Troubleshooting Common Issues in Vehicle Connectors

Vehicle connectors are important for keeping your car working well. These small parts help power and signals move between electrical systems. Without them, things like lights, GPS, and communication might stop working. Over time, rust, loose parts, or damage can cause problems. These issues make your car less efficient and may cost a lot to fix. Checking and fixing them regularly can prevent these problems. This keeps your car safe and dependable while driving.

Key Takeaways

Regularly check vehicle connectors for rust, dirt, and damage to prevent electrical issues and ensure reliable performance.

Use dielectric grease on connectors to protect against moisture and corrosion, extending their lifespan and maintaining electrical flow.

Clean connectors with a safe cleaner to remove dirt and rust, ensuring they function properly and avoid overheating.

Test connections with a multimeter to quickly identify issues; a good connection will show low resistance.

Replace damaged connectors with high-quality OEM parts to ensure compatibility and reliability in your vehicle's electrical systems.

Avoid overloading connectors by adhering to manufacturer specifications for power limits, preventing overheating and potential failures.

Make a habit of labeling connectors during maintenance to simplify reassembly and avoid mistakes.

Understanding Vehicle Connectors

Vehicle connectors are key to your car's electrical systems. They let power and data move between parts easily. Without them, things like lights, GPS, and safety features wouldn't work. Knowing their purpose helps keep your car reliable.

The Role of Vehicle Connectors

Vehicle connectors are like your car's electrical backbone. They send signals and power to the right places. For instance, pigtail connectors join wires to sensors and switches. This helps systems talk to each other properly. These connectors handle tough conditions like heat and rust. Taking care of them stops problems and keeps your car running well.

Types of Automotive Electrical Connectors

There are different kinds of automotive connectors, each with a job. Knowing them helps you fix issues faster.

Pin Connectors

Pin connectors are common in cars. They use metal pins to connect wires securely. These are great for sending signals, like in engine controls or screens. Their small size fits tight spaces in vehicles.

Blade Connectors

Blade connectors are flat metal pieces that slide into slots. They're used in fuse boxes and other quick-connect areas. Their simple design makes them easy to use and remove.

Weatherproof Connectors

Weatherproof connectors block water, dirt, and more. They're used for headlights, taillights, and outdoor sensors. Their sealed design keeps them working in bad conditions. They stop water or dirt from causing problems.

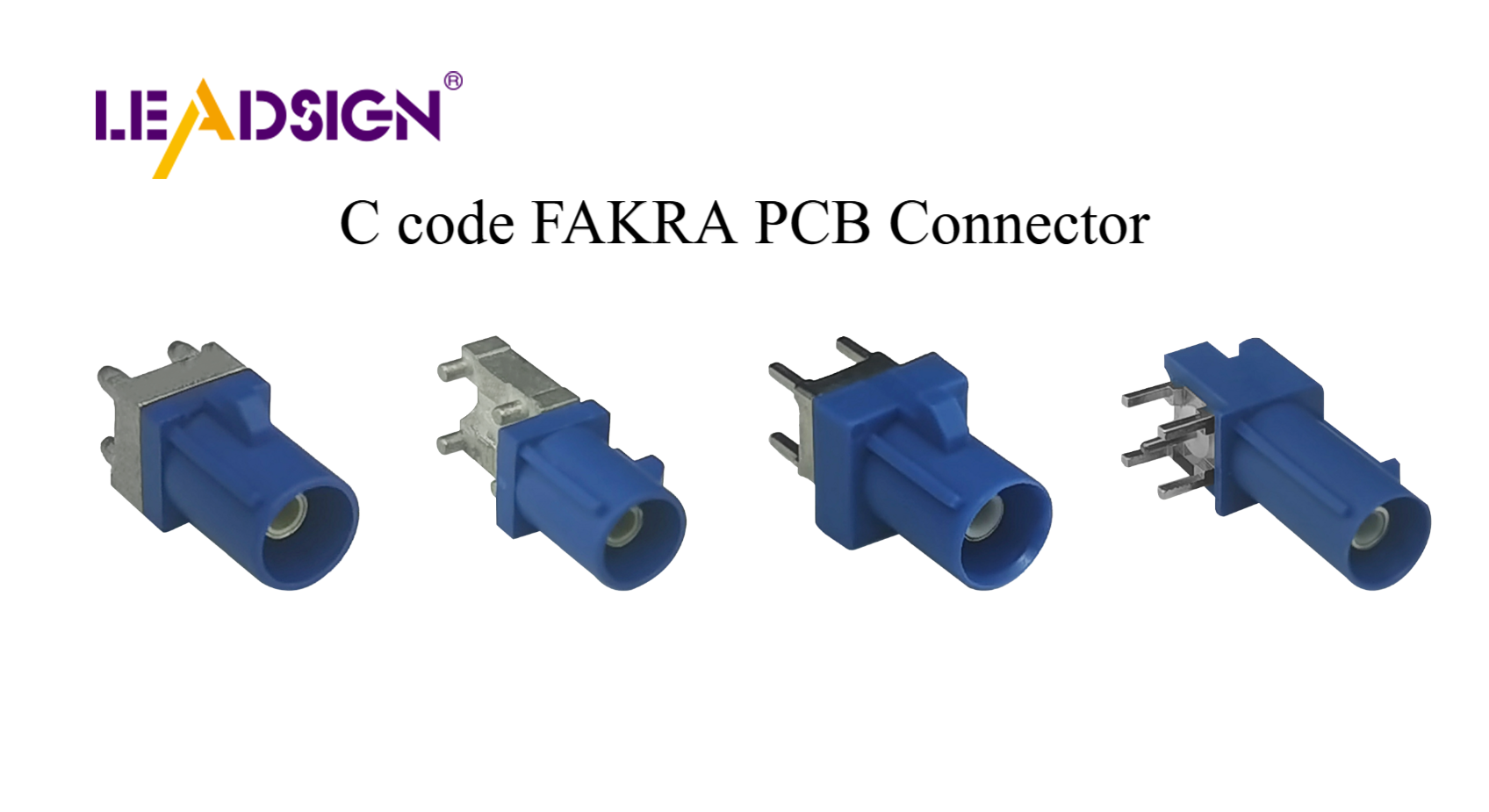

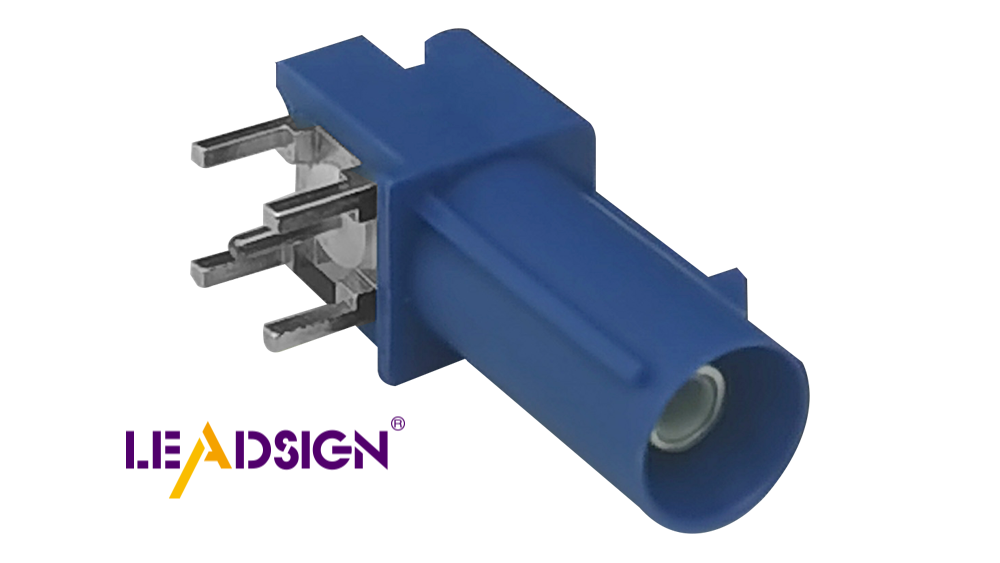

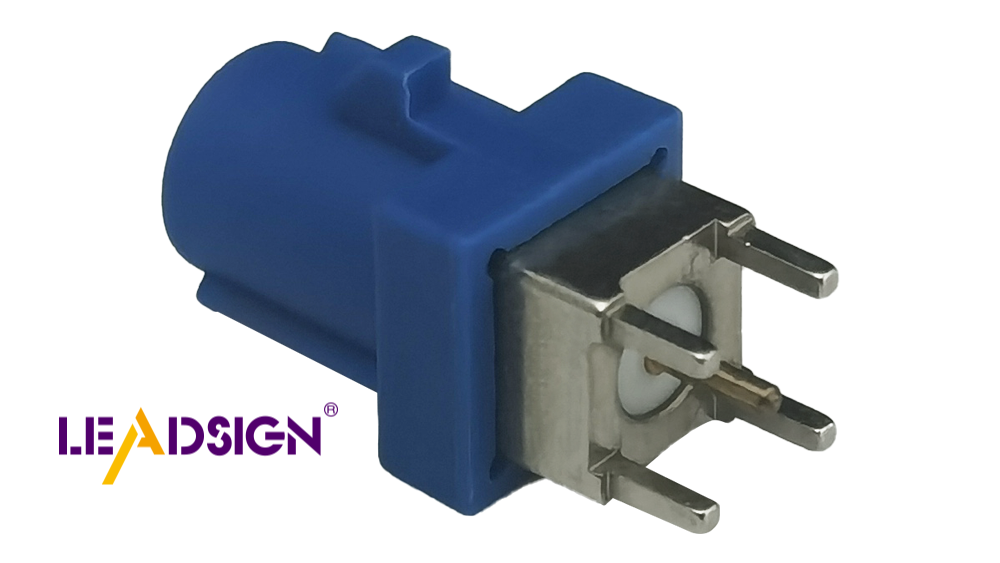

FAKRA Connectors and Their Applications

FAKRA connectors are special for high-frequency car systems. They're in GPS, radios, and Bluetooth setups. They have many advantages:

Durability: Built to handle tough car demands.

Secure Coding System: Stops wrong connections.

Space-Saving Design: Fits in small spaces.

High Performance: Works with fast data and signals.

FAKRA connectors are vital for modern cars with advanced systems. They ensure smooth communication and reliable performance.

Common Problems in Vehicle Connectors

Vehicle connectors can have problems that affect your car's performance. Knowing these issues helps you fix them and avoid bigger troubles.

Rust and Its Causes

Rust is a frequent problem in vehicle connectors. Water, road salt, and moisture make metal parts rust. Rust blocks electricity, causing poor performance or system failures. For example, rusty connectors might confuse sensors, leading to false errors. Checking and cleaning connectors often can stop this. Using original car connectors lowers rust risks since they handle tough conditions well.

"Rust can weaken electricity flow, making sensors give wrong signals."

— Charlie Groeller, Retired Electrical Engineer

Loose Connections from Wear or Shaking

Driving vibrations and wear can loosen connections over time. Loose connectors stop electricity, causing flickering lights or broken systems. Weak grounding also hurts electrical performance. You can avoid this by checking connectors and tightening them. Reliable pigtail connectors help keep strong connections and prevent common problems.

Damage from Heat and Dirt

Heat, dirt, and debris can harm vehicle connectors. Broken pins, melted parts, or cracks can stop electricity and reduce safety. Look for damage often to catch problems early. Replacing bad parts with strong original connectors keeps your car reliable. These connectors also protect warranties, making them a smart long-term choice.

Dirt and Debris Causing Electrical Problems

Dirt and debris can block power in car connectors. When dirt builds up, it stops metal parts from touching properly. This weakens the connection and causes problems like dim lights or broken sensors.

To fix this, check your connectors for dirt often. Clean them with a safe contact cleaner to keep them working. Always turn off the power before cleaning to stay safe. Clean connectors work better and stop overheating damage.

Using good-quality connectors, like OEM ones, helps avoid these issues. OEM connectors are strong and resist dirt, keeping your car's warranty safe. They are a smart choice for long-term use.

Adding dielectric grease to connectors also helps. It blocks dirt and water, keeping the connection strong. Clean and protected connectors make your car more reliable and save you money on repairs.

Step-by-Step Troubleshooting Guide

Checking Vehicle Connectors

First, look closely at the vehicle connectors. Check for rust, dirt, or damage. Rust may look like green or white powder. Dirt can block electricity, and cracks show heat damage. Loose connections happen from shaking or wear over time.

Label all connectors before unplugging them. This helps you reconnect them correctly later. Look at the wiring for cuts or damage that stop electricity. Careful checking finds problems early and avoids bigger issues.

"Rust and wear often cause connector problems, hurting performance."

— TruckingInfo Journal

Cleaning Car Electrical Connectors

Cleaning connectors helps them work properly again. Turn off the power first to stay safe. Use a cleaner made for plastic to remove dirt and rust. Spray it on the connectors and wait a few seconds. Then, gently scrub with a soft brush or cloth.

For tough rust, mix baking soda with water. Use a toothbrush to apply it, then rinse well. Dry the connectors fully before putting them back. Add a little dielectric grease to block water and stop future rust.

Regular cleaning keeps connectors working well and reliable.

Testing Connections with a Multimeter

A multimeter checks if connectors work right. Set it to continuity mode. Put one probe on the connector pin and the other on the wire. A beep or low number means the connection is good. No sound or high numbers mean it’s broken.

Test all pins and wires in the connector. This finds where the problem is. Replace bad connectors with strong ones to keep your car's system working well.

"Good connectors last longer and prevent failures."

— Eigen Engineering Journal

Fixing or Changing Broken Connectors

When a vehicle connector breaks, fixing or replacing it is important. Broken connectors stop electricity, causing systems to fail or not work right. Fixing these problems quickly keeps your car safe and dependable.

How to Fix Broken Connectors

Fixing a connector needs careful steps. Follow these simple instructions:

Check the Connector

Look for damage like bent pins, melted parts, or rust. Use a magnifying glass to see small cracks or worn spots.Clean the Connector

Get rid of dirt, rust, or grime with a safe cleaner. For tough rust, use a mix of baking soda and water with a toothbrush. Rinse and dry it completely before moving on.Fix Bent Pins or Wires

Straighten bent pins gently with pliers. If wires are broken, cut the bad part and reconnect it using a crimping tool or solder. Make sure the connection is tight to avoid future problems.Test the Connection

Use a multimeter to check if the fixed connector works. A good fix will show low resistance, meaning electricity flows well.

"Fixed connectors can make your car's systems last longer."

— Mesquite Local News

When to Change Broken Connectors

Sometimes, fixing a connector isn’t enough. Big damage, like melted parts or missing pieces, means you need a new one. Follow these tips to replace it:

Pick the Right Connector

Always choose a strong connector that matches the original one. OEM connectors are best for lasting quality. Cheap parts can cause more problems later.Unplug the Wiring Harness

Carefully remove the wiring harness from the broken connector. Label each wire to avoid mistakes when reconnecting.Attach the New Connector

Connect the new part to the wiring harness. Use crimping tools or solder, depending on the type. Check that all wires are tight and in the right place.Test the System

Plug the harness back in and test the system. Make sure everything works without any electrical issues.

"Good connectors lower failure risks and last a long time."

— Eigen Engineering

Why Experts Can Help

If fixing or replacing connectors feels hard, ask an expert. Professionals have the right tools and skills for tricky electrical work. This avoids more damage and keeps your car running well.

Fixing broken connectors quickly stops bigger problems. Regular checks and repairs keep your car working smoothly and save money on repairs.

Tips to Keep Vehicle Connectors Working Well

Taking care of connectors keeps your car's electrical parts reliable. Simple steps can stop expensive repairs and keep your car running.

Check Connectors Often

Look at connectors regularly to avoid sudden problems. Check for rust, dirt, or damage. Loose connections can happen from shaking or wear. Pigtail connectors are important because they link key parts. Regular checks catch small problems early.

Make a habit of checking connectors. Label wires so you don’t mix them up later. Use a magnifying glass to find cracks or bent pins. If damaged, replace with strong connectors like OEM ones. These last longer and fit better.

"Checking connectors often stops surprise breakdowns."

— Car Experts

Use Dielectric Grease for Protection

Dielectric grease protects connectors from water, dirt, and rust. It stops corrosion that can break electrical flow. Adding grease during maintenance keeps connectors working in tough conditions.

First, clean the connectors well. Use a safe cleaner to remove dirt and rust. Let them dry, then add a little grease to the metal parts. This blocks dirt and makes connectors last longer. Using grease regularly keeps your car dependable.

Don’t Overload Connectors

Too much power can overheat and break connectors. Each connector can only handle a certain amount of electricity. Going over this limit damages them and connected systems. Follow the maker’s rules for power limits.

When adding new gadgets, check if connectors can handle it. Use strong connectors made for high power, like those for electric cars. These are built for tough jobs and share power safely. Avoiding overloads keeps your car’s systems safe.

"Right connectors give safe and steady power."

— Car Experts

Taking care of connectors with checks, grease, and no overloads keeps your car running well.

Keeping Connectors Clean and Free of Dirt

Clean connectors help your car work well and avoid repairs. Dirt and grime can block electricity, causing dim lights or broken sensors. Cleaning them often keeps your car running smoothly.

First, check your connectors for dirt or buildup. Use a cleaner safe for plastic to remove dirt. Spray the cleaner on the connector and wait a few seconds. Then, gently scrub with a soft brush or cloth. Always turn off the power before cleaning to stay safe.

Connectors in tough spots, like weatherproof ones, need extra care. These face water, mud, and salt, which cause rust. After cleaning, add a thin layer of grease to the metal parts. This grease blocks water and dirt, keeping connectors safe.

Storing connectors properly also helps keep them clean. Pick a safe spot to store them to avoid losing them. Use sealed bags or containers to block dust and moisture. This keeps connectors in good shape for future use.

Cleaning and storing connectors well makes them last longer. It also keeps your car’s electrical systems working better. These steps prevent breakdowns and keep your car reliable.

Knowing and taking care of vehicle connectors keeps your car working well. Check them often, clean them, and fix any problems quickly. Simple steps like looking for rust or using a multimeter can stop big issues. Keep connectors in a clean and safe place to make them last longer. These easy habits save money and help your car stay reliable for a long time.

FAQ

What are the signs of a bad vehicle connector?

You may see flickering lights or sensors not working. Sometimes, electrical problems happen on and off. These issues can mean loose parts, rust, or dirt in connectors. Checking them often helps you find problems early and avoid surprises.

How often should I check my vehicle connectors?

Check your connectors every three to six months. This helps you find rust, dirt, or damage before big problems start. Regular checks keep your car safe and working well.

Can I clean vehicle connectors myself?

Yes, you can clean them with the right tools. Use a cleaner safe for plastic to remove dirt and rust. Always turn off the power first to stay safe. For tough rust, use a mix of baking soda and water with a toothbrush. Dry them completely before putting them back.

How can I stop connectors from rusting?

Use dielectric grease on the metal parts of connectors. This grease keeps water and dirt away, stopping rust. Adding it during regular care keeps connectors in good shape.

How do I check if a connector works?

Use a multimeter set to continuity mode. Put one probe on the pin and the other on the wire. A beep or low number means it works. No sound or high numbers mean it might need fixing or replacing.

When should I replace a connector instead of fixing it?

Replace a connector if it’s badly damaged. This includes melted parts, missing pieces, or heavy rust. Fixing these might not work well. Always pick strong replacements for better performance.

How can I keep dirt from messing up my connectors?

Check and clean your connectors often. Use a safe cleaner to remove dirt. Store unused connectors in sealed bags or containers. This stops dust and moisture from building up.

Are OEM connectors better than other ones?

OEM connectors are made to fit your car perfectly. They last longer and work better than many other options. Using OEM connectors also protects your car’s warranty.

Can too much power break a connector?

Yes, too much power can overheat and ruin connectors. Each connector has a limit for how much power it can handle. Follow the maker’s rules to avoid damage.

Why is it important to care for pigtail connectors?

Pigtail connectors connect important parts in your car. Taking care of them stops electrical problems and keeps things working well. Clean and check them often to avoid sudden failures.

See Also

Why Fakra Connectors Matter for Honda Cars

Enhancing Vehicle Data Flow with Advanced Connectors

Fakra Connectors: Essential for Today's Automotive Technology

Understanding HSD Connectors in Modern Automotive Applications

Boosting Data Transfer with High-Speed Automotive Connectors