Types of Wire Connectors in Automotive Applications

Automotive electrical connectors types are crucial components in cars. They play a vital role in ensuring the proper functioning of car systems. With the advancement of technologies such as ADAS and infotainment, the demand for robust automotive electrical connectors types is increasing. These connectors are essential for the operation of safety systems like airbags and brakes, enhancing the protection of both vehicles and occupants. Understanding the various automotive electrical connectors types is essential for maintaining the safety and optimal performance of vehicles.

Basics of Wire Connectors

What are Wire Connectors?

Wire connectors are important in cars. They connect wires, making sure they stay together. There are different kinds like wire-to-wire and wire-to-board. Each type is used for different jobs in a car's system. For example, wire-to-wire connectors help electric cars manage energy well.

Why are they Important in Cars?

In cars, wire connectors do important work. They help new tech like ADAS and infotainment systems run smoothly. By keeping connections strong, they make cars safer and work better. They also let many signals pass through one connector, which is needed for complex car systems.

Main Parts

Conductors

Conductors are the main part of wire connectors. They move electricity between car parts. Good conductors keep energy flowing without losing power. In cars, conductors must handle tough conditions like heat and shaking.

Insulation

Insulation covers conductors to stop shocks and short circuits. It keeps water and dirt away from the connection too. In cars, insulation needs to be strong against weather to last long.

Terminals

Terminals link conductors to other car parts. They come in shapes like spades or bullets. Terminals need to fit tight so they don't come loose. In cars, they often have extra locks for safety and steadiness.

Types of Automotive Wire Connectors

Automotive electrical connectors types are key for car systems to work well. Different connectors have special uses. Knowing them helps pick the right one.

Crimp Connectors

Crimp connectors are popular in cars because they are easy and reliable. They hold wires tight by squeezing them together.

Types of Crimp Connectors

Butt Connectors: Join two wires end-to-end, often for permanent links.

Ring Terminals: Attach wires to a bolt or screw, giving a strong hold.

Spade Terminals: Simple to put on and take off, good for frequent changes.

Advantages and Disadvantages

Advantages:

Easy setup with few tools.

Strong and dependable link.

Fits many wire sizes.

Disadvantages:

Bad crimping makes weak links.

Not great in shaky spots without extra help.

Solder Connectors

Solder connectors make lasting links using solder to join wires tightly.

Types of Solder Connectors

Solder Sleeves: Mix solder with heat-shrink wrap for safe connections.

Solder Lugs: Attach wires to parts, strong for high-power needs.

Advantages and Disadvantages

Advantages:

Tough and long-lasting link.

Great for high-power uses.

Stands up to shakes and weather.

Disadvantages:

Takes more time and skill to set up.

Hard to undo once joined.

Push-On Connectors

Push-on connectors, or quick-disconnects, let you connect easily without tools.

Types of Push-On Connectors

Blade Connectors: Slide onto flat ends quickly and safely.

Bullet Connectors: Used in car radios, easy to plug in or out.

Advantages and Disadvantages

Advantages:

Fast connection or removal.

Good for places needing frequent access.

Comes in many sizes for different fits.

Disadvantages:

Can get loose if not secured well.

Not ideal in shaky areas without locks.

Knowing these automotive electrical connectors types helps choose the best one so car systems run smoothly and safely.

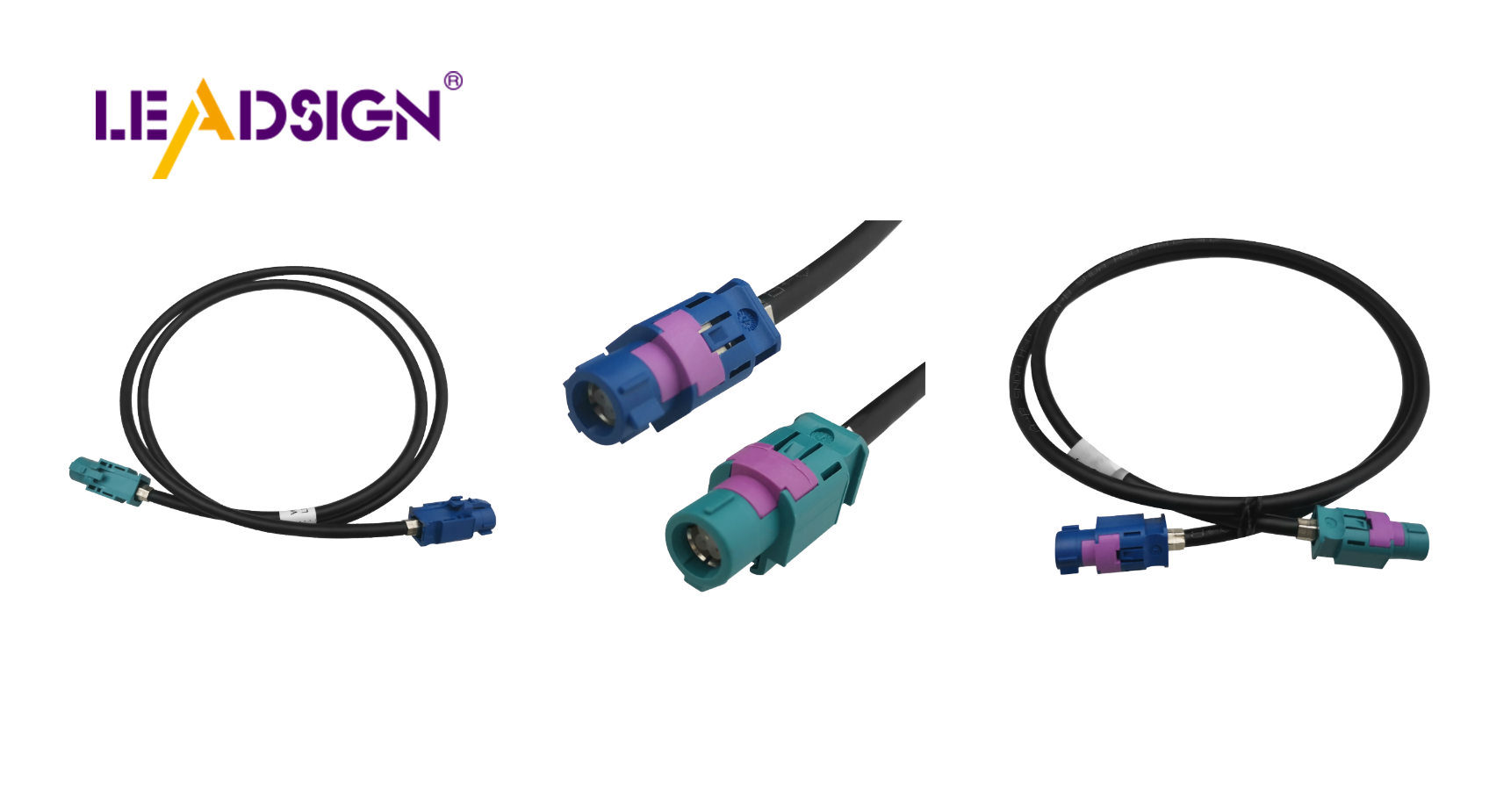

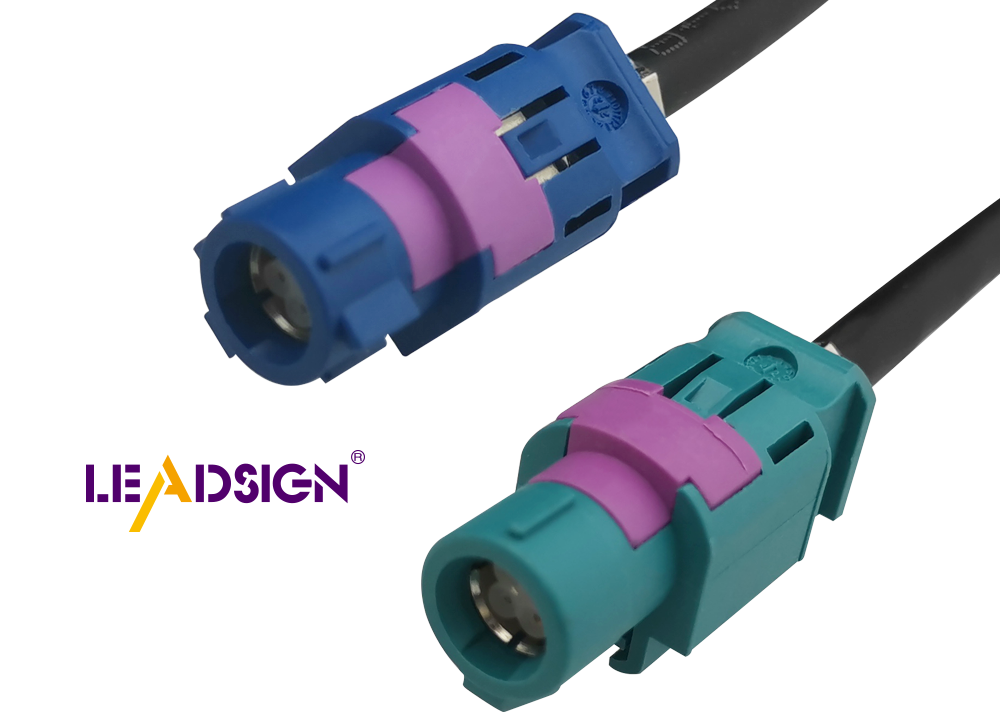

Specialty Connectors

Specialty connectors do special jobs in cars. They solve problems that regular connectors can't fix. These connectors are used in advanced car systems.

Examples of Specialty Connectors

Cable-to-Wire Connectors: These keep energy and information flowing well in cars. They help different car parts talk to each other.

Metal-to-Metal Connectors: Strong and tough, these work in hard places like engines. They last long and handle rough conditions.

Rectangular Connectors: Found in tricky systems like engine control, they connect many wires in a small space.

Bullet Connectors: Used for car radios, they make it easy to plug and unplug wires during fixes or upgrades.

Advantages and Disadvantages

Advantages:

Fit special needs in cars.

Make car systems work better and last longer.

Stand up well to bad weather and wear.

Disadvantages:

Need special tools or skills to put in.

Cost more than regular ones.

Not as easy to find as common types.

Knowing about specialty connectors helps pick the right one for each job. Choosing the right automotive electrical connectors types keeps cars safe and working well.

Choosing Wire Connectors

Picking the right automotive electrical connectors types is important. It helps car systems work well. You need to think about many things before choosing.

Environment Needs

Heat Resistance

Cars can get very hot or cold. Connectors must handle these temperatures. They should not stop working in heat or cold. For example, engine connectors need to resist engine heat. ITT Inc.'s Triton Series stays strong in tough places like electric cars.

Water Resistance

Water can harm connectors by causing rust and shorts. So, it's important to pick water-resistant ones. Sealed connectors, like those in Hirose Electric Co.'s HR41 Series, keep water out and work well in cars.

Electrical Needs

Current Capacity

Current capacity shows how much electricity a connector can carry safely. Picking the right one stops overheating problems. Powertrain systems need higher current ones for car power needs.

Voltage Capacity

Voltage capacity tells the highest voltage a connector can take. Right voltage stops electrical problems. In ADAS, connectors like HR41 Series must handle fast data and keep voltage safe.

Mechanical Needs

Strength

Strength matters when picking automotive electrical connectors types. They must survive shakes and hits in cars. Metal-to-Metal Connectors are strong and last long, great for engines.

Easy Setup

Easy setup saves time and cuts mistakes during building cars. Simple connectors like Push-On Connectors are best where you often fix or change parts.

By thinking about these points, you can choose the best automotive electrical connectors types for each job, keeping car systems safe and working well.

Choosing the right wire connectors is very important. They keep car systems safe and working well. Connectors help car parts talk to each other. They are key for safety tools like airbags and brakes. As technology gets better, connectors also improve. They become stronger and work better too. The market for car connectors will grow a lot, reaching USD 12.25 billion by 2032. This shows how important they are in today's cars. Knowing different types and uses helps keep cars safe and running smoothly.

See Also

Exploring the Fundamentals of HSD Connectors in Auto Sector

Benefits of HFM Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Implementations