Types of Wire Connectors in Automotive Applications

Automotive electrical connectors types are crucial in vehicles, ensuring the efficient operation of your car's electrical systems. These connectors link various components, allowing electricity to flow where it's needed. There are numerous types of automotive electrical connectors, each designed for a specific function. These connectors maintain the proper functioning of your car's electrical system. Understanding them provides insight into the complexity and efficiency of modern vehicles.

Types of Wire Connectors

Knowing different car wire connectors helps keep your car working. Each type has a special job for safe connections.

Crimp Connectors

Characteristics and Uses

Crimp connectors are simple and strong. They join wires by squeezing a metal piece around them. This makes a tough link. They work well where shaking might loosen other links. Crimp connectors are used in cars because they handle rough conditions well.

Installation Techniques

To use crimp connectors, you need a special tool. First, take off the wire cover. Put the wire in the connector. Squeeze it with the tool to hold tight. Make sure it's snug to stop loose links. Doing it right means it will last long.

Solder Connectors

Characteristics and Uses

Solder connectors make a lasting link by melting solder on wires. They conduct electricity well and resist weather changes. You see them where strong links are needed in cars. They don't rust easily, so they're good for many uses.

Installation Techniques

To use solder connectors, you need a hot iron and solder metal. Start by removing the wire cover. Twist wires together, heat them with the iron, then add solder until it covers all parts. Let it cool to harden into one piece for a solid link.

Push-On Connectors

Characteristics and Uses

Push-on connectors are easy to use without tools. You can connect or disconnect fast when needed often. They fit tightly and are common in cars for being handy and effective.

Installation Techniques

For push-on connectors, just remove the wire cover first. Push the wire into place until it clicks locked in place securely without extra tools needed.

Specialty Connectors

Specialty connectors are very important in cars. They have special features for certain needs. Knowing about them helps you choose the right ones for your car.

Multi-Pin Sealed Connectors

Multi-pin sealed connectors are special. They keep out dirt and water. You find them where it's wet or dusty. These connectors keep your car working well, even in tough places.

To use them, line up the pins first. Push the connector until it clicks. This makes sure it's tight and safe from outside stuff. Check them often to keep things running smoothly.

Heat Shrink Connectors

Heat shrink connectors protect against water and other things. They're used where wires might get wet.

Start by taking off wire covers. Put wires in the connector, then heat it with a gun. The heat makes it shrink tight around wires, keeping them safe from shorts and rusting. Check these often to make sure they stay good.

By learning about these connectors, you understand more about how car wiring works well.

Makers and Rules

Knowing who makes car connectors and the rules helps you choose well. This part talks about top makers and rules that keep things good.

Top Makers

Main Companies

Some companies are big in making car connectors. TE Connectivity, Delphi Technologies, and Molex are leaders. They make many types for different car needs. These companies care about making strong and new products that work well in tough car places.

New Ideas in Connectors

Top makers always try to make better connectors. They create ones that last longer, work better, and are easy to use. Some have made connectors that stop water and dirt from getting in. Others make ones for fast data sharing, important for cars with cool tech stuff. By being smart with new ideas, these makers meet what cars need today.

Rules for Connectors

Why Rules Matter

Rules are super important for car connectors. They make sure connectors are safe and work right. When makers follow rules, their stuff is safe to use with other parts in a car's system. Rules also help trade by letting different brands fit together easily.

Common Connector Rules

Many rules guide car connectors. ISO and SAE set lots of them up. Some common ones are ISO 19642 for connector basics, and SAE J2030 for tough-use connectors. Knowing these rules helps you pick the right connector for your car.

Installation and Maintenance

Installing and taking care of automotive electrical connectors types keeps your car's wires working well. By doing things the right way, you can stop problems and keep your car running great.

Best Practices for Installation

Tools and Equipment

To put in automotive electrical connectors types, get the right tools. You need:

Wire strippers to take off wire covers.

Crimping tools to hold crimp connectors tight.

Soldering iron and solder for joining with solder connectors.

Heat gun for shrinking heat shrink connectors.

Multimeter to check if connections work.

Having these tools ready makes putting in connectors easier.

Step-by-Step Guide

Prepare the Wires: Take off the wire cover ends. Make sure the wire is clean and not broken.

Select the Connector: Pick the right connector type for what you need. Think about where it will be used and how much power it needs.

Attach the Connector:

For crimp connectors, put wire in, then squeeze with a tool.

For solder connectors, twist wires, heat them, then add solder until covered.

For push-on connectors, push wire in until it clicks locked.

For heat shrink connectors, put wire in, heat it so it shrinks around.

Test the Connection: Use a multimeter to test connection. Make sure it's strong without resistance.

Secure the Wiring: Use ties or clamps to keep wires neat and still.

Maintenance Tips

Regular Inspection

Check your automotive electrical connectors types often to make sure they are okay. Look for wear or rust signs. Ensure all parts are tight and safe. Regular checks help find problems early before they get bigger.

Troubleshooting Common Issues

If there are issues with your automotive electrical connectors types, try these steps:

Loose Connections: Tighten loose parts so they stay locked in place.

Corrosion: Clean rusty parts with a brush or cleaner. Use grease to stop more rust later.

Broken Wires: Change any bad wires with new ones that fit right.

Faulty Connectors: Replace damaged parts with same size ones to keep them working well together.

By following these tips for installing and maintaining, you can make sure your car's electric system stays strong and works well.

Picking the right wire connectors is important for your car. Each type has a special job to keep things safe and working well. As cars get better, new connectors work even better and last longer. Knowing about these changes helps you choose wisely. Follow industry rules to make sure everything fits and works right. By knowing and picking the right connectors, you help your car work better and last longer. Keep learning about new connector ideas to keep your car in good shape.

See Also

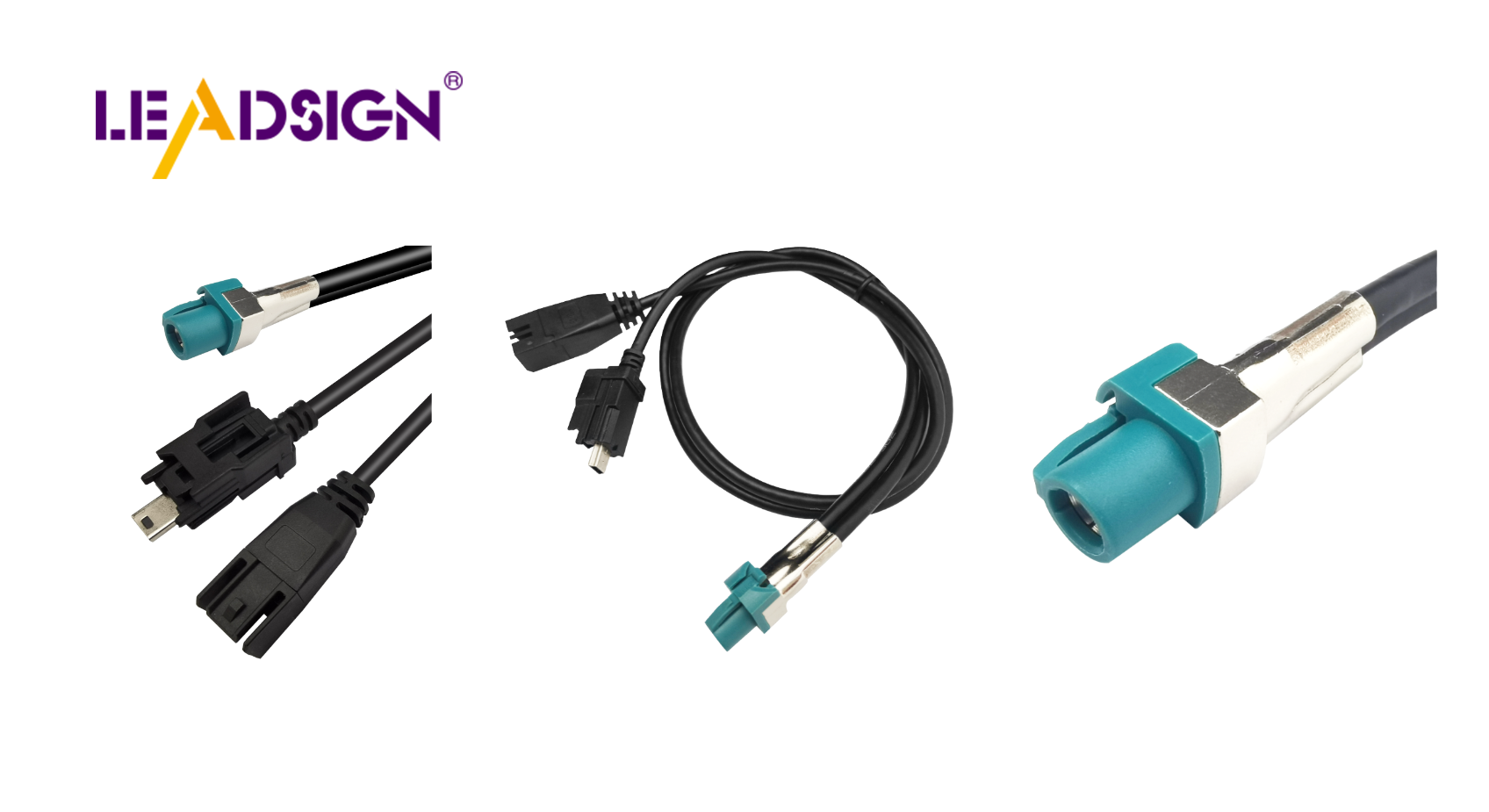

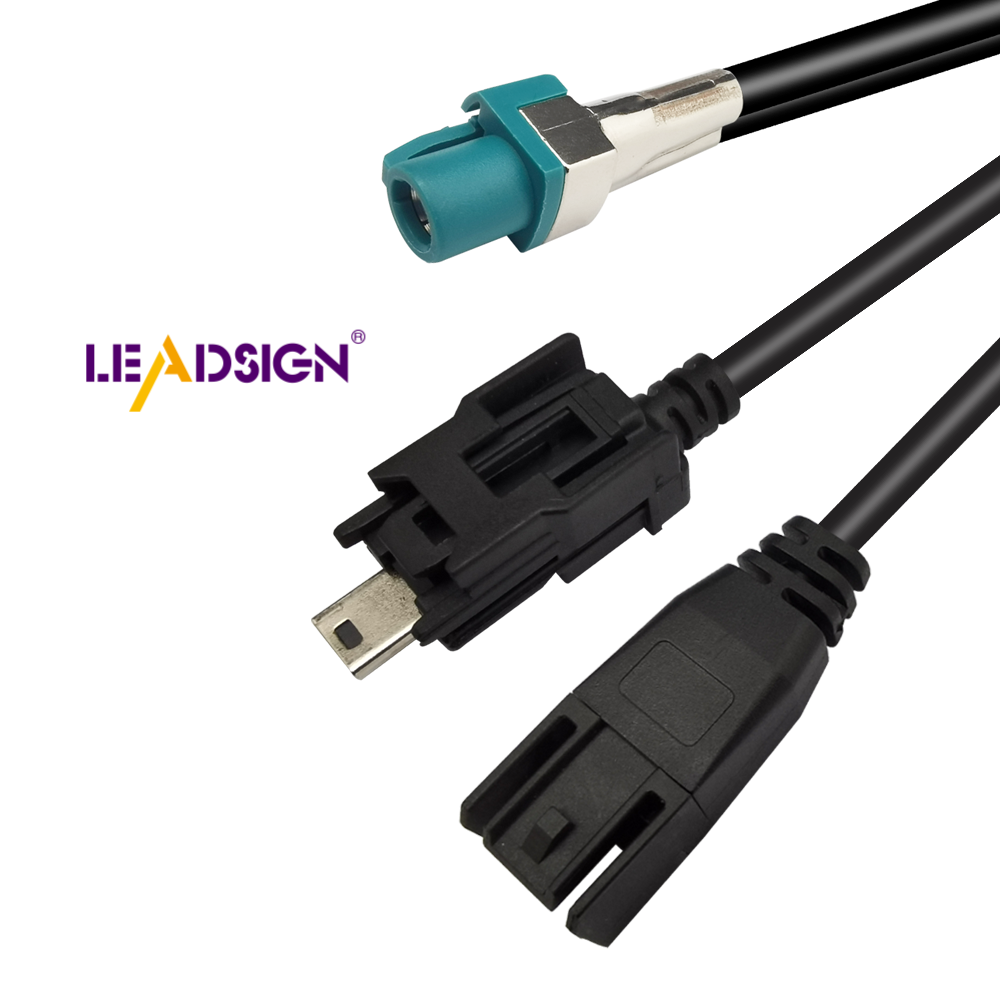

Essential Guide to HSD Connectors in Auto Sector

Benefits of HFM Connectors for Auto Applications

Significance of FAKRA Connectors in Auto Uses