Exploring Types of Wire Connectors in Automotive Applications

Automotive electrical connectors types are crucial components in vehicles. They play a vital role in ensuring effective electrical connections within the car. These connectors facilitate the transmission of signals between various devices and circuit boards. High-quality connectors are designed to meet stringent standards and withstand the challenging conditions present in modern vehicles. Automotive electrical connectors come in various types such as crimp, solder, and push-on connectors, each offering unique advantages. These connectors are essential for ensuring the safe and efficient operation of car systems.

Types of Wire Connectors

Crimp Connectors

Crimp connectors are a common choice in cars. They work by squeezing the connector around the wire tightly. This makes a strong connection if done right. Crimp connectors save time when putting cables together.

Advantages of crimp connectors:

Fast to install

Strong connections with the right tools

Seals keep out moisture

But there are disadvantages:

Bad results if not crimped properly

Can fail with solid wires if done wrong

Stranded wires might loosen if bent often

Solder Connectors

Solder connectors use melted solder to join wires and connectors. This makes a strong, lasting connection, good for important uses.

Advantages of solder connectors:

Very strong and lasting connections

Works well for reducing signal problems

Good for high-frequency uses

But solder connectors have disadvantages:

Takes longer to install

Needs skilled people to do it right

Heat can harm delicate parts

Push-On Connectors

Push-on connectors, or quick-connects, are easy to use in cars. You can attach and remove them without tools, great for things you unplug often.

Advantages of push-on connectors:

Easy and fast to use

No special tools needed

Good for low-power uses

But they have disadvantages:

Not as secure as other types

Only fit certain uses due to low power limits

Might disconnect by accident in shaky places

Specialty Connectors

Specialty connectors have special jobs in cars. They do things that regular connectors can't. Two important types are High-Speed Data (HSD) Connectors and Waterproof Connectors.

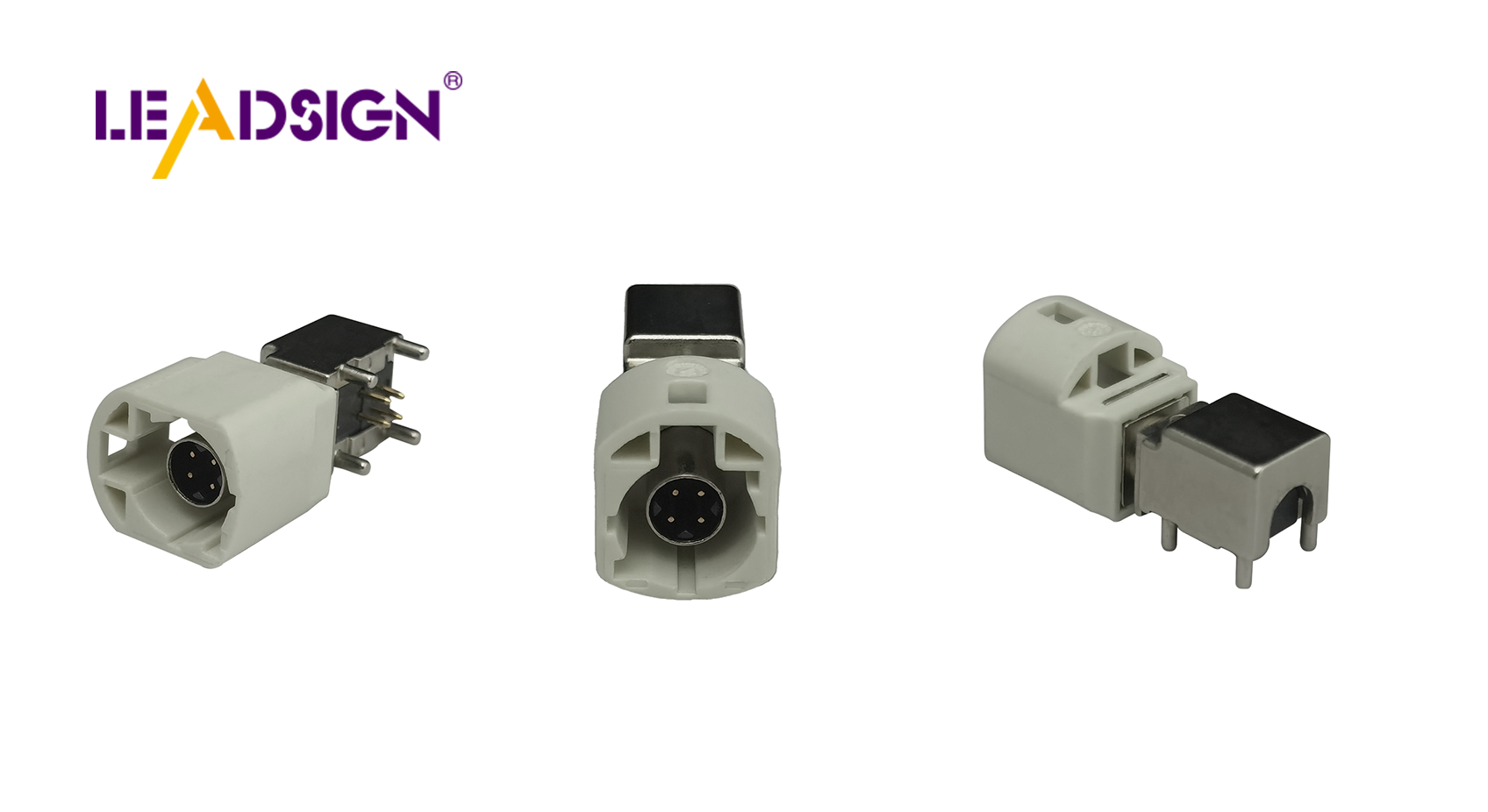

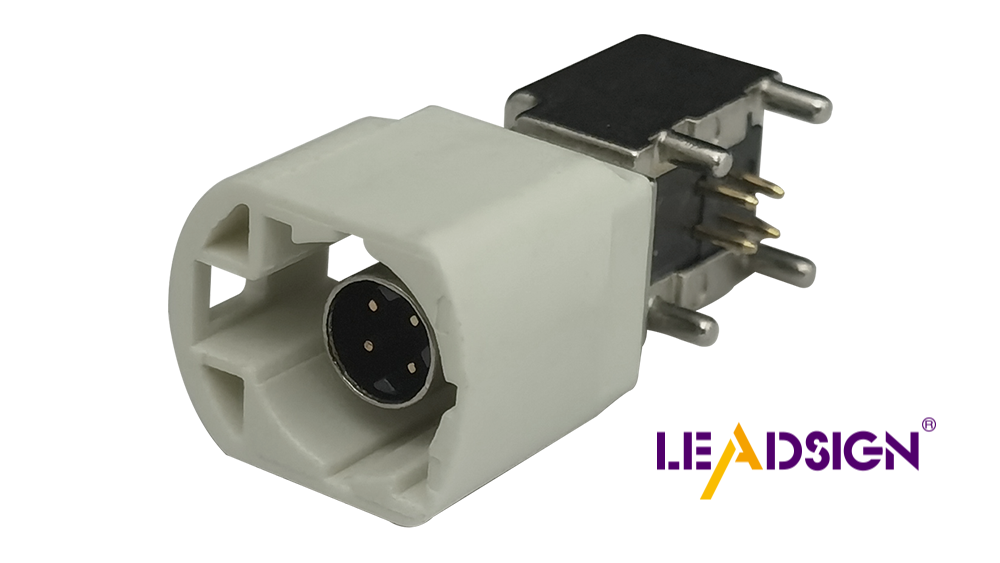

High-Speed Data (HSD) Connectors

HSD connectors are very important in new cars. They help send data really fast. This is great for car electronics like cameras and USBs. These connectors make sure systems talk to each other well.

Key Features of HSD Connectors:

Primary and Secondary Lock: Keeps connections tight.

Crimp Connection: Makes a strong link.

High Cable Retention Force: Stops cables from coming loose.

High Coding Efficiency: Prevents wrong connections.

HSD connectors work in cars and telecom places too, like radio stations. They fit many standards, such as USB and Ethernet, so they work with lots of devices.

Waterproof Connectors

Waterproof connectors are also crucial in cars. They can handle tough conditions like rain, dust, and heat. They keep electrical parts safe where it's wet or dirty.

Advantages of Waterproof Connectors:

Sealed Design: Stops water from getting inside.

Durability: Handles temperature changes well.

Versatility: Works in many car parts, like engines and lights.

Waterproof connectors work well even when it's hard outside. They help keep car systems safe and working right. Their strong build makes them needed where water might be a problem.

Standards and Testing

Industry Standards

Car wire connectors must follow strict rules. This keeps them safe and reliable. USCAR-2 and ISO 20076:2019 are important rules. They help design and test these connectors. USCAR-2 is made by the Society of Automotive Engineers (SAE). It tells how strong car wires should be. It wants them to last long through tough tests. ISO 20076:2019 checks voltage class B connectors. It makes sure they work well.

"Using low PIM parts can stop this issue. The connector and cable need to show low PIM." - RF Industries

Following these rules is very important. It makes sure car wire connectors can handle tough car conditions. Makers must meet these rules for good quality and work well. This not only makes things safer but also makes people trust the product more.

Testing Procedures

Testing car wire connectors involves hard checks to ensure they work well. Common tests include shaking and heat changes. These tests copy the hard times connectors face in cars. Shaking tests check if the connector stays tight when moving a lot. Heat changes see if it works in hot or cold places.

Checking for problems with hard tests is key. Makers do these checks to find weak spots in connectors early on. They fix issues before selling them, stopping problems later on, making them last longer, and ensuring they work great in real life.

Performance and Reliability

Factors Affecting Performance

Automotive electrical connectors face many challenges. These can change how they work. Things like heat and wetness are big factors. Hot weather makes parts expand, causing loose links. Wetness can rust them, hurting their ability to carry electricity. So, picking connectors that handle these well is key.

The quality of materials also matters a lot for performance. Good materials mean strong and reliable connectors. For example, using metals that resist rust works better in tough places. The material choice affects how long the connector lasts and stays strong under pressure.

Enhancing Reliability

To make automotive electrical connectors more reliable, good installation is important. Doing it right stops problems and keeps them working well for a long time. Installers should use the right tools to avoid breaking them. Like using a proper crimp tool makes a tight link, lowering failure chances.

Regular check-ups help connectors last longer too. Looking for wear or damage stops surprise failures. Cleaning them often removes dirt or rust that could hurt their function. Following these care tips keeps automotive electrical connectors working well over time.

"Special solder connectors are best for low PIM needs, while crimp ones usually have bad PIM." - Passive Intermodulation (PIM) and Cable Assemblies

This shows why choosing the right connector is important for each job. Solder ones with low PIM are great for high-signal jobs. Knowing what each type does best helps make smart choices in car uses.

Picking the right wire connectors is very important. It keeps car systems safe and working well. Good connectors, like those that meet industry rules, are strong and last long. When choosing connectors, people should think about industry rules and how they work. This makes sure they can handle bumps and heat changes without breaking.

"Car safety features need electronic parts linked by these connectors."

For more help, people should look up more info or ask experts to choose wisely.

See Also

Exploring the Advantages of HSD Connectors in Automotive Applications

Uncovering the Advantages of Fakra Connectors in Auto Industry

Significance of FAKRA Connectors in Automotive Sector