The Ultimate Guide to Automotive Wire Connector Types

Automotive wire connectors are crucial for your car's electrical systems, ensuring that components connect and function efficiently. Understanding the different automotive wire connectors types is essential for selecting the right one for each application. High heat can significantly increase the risk of failures. Poor solder or crimp connections often fail due to vibrations or corrosion. Being aware of these factors helps you make informed choices, maintaining the safety and reliability of your car's electrical system.

Overview of Automotive Wire Connectors

Definition and Function

What are Wire Connectors?

Wire connectors join wires in cars. They help signals and power move between parts. This makes sure your car's electronics work well, like the engine and radio.

Importance in Automotive Systems

Wire connectors are key in cars. They keep electrical links strong so your car runs smoothly. Bad connectors can cause problems or be unsafe. Picking the right type helps your car last longer.

Common Materials Used

Plastic Connectors

Plastic connectors are common in cars. They have benefits:

Lightweight: They make cars lighter, saving fuel.

Corrosion Resistance: Plastic doesn’t rust, good for wet places.

Cost-Effective: Usually cheaper than metal ones.

But plastic may not handle heat well. Think about where you use them.

Metal Connectors

Metal connectors are tough and strong. They're used where it's hot or stressful. Benefits include:

High Temperature Resistance: Good for hot areas like engines.

Robustness: Strong even in tough spots.

Electrical Conductivity: Great for sending power efficiently.

Metal is durable but can rust if not sealed well. Keep them dry to avoid rusting.

Types of Automotive Wire Connectors

Knowing different automotive wire connectors is important. It helps your car's electrical parts work well. Each type has special uses. Pick the right one for your needs.

Crimp Connectors

Crimp connectors are very common in cars. They hold wires tight by squeezing them together.

Types of Crimp Connectors

Butt Connectors: Join two wires end-to-end, good for longer wires.

Ring Terminals: Attach wires to screws or bolts securely.

Spade Terminals: Easy to connect and disconnect, great for frequent changes.

Advantages and Disadvantages

Crimp connectors have many benefits:

Speed: Quick to install without heat or solder.

Reliability: Strong seal keeps out air and water, less risk of failure.

But you need the right tools to crimp correctly. Bad crimping can cause weak connections.

Solder Connectors

Solder connectors use melted metal to join wires and connectors. This is another popular choice in cars.

Types of Solder Connectors

Solder Sleeves: Mix solder with heat-shrink tubing for a waterproof seal.

Solder Lugs: Used for tough jobs, giving a strong connection.

Advantages and Disadvantages

Solder connectors have clear benefits:

Strength: Solid bond that handles vibrations well.

Conductivity: Great for sending power efficiently.

But soldering takes time and skill. High heat can harm delicate parts.

Push-On Connectors

Push-on connectors are easy to use, also called quick-disconnects. They are handy in cars.

Types of Push-On Connectors

Male and Female Disconnects: Fit together easily for fast connections.

Bullet Connectors: Secure fit with bullet-shaped ends that match sockets.

Advantages and Disadvantages

Push-on connectors are convenient:

Ease of Use: No tools needed to connect or disconnect.

Versatility: Good for many uses like lights or audio systems.

However, they might not be as secure as crimp or solder ones in shaky places.

By learning about these types, you can choose wisely to keep your car's electrical system safe and reliable.

Special Connectors

Special connectors are important for car electrical systems. They work well in tough spots. These connectors resist water and heat. Knowing about them helps you pick the right one.

Waterproof Connectors

Waterproof connectors keep water away from wires. This stops rust and breaks. You see them where it's wet, like under the hood.

Sealing Mechanism: They use seals to block water. This keeps connections dry.

Applications: Good for lights outside or engine parts.

Advantages: They stop rust and shorts by keeping out moisture.

Using waterproof connectors protects your car's wires from water problems.

High-Temperature Connectors

High-temperature connectors handle a lot of heat. They're used near engines where it gets hot.

Material Composition: Made from heat-proof stuff like metal or special plastic.

Applications: Found in engine systems and hot areas.

Advantages: They stay strong in heat, stopping connector issues.

Picking high-temperature connectors helps your car's wires work safely when it's hot.

Picking the Best Connector

Choosing the right connector for your car's electric system is important. Think about many things to make sure the automotive wire connectors you pick work well and keep your car running smoothly.

Things to Think About

Power Needs

First, check what power your project needs. Look at how much electricity will go through the connector. For strong power needs, choose connectors that handle lots of electricity without getting too hot. 4 way waterproof connectors are great for strong and safe connections, especially where it's wet.

Weather Conditions

Weather affects which connector is best. If it might get wet or very hot, pick connectors made for those places. Waterproof connectors, like SuperSeal, keep water out, so they're good in wet spots. Hot areas need high-temperature connectors to stay safe near engines.

Mistakes to Avoid

Forgetting Compatibility

A big mistake is not checking if connectors fit with wires or parts they join. Make sure the automotive wire connectors match the wire size and cover material. Wrong matches can cause bad links and problems.

Ignoring Quality Rules

Skipping quality checks can hurt your car’s electric system safety and work. Always pick connectors that meet rules and have certificates. Good ones from trusted brands like Tyco/Amp last long and work well. Don’t use cheap ones; they might break easily.

By thinking about these points and avoiding mistakes, you can choose the right automotive wire connectors for your car. This keeps your electric system safe and working well, making your car better overall.

Installation Techniques

Installing automotive wire connectors right keeps connections strong. Use the correct tools and methods. Let's look at what you need and how to do it step-by-step.

Tools Needed

To put in wire connectors well, use special tools. These help make sure connections are safe and last long.

Crimping Tools

Crimping tools are key for crimp connectors. They squeeze the connector onto the wire tightly. Pick a tool that fits your connector type. A good crimping tool makes a strong link, lowering failure chances.

Soldering Tools

Soldering tools are needed for solder connectors. You use a soldering iron to melt solder and join wires to connectors. A station with adjustable heat is best. It lets you control temperature, avoiding harm to fragile parts.

Step-by-Step Guide

Follow these steps to install wire connectors right. Doing this improves your car's electrical system's safety and work.

Getting the Wire Ready

Strip the Wire: Take off insulation from the wire end with a stripper. Show enough wire for the connector but not too much.

Check the Wire: Look at exposed wire for damage or fraying. Bad wires can cause weak links and need trimming or changing.

Twist Strands: If stranded, twist strands together. This helps fit into the connector better and makes a solid link.

Connecting the Connector

Put in the Wire: Insert prepared wire into connector snugly, reaching proper depth inside.

Crimp or Solder:

For crimp connectors, use tool to press connector onto wire firmly.

For solder connectors, heat iron and apply solder fully over joint.

Check Connection: Look for gaps or loose wires in connection; it should be tight without defects.

Test Connection: Use multimeter to check if connection works safely and properly.

By using these steps with right tools, you can install automotive wire connectors well, keeping your car's electric system reliable and efficient.

Choosing the right wire connector is key for your car's electrical system. It keeps things safe and reliable. Knowing different types helps you decide better. Use this knowledge to improve your car.

Crimping joins a contact to a wire by squeezing them together. You need a crimping tool for this. The tool's handles are pressed to make a strong link between the contact and wire.

To learn more, ask experts or find other resources. Your car's electrical health relies on it.

See Also

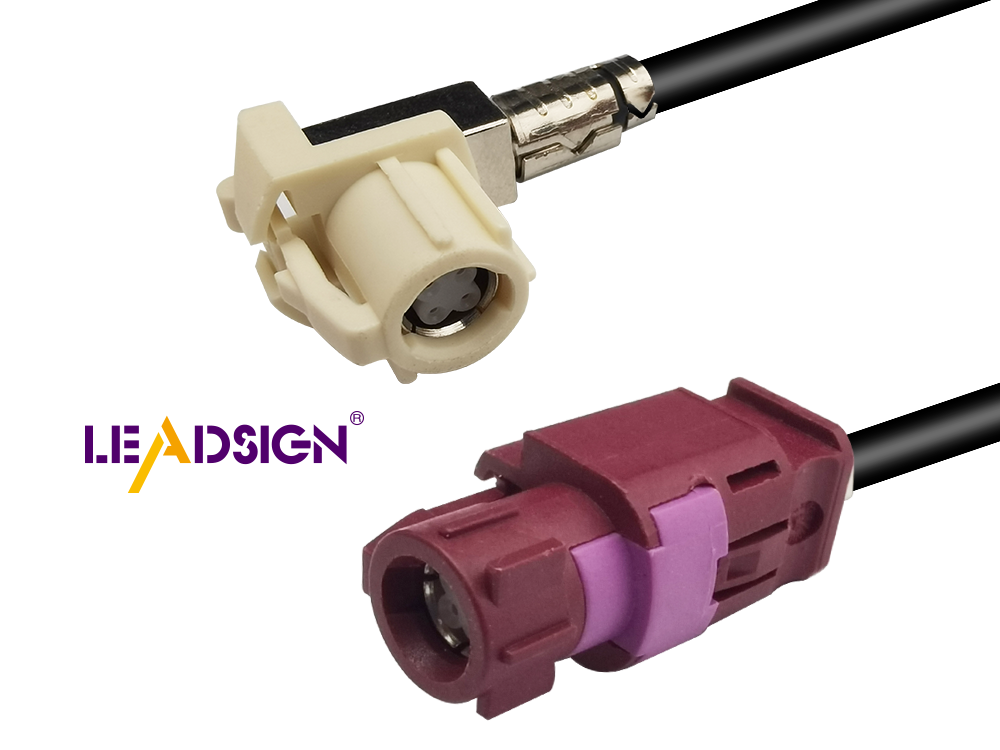

Exploring Ford Fakra Connectors: A Comprehensive Overview

Essential HSD Connectors in Automotive: An Introductory Overview

In-Depth Look at Fakra Connectors: Benefits, Uses, and Setup Advice