pick the right one for your needs. They mix power, signal, and other links well. This makes them useful in different automotive wiring connector types. Their design keeps connections safe but easy to take apart if needed.

Pros and Cons

Pros:

Ease of Use: Quick disconnects are fast to use without tools.

Versatility: They come in many sizes for different uses.

Signal Integrity: They keep signals steady even with interference.

Cons:

Potential for Wear: Using them a lot can wear them out over time.

Limited Load Capacity: Not good for high power as they can't handle big loads well.

Knowing these features helps pick the best connectors. Quick disconnects are handy for many car uses, giving ease and trustworthiness.

Factors Influencing Connector Reliability

Knowing what makes connectors reliable helps you pick the best ones for your car. Let's look at the main things that affect how reliable automotive wiring connector types are.

Quality of Materials

Importance of High-Quality Materials

Good materials make connectors work well. Look for connectors made from strong metals like copper or brass. These metals carry electricity well, lowering the chance of overheating or breaking.

Impact on Performance

Using great materials affects performance directly. Connectors with better materials last longer and keep connections steady. This steadiness boosts your car's electrical system reliability.

Environmental Considerations

Temperature Resistance

Connectors need to handle extreme temperatures. You want connectors that work in both hot and cold without failing. This ability ensures your car runs smoothly in different weather.

Moisture and Corrosion Resistance

Moisture and rust can harm connectors. Pick connectors with coatings to stop rust and damage. This protection keeps connections safe and makes automotive wiring connector types last longer.

Compatibility with Automotive Systems

Electrical Compatibility

Electrical compatibility is key. Make sure connectors match your car's voltage and current needs. This fit stops electrical problems and keeps power flowing well.

Mechanical Compatibility

Mechanical compatibility means fitting connectors right in the vehicle. Choose connectors that fit the car's design properly. Good fitment prevents loose connections, boosting reliability.

Automotive Testing Experts say that connectors face tough conditions even before a car is built. This toughness is crucial for keeping dependable connections during tests.

By focusing on these points, you can choose the automotive wiring connector types that fit your needs best. Reliable connectors help keep your vehicle safe and performing well.

Picking the Right Connectors

Choosing connectors for your car needs careful thought. You need to know what your car needs and check the technical details. This keeps your car's electrical system safe and working well. Choosing connectors for your car

Checking What You Need

Power Needs

First, find out how much power your car uses. Connectors must handle this power without getting too hot. This stops problems and keeps things running smoothly. Always make sure the connector can handle your car's power needs.

Weather Conditions

Think about where the connectors will be used. They should work in hot, cold, wet, or shaky places. OEM Automotive Connectors are made from strong stuff to last in tough spots, keeping them from breaking down.

Looking at Connector Details

Maker Rules

Find connectors that follow good maker rules. These rules show they were tested well to work on bumpy roads without losing their grip.

Safety Checks

Safety checks are important. They show that connectors meet safety rules and work well. Certified ones keep signals steady and help your car stay safe and run right.

A study on Automotive Testing shows testing is key for good performance. Connectors must last long even when tested hard.

By thinking about these things, you pick connectors that make your car better and more reliable.

Understanding auto wire connector types is important for your car's reliability. You learned about connectors like blade, butt, ring, and quick disconnects. Each has special features and uses. Good materials and weather resistance are key for picking reliable connectors.

Survey Results: Car testing shows it's vital to pick connectors that meet OEM standards.

Think about power needs and weather conditions. This helps you choose the right ones. Pick connectors that boost your car’s performance and safety for a smooth drive. pick connectors that boost

See Also

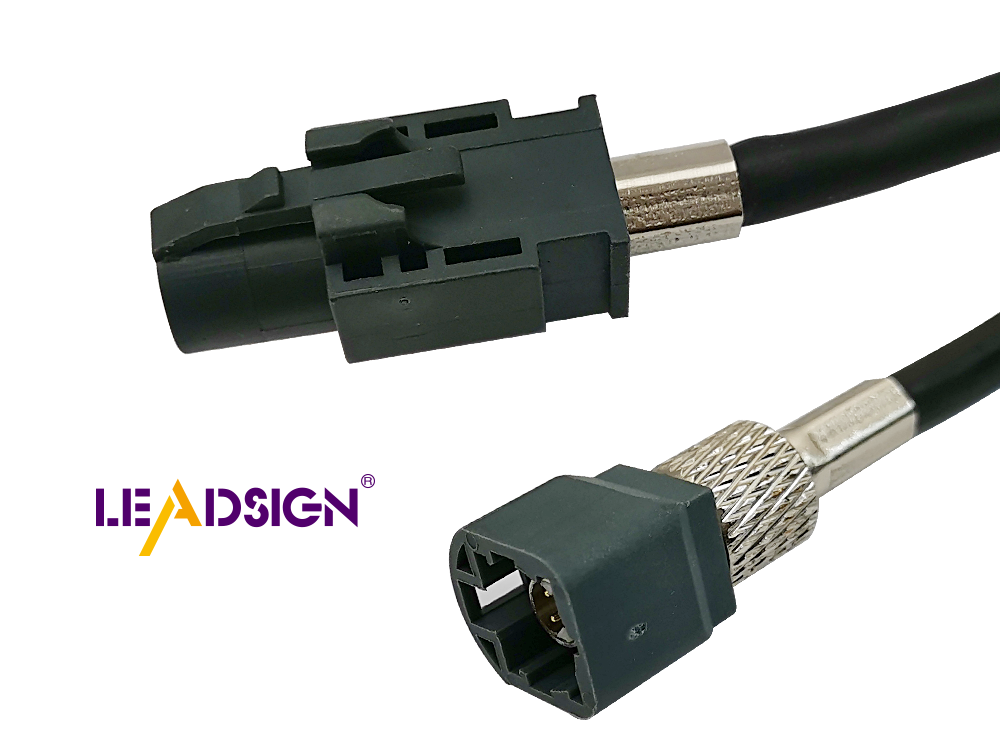

Exploring HSD Connectors in Automotive Technology

Significance of HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Tech

Significance of Fakra Connectors in Auto Sector

Enhancing Auto Data Transfer: Advanced Connectors and Cables