The Ultimate Guide to Automotive Wiring Connector Types

Automotive wiring connector types are crucial components in a car's electrical system. These connectors play a vital role in ensuring proper connections between various parts, which is essential for the smooth operation of the vehicle. The market for automotive wiring connector types is rapidly expanding, with a value of $17 billion in 2021. It is projected to grow by 5.8% annually until 2026, highlighting their significance in modern vehicles. Understanding the different automotive wiring connector types is key to appreciating their role in enhancing the performance and safety of cars.

What are Wiring Connectors?

Definition and Purpose

Wiring connectors are key parts in cars. They link electronic parts so power and signals move well. Think of them as your car's electrical lifeline. Their main job is to spread power among electronic parts. Made from strong stuff, they handle tough conditions like heat changes, wear, and dirt.

Importance in Automotive Systems

In cars, wiring connectors are very important. They help ECUs, sensors, and actuators talk to each other. This makes things like engine control, lights, climate control, and navigation work well. Without good connectors, these systems might not work right and could be unsafe.

Basic Components of a Connector

Knowing connector parts helps you see why they matter.

Contacts

Contacts are the main part of a connector. They are metal pieces that make the electrical link. Good contacts send power and signals well. The metal used matters for good conductivity and rust resistance. Gold-plated contacts are best for high-performance because they conduct well and last long.

Insulation

Insulation is also important. It covers contacts to stop shorts and protect from outside stuff. Fully insulated quick disconnects make wire setups easier without soldering.

Housing

The housing is the outer cover holding it all together. It supports and protects contacts and insulation. In car connectors, housing must be tough for harsh car conditions like moisture or extreme temperatures. A strong housing keeps the connector working well over time.

By knowing these parts, you learn how connectors help your car run safely.

Types of Automotive Wiring Connectors

Knowing different automotive wiring connector types helps you choose wisely for your car's electrical system. Each type has special traits, uses, pros, and cons. Let's look at some common ones.

Blade Connectors

Features and Applications

Blade connectors, or spade connectors, are flat metal pieces that fit into slots. They're used in cars because they're easy to use. They link wires to things like speakers and lights. Their design lets you connect and disconnect quickly, which is good if you need to change parts often.

Advantages and Disadvantages

Blade connectors have many benefits. They make strong links and are simple to set up without tools. But they might get loose over time, especially where there are vibrations. This can cause bad connections that affect how devices work.

Ring and Spade Terminals

Features and Applications

Ring and spade terminals are also popular in cars. Ring ends fit over bolts or screws; spade ends slide under screw heads. They're used for grounding and battery links.

Advantages and Disadvantages

Ring and spade terminals are reliable once tightened well. They stay put even with lots of shaking, but you need tools to install or remove them, which is a hassle if changes happen often.

Butt Connectors

Features and Applications

Butt connectors join two wire ends together in a line. They're tube-shaped and need crimping to hold wires tight. You use them in cars to fix or extend wire groups because they create solid links.

Advantages and Disadvantages

Butt connectors give strong connections that resist water or shaking damage. They're easy with the right tool but hard to undo once crimped, which is tricky if rewiring is needed.

In cars, picking the right automotive wiring connector types depends on what the job needs. For example, fiber optic segments are becoming more popular than regular wire segments for fast data transfer needs. Also, automotive HSD connectors are chosen for high-speed data tasks like infotainment systems instead of normal wire-to-wire ones.

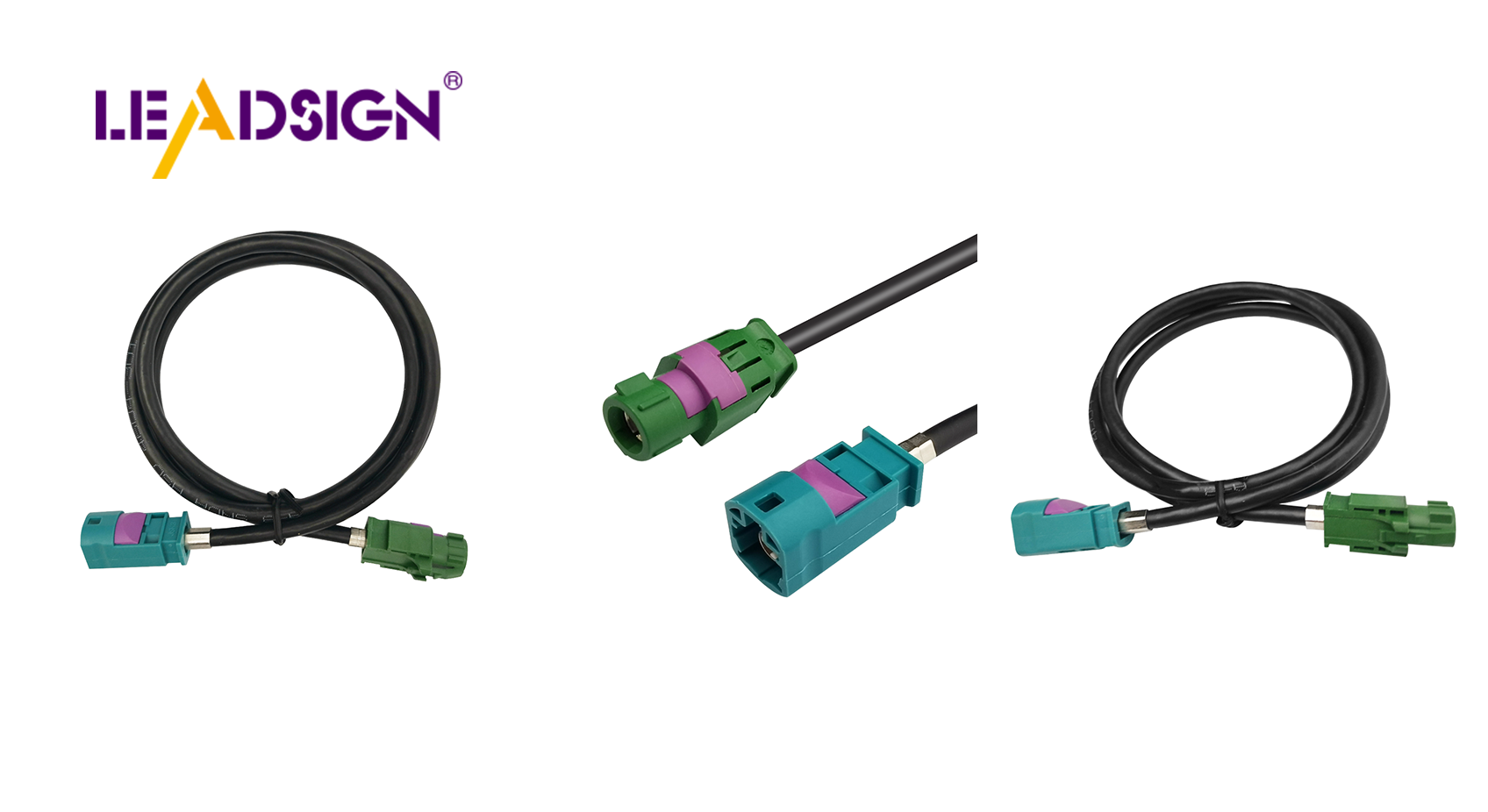

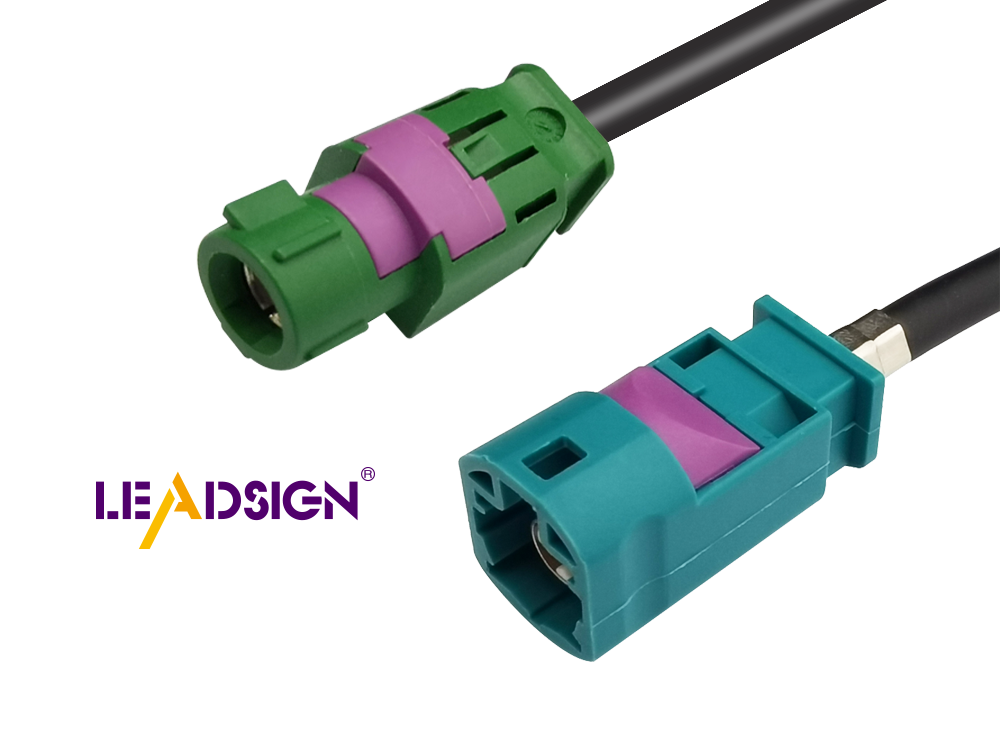

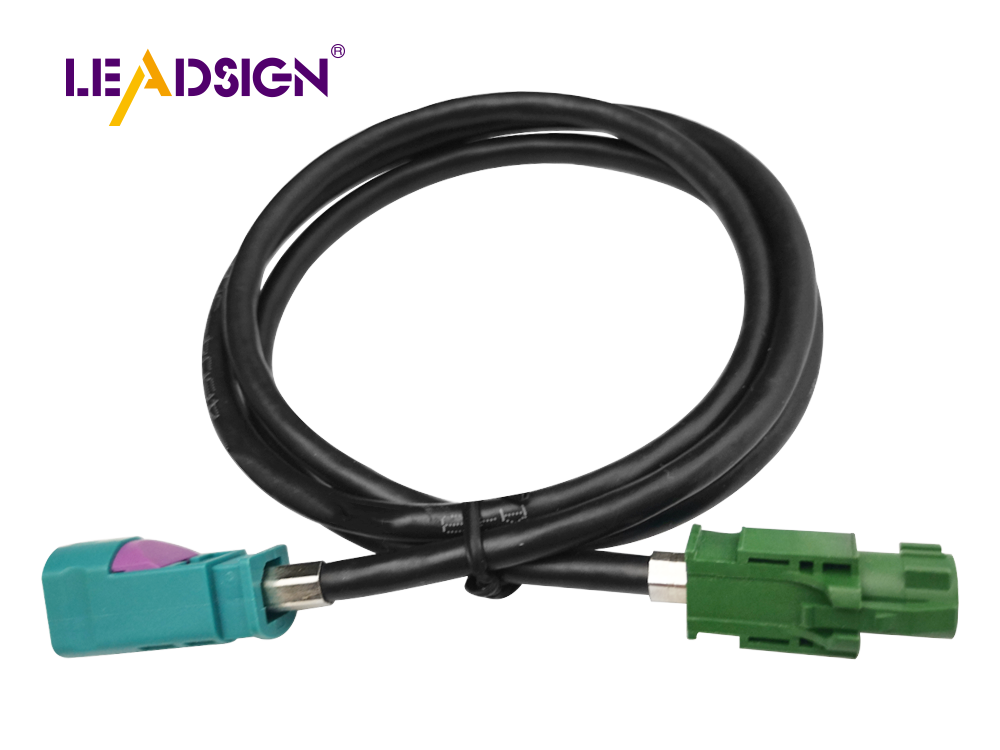

High-Speed Data (HSD) Connectors

High-Speed Data (HSD) connectors are a big step forward in car wiring. They help with fast data transfer, which is needed as cars get more techy. These connectors make sure electronic parts talk to each other quickly and well.

Features and Uses

HSD connectors have cool features for fast data use. They include:

Primary and Secondary Lock: Keeps connections tight so they don't come apart.

Crimp Connection: Holds wires strong, making them last longer.

High Cable Retention Force: Stops cables from moving out of place.

High Coding Efficiency: Different codes stop wrong connections.

You see HSD connectors in places like:

Car electronics, helping sensors and control units talk.

Telecoms, like radio stations, for quick data moves.

Infotainment systems, linking audio and video smoothly.

USB links, Ethernet, and other digital networks.

Good Things and Bad Things

HSD connectors have many good points over old types:

Good Points:

Fast data move is key for new car systems.

Strong build means less fixing needed later.

Coding system helps avoid wrong links.

Bad Points:

HSD might cost more than simple wire ones because they're fancy.

Setting them up might need special tools or skills.

As car wiring changes, HSD connectors shine by handling fast data needs. As cars add more smart gadgets, these connectors will be even more important. Knowing about them helps you pick the best for your car's electric setup.

Picking the Right Connector

Choosing the right car wiring connector is important. It helps your car's electrical system work well and stay safe.

Things to Think About

Electrical Needs

First, check what your system needs electrically. Find out how much power it uses. Make sure the connector can handle this power. Check the voltage too, so it matches your system to avoid problems. The number of contacts should fit how many wires you have.

Weather Conditions

Next, think about where the connectors will be used. Will they face rain, heat, or rust? These things matter when picking connectors for tough places. Choose ones that can handle these conditions to keep connections strong.

Fit with Current Systems

Make sure they fit with what you already have. Connectors should match your setup easily. This includes how they connect, which affects how easy they are to install and use well. Look at what they're made of for good power flow and no rust.

Quality and Rules

When picking car wiring connectors, quality and rules are key.

Industry Rules

Follow industry rules so connectors are safe and work well. These rules guide making and testing connectors under different situations. Know these rules to choose wisely.

Quality Checks

Quality checks make sure connectors last long and work right. Pick from trusted makers who do strict quality tests. This means fewer fixes needed later on.

By thinking about these things, you can pick the best car wiring connectors for your vehicle. This choice makes your car's electrical system better and safer, giving you peace as you drive.

Practical Tips for Installation and Maintenance

Installation Best Practices

Installing automotive wiring connectors right makes them last longer. Here are some tips:

Tools Needed

Get these tools before starting:

Wire cutters

Crimp tool

Heat gun or lighter (for shrinking tubes)

Multimeter (to test connections)

Screwdrivers and pliers

These tools help make the job easier.

Step-by-Step Guide

Prepare Wires: Cut off the wire cover at the ends. Show enough wire to connect well but not too much to avoid shorts.

Pick the Right Connector: Choose one that fits your wire size and use. This makes sure it connects well.

Crimp Connector: Put the bare wire in the connector and crimp it tight with a tool. This keeps it in place and helps electricity flow.

Use Heat Shrink Tubing: Slide tubing over the join, then heat it to shrink. It protects from water and rust.

Test Connection: Use a multimeter to check if it's connected right. This finds problems before you finish.

Follow these steps for a strong connection in your car's system.

Maintenance and Troubleshooting

Regular checks stop problems and keep connectors working longer.

Common Problems

Connectors can have issues like:

Rusting: Water and dirt can cause rust, making bad links.

Loose Links: Shaking can loosen them over time.

Wear Out: Using them a lot wears them down, hurting how they work.

Fixes and Prevention

Try these fixes:

Regular Checks: Look at connectors often for wear or damage signs. Find problems early to stop bigger ones later.

Clean Well: Use cleaner to remove dirt or rust, then add grease for protection against water.

Tighten Links: Make sure they're tight using ties or clamps to cut down on movement.

Upgrade When Needed: As tech gets better, think about stronger connectors like smart ones or fiber optics. They offer better safety and work well.

By doing this maintenance, your car's wiring stays in good shape, helping systems run safely.

Picking the right car wiring connector is important for your car's safety. Knowing different types helps you choose what you need. Look at connectors and think about power needs and weather conditions. Dr. Arjun Patel says High-Speed Data connectors are popular because of new tech. This shows why staying informed matters. For more help, ask experts or do more research to make the best choices for your car systems.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Mastering HSD Connectors: A Detailed Overview

Essential HSD Connector Knowledge for Automotive Professionals

Significance of Modern Vehicles' Fakra Automotive Connectors