Understanding Trends in Automotive Electrical Connectors Types

Automotive electrical connectors are crucial in today's vehicles, facilitating seamless power and data transfer between components. As vehicles become more technologically advanced, the demand for superior connectors increases. The market for these connectors is projected to reach $15.2 billion by 2030, growing at an annual rate of 5.4%. This underscores the significance of connectors like the HSD PCB Connector, which enable high-speed data transmission. Emerging automotive electrical connectors types are transforming the functionality of future vehicles.

Overview of Car Electrical Connectors

What They Are and How They Work

Car electrical connectors are important parts. They help electricity and data move inside a car. These connectors make sure the engine and music system talk to each other well.

Main Parts

Car electrical connectors have three main parts: terminals, housings, and seals. Terminals carry electricity. Housings hold everything together safely. Seals keep water and dirt out, making them last longer. Each part is key to keeping connections strong.

Importance in Cars

Connectors help link many electric parts in cars. They join sensors, control boxes, and gadgets so the car works right. The HSD PCB Connector helps send fast data for things like car radios and self-driving tech.

History of Development

The growth of car connectors shows how cars got better over time. Long ago, they were simple plugs but now they're fancy wireless systems.

Changes Over Time

At first, cars used basic wire plugs. As more electric parts were added, better connectors were needed. Fiber optic plugs came next for faster data sharing. Now we see wireless ones in fancy cars.

Big Improvements

New ideas in car connectors include ones that send more data faster. This helps with clear signals and quick data sharing for car radios and self-driving features, showing how these connectors keep getting better.

Current Trends in Automotive Electrical Connectors

Miniaturization

Making connectors smaller changes car design. Tiny connectors save space and cut weight, which is important for new cars.

Benefits and Challenges

Miniaturization has good points:

Space Efficiency: Small connectors leave room for other parts.

Weight Reduction: Light connectors help the car work better.

But there are problems:

Complex Manufacturing: Making tiny parts needs care.

Heat Management: Small size can cause heat issues.

Impact on Vehicle Design

Smaller connectors let cars be compact and efficient. Designers add features without making cars bigger. This helps electric and hybrid cars where space matters.

Increased Durability and Reliability

Connectors must last long and work well. Makers use better materials to improve them.

Material Advancements

New studies show materials that handle high heat, rust, and wear. These keep connectors strong in tough places.

High-Temperature Resistance: New stuff handles hot temps.

Corrosion Resistance: Better materials stop rust.

Testing and Standards

Makers follow strict tests to ensure quality. These include:

Environmental Testing: Mimicking real conditions.

Safety Standards: Meeting rules for safety.

Integration with Advanced Technologies

Car connectors now link with smart tech, boosting connectivity for cool things like self-driving cars.

Connectivity and IoT

Connectors are key in car IoT. They help devices talk easily, making things better for users.

Data Transmission: Connectors like HSD PCB move data fast.

Smart Features: Link with smart systems smoothly.

Autonomous Vehicles

In self-driving cars, connectors support tricky systems needing steady data flow. They make sure sensors talk right, crucial for safety.

"Future connectors will have safety features and resist harsh environments." — Connector Experts

These trends show how automotive electrical connector types focus on new ideas and tech changes.

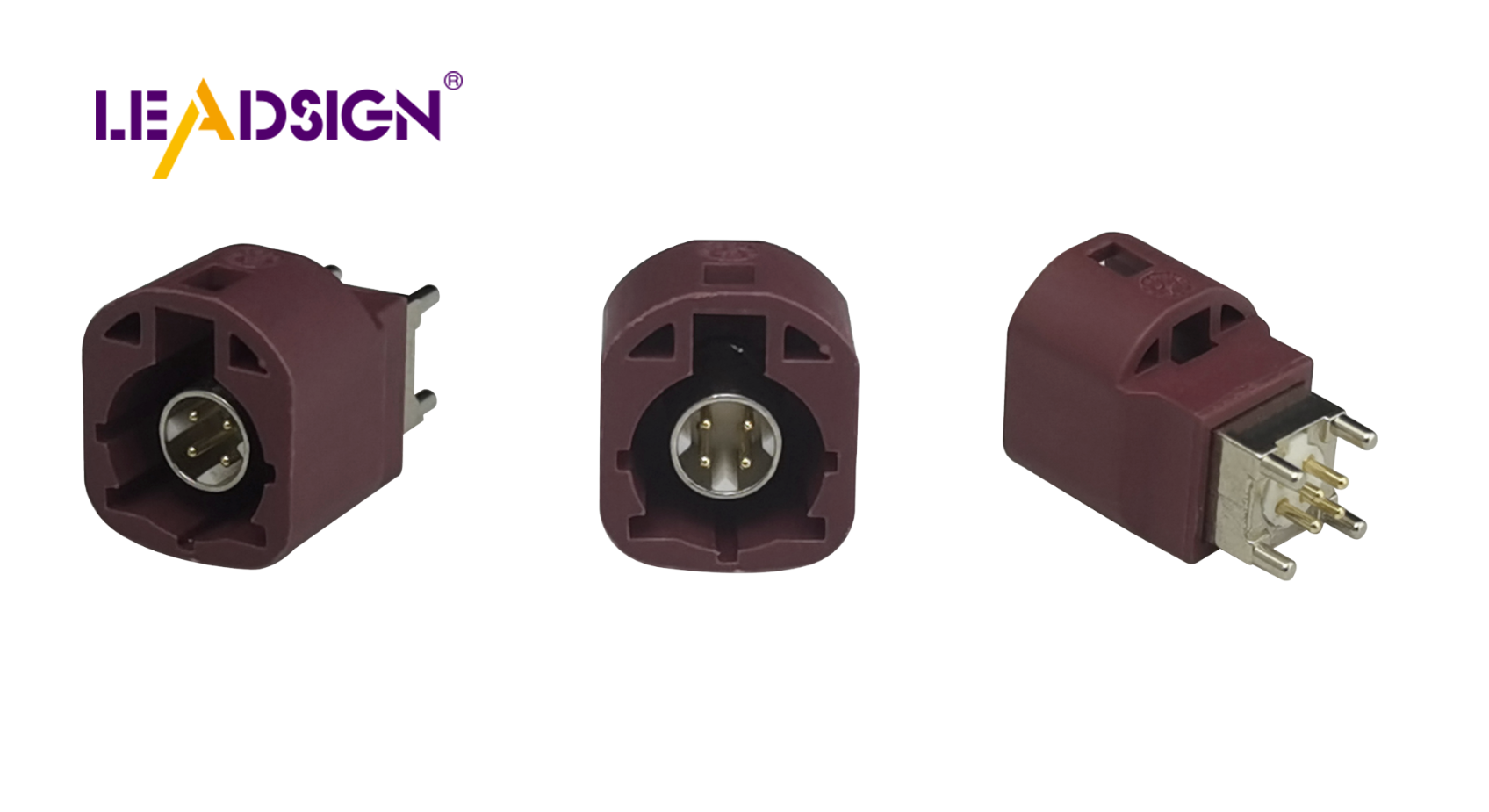

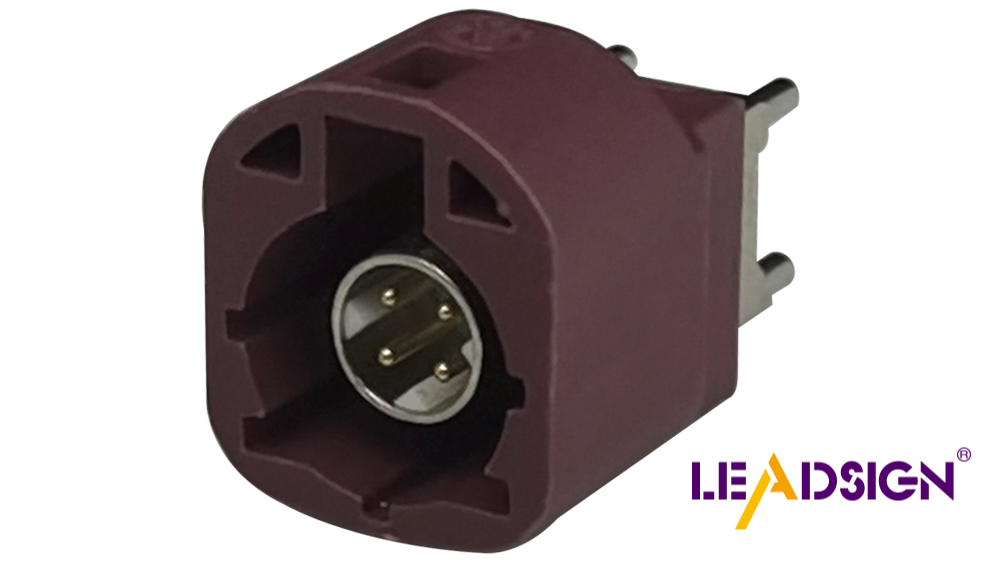

HSD PCB Connector and Its Role

Understanding HSD PCB Connector

The HSD PCB Connector is important in new cars. It helps send fast data, needed for smart car systems.

Features and Benefits

The HSD PCB Connector has many good features:

Primary and Secondary Lock: Keeps connections safe.

Crimp Connection: Makes sure electricity flows well.

High Cable Retention Force: Stops cables from coming loose.

High Coding Efficiency: Avoids wrong connections with different codes.

These features make the connector strong and useful in cars.

Applications in Automotive Systems

The HSD PCB Connector is used in many car systems:

Digital Infotainment: Helps send fast data for music and videos.

Autonomous Vehicles: Lets sensors talk to control parts.

Telecom Industries: Used in radio stations for strong data links.

These uses show how flexible and important the connector is today.

Impact on Automotive Electrical Connectors Types

The HSD PCB Connector changes car connectors by boosting data speed and helping new tech.

Enhancing Data Transmission

Cars need fast data flow more than ever. The HSD-compatible MX65 connector series meets this need by moving data quickly. This is key for cameras and USB ports, making sure everything talks smoothly inside the car.

Supporting Advanced Vehicle Technologies

New car tech needs strong connectors. The HSD PCB Connector helps these techs by:

Facilitating IoT Integration: Links smart gadgets inside the car.

Enabling Autonomous Features: Ensures steady data swap for self-driving tasks.

These help make the HSD PCB Connector a big part of new car connectors.

Factors Driving Trends

Consumer Demand

Preferences for Advanced Features

People want cars with cool features. They like easy connections, better music systems, and self-driving abilities. This makes car makers create smart connectors. Fast data and strong links are needed as people expect more from cars.

Environmental Concerns

People care about the earth. They choose green cars to cut pollution. This change makes car companies use light materials and smart designs. Connectors help by being light and saving energy. So, makers focus on eco-friendly connectors.

Regulatory Requirements

Safety Standards

Rules make sure car connectors are safe. These rules keep connectors working well in a car's life. The USCAR-20 Standard shows how important good contact is in connectors. Makers must follow these rules for safety and work well.

Emission Regulations

Emission rules change how car connectors work. Governments set strict rules to fight pollution. Connectors must manage power well and cut emissions. The Global Automotive Connector Standards help meet country rules, pushing makers to create cleaner connectors.

Effects on the Car Industry

Making and Designing

Changes in How Things Are Made

Car connectors are changing. This makes factories change too. They use robots and machines to make things faster and better. This helps reduce mistakes and makes good products.

Costs Involved

Making costs differ by place. Asia Pacific is cheaper because of low-cost workers and materials. It’s a big spot for car parts. But companies must keep quality high even if it costs more at first. Using tech can cost more now but saves money later by being efficient.

Chances in the Market

New Markets Growing

New places have big chances for growth. More people want fancy cars, especially in Asia Pacific. This area has better factories and sells a lot abroad. Companies can grow by making stuff that fits local needs.

Competition Among Companies

Companies need new ideas to compete well. Those working with European and US car makers must follow many rules. Offering flexible connectors that fit different rules helps them win over others. The global market has problems like supply issues, but being smart and creative leads to success.

"Being smart and creative helps succeed in the changing car connector world." — Experts say

These effects show why planning smartly and using tech is important to stay ahead in the car industry.

The car connector market is changing fast. Electric and hybrid cars, ADAS, and fast data needs are key trends. These focus on making connectors smaller, lighter, strong, and reliable.

"Electric cars push for better connectors."

In the future, new ideas will change car connectors more. Companies must keep up and create new things to stay ahead in this busy market.

See Also

Exploring the Fundamentals of HSD Connectors in Automotive

Understanding the Significance of Fakra Connectors in Modern Cars

Recognizing the Value of Fakra Connectors in Auto Sector