What Are the Types of Automotive Electrical Connectors?

Automotive electrical connectors are crucial in modern vehicles, ensuring the efficient operation of the car's systems by securely connecting wires. The significance of these connectors is reflected in their market value, which stands at USD 7.86 billion in 2023 and is projected to reach USD 11.76 billion by 2031. This anticipated growth highlights the variety of automotive electrical connectors types, each designed for specific applications and requirements. Understanding these connectors is essential for anyone interested in automotive technology.

Overview of Automotive Electrical Connectors

Definition and Function

Basic definition of electrical connectors

Electrical connectors are key parts in cars. They help connect electrical circuits. These connectors let power and signals move between car parts. They make sure the car's systems work well.

Importance in automotive systems

Connectors are very important in car systems. They give strong connections needed for electronic parts to work. As cars get more high-tech, we need better connectors. Automotive Electrical Connectors help electric cars by sending power and improving how they run.

General Characteristics

Material composition

The materials used in these connectors affect how they work. Makers use strong stuff like nylon and polypropylene. These materials help them handle tough conditions like heat and shaking. The Triton Series Automotive Connector is good at sealing and handling vibrations, so it works well in hard places.

Design considerations

Design is crucial for good automotive connectors. Designers aim to make them fit modern car needs, including electric ones. The Connector Experts Automotive Connectors show top designs for different car uses. Some old-style connectors are still used today because they are reliable.

Types of Automotive Electrical Connectors

Car connectors are important for a car's electrical system. They come in different types, each made for special jobs in cars.

Wire-to-Wire Connectors

What they do and where used

Wire-to-wire connectors join two wires together. They help send power and data between car parts. These connectors are needed in airbags, brakes, and car locks. As cars get smarter, we need stronger wire-to-wire connectors for systems like driver aids and music players.

Examples you might know

Some wire-to-wire connectors are crimp, bullet, and spade terminals. Crimp ones hold tight by squeezing onto the wire. Bullet ones are easy to use and quick to connect or disconnect. Spade terminals look like forks and give strong connections in cars.

Wire-to-Board Connectors

What they do and where used

Wire-to-board connectors link wires to circuit boards inside a car. They connect sensors and control units to the main system. This helps share energy and info between electronic parts, supporting new tech like electric engines and self-driving features.

Examples you might know

Wire-to-board examples include pin headers, socket connectors, and terminal blocks. Pin headers make it easy to attach wires to a board. Socket connectors securely join electronic parts together. Terminal blocks let you easily connect or disconnect wires in control panels.

Board-to-Board Connectors

What they do and where used

Board-to-board connectors join two circuit boards inside a car. They help move power and messages between different modules in modern cars with complex systems.

Examples you might know

Examples include mezzanine, card edge, and backplane connectors. Mezzanine ones save space by stacking boards together. Card edge ones fit well with boards that have edge contacts. Backplane ones work fast for sharing data between many boards.

Car connector types keep cars working safely today. As tech grows, we will need even better connectors showing how key they are in the car world.

Factors Affecting Connector Choice

Environmental Factors

Heat and Wetness Resistance

Automotive electrical connectors need to handle different weather. Heat and wetness can change how they work. Makers build them to resist hot and cold. The Triton Series Automotive Connector seals well, good for electric cars. This stops water from getting in, avoiding rust and breaks.

Shake and Bump Resistance

Cars move a lot, causing shakes and bumps. Connectors must stay strong to keep working right. The Triton Series handles shakes well, lasting in tough spots. This is key for keeping systems safe, especially in bumpy or fast cars.

Power Needs

Electricity Strength

Connectors have to fit power needs for safety. They have limits on electricity they can take. High-power ones by Continental AG are better at moving electricity and staying cool. These make sure connectors handle power safely in new cars.

Signal Quality

Keeping signals clear is important for car parts to work right. Connectors send signals without losing them. Better designs help with signal quality, like in high-power types. This makes sure data moves smoothly for smart tech like self-driving.

To sum up, picking the right connector means thinking about weather and power needs. Makers keep improving so connectors stay strong and work well everywhere.

Picking the right car connector is very important. It keeps cars safe and working well. Good connectors make sure electric parts connect right. This helps important car parts work properly. As tech gets better, we need new connector designs. These new designs must still work well and meet needs. Knowing about connectors helps us choose better ones. This makes car systems more reliable and efficient.

See Also

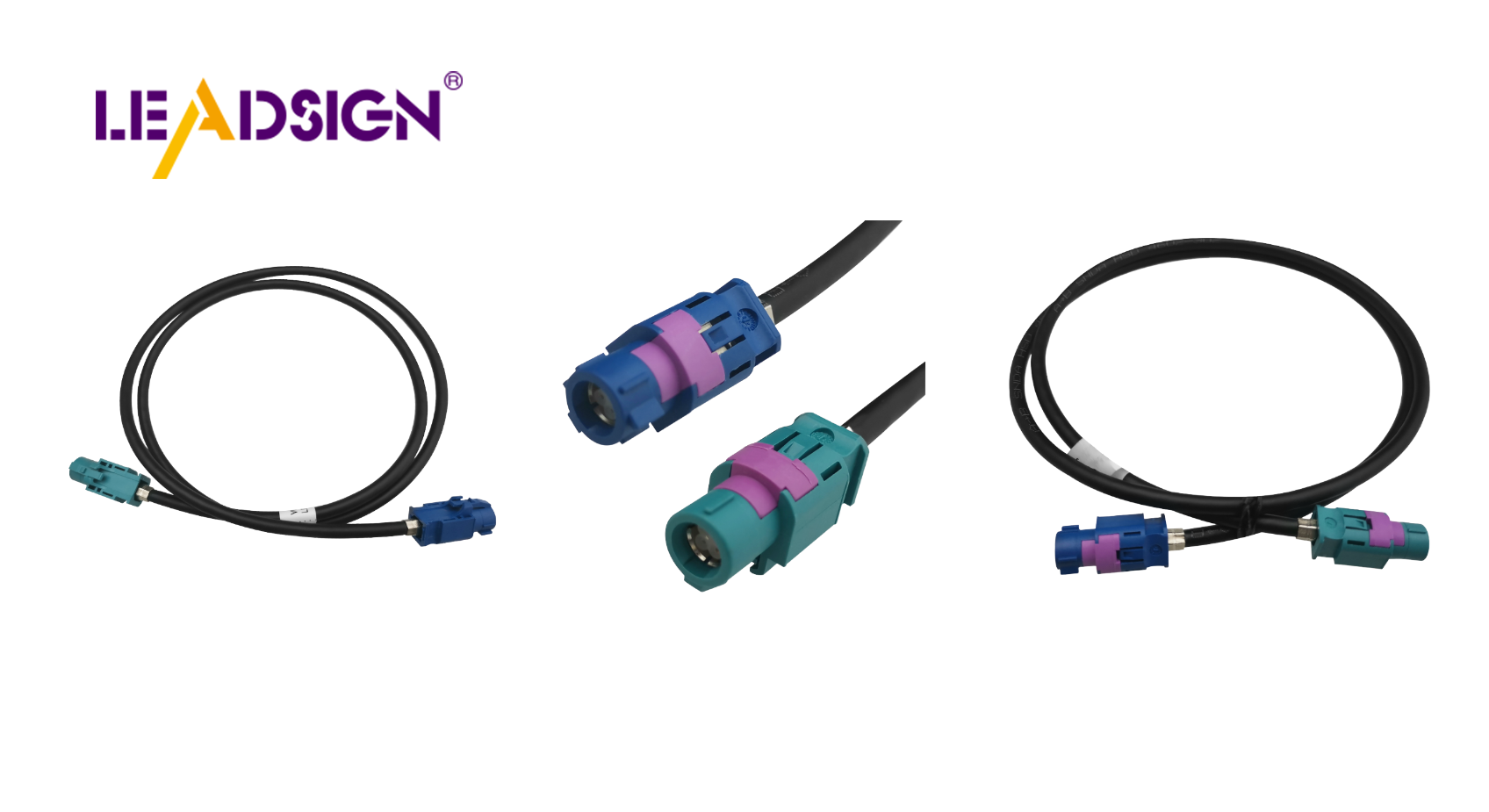

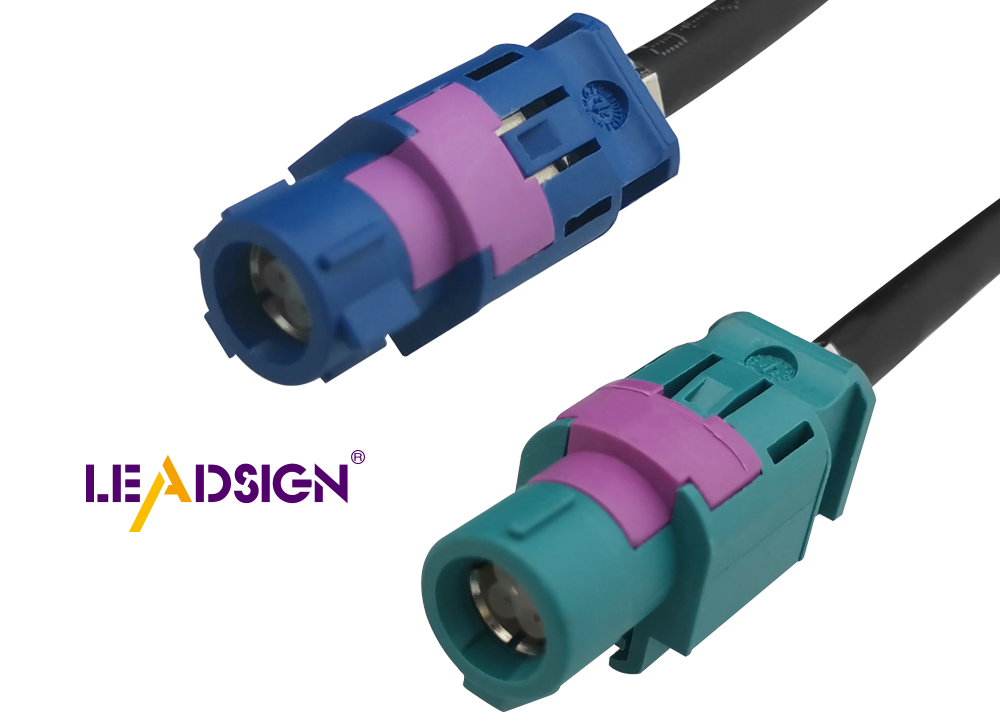

Exploring HSD Connectors in the Automotive Sector

Significance of FAKRA Connectors in Contemporary Cars

Essential Role of FAKRA Connectors in Auto Uses

Benefits of HFM Connectors in Automotive Sector

Enhancing Auto Data Transfer: Advanced Connectors and Cables