Exploring Trends in Automotive Wiring Connector Types

Car wiring connectors are changing fast, especially with the emergence of various automotive electrical connectors types. They need to work better and last longer in today's cars. These connectors help send power and data between car parts. With electric cars and smart driving systems becoming popular, knowing about new connectors is important. The market for these connectors will grow significantly by 2030, reaching millions in sales. This growth highlights the importance of understanding the latest trends in automotive electrical connectors types to ensure cars remain modern with new technology.

Current Challenges

Getting Parts

Problems with getting connectors

Car makers have trouble getting connectors because of supply chain problems. Things like not enough raw materials and shipping issues make it hard to get these parts. Companies must solve these problems to keep making cars. The cost of metals and plastics affects connector prices. This means companies have to change their prices often.

World events affecting production

Big world events, like pandemics or political fights, can mess up car production and delay shipments. These events cause less space for shipping and more competition for resources. This can slow down car making, delaying delivery to buyers. Car makers need backup plans to handle these risks and keep making cars on time.

Environmental Rules

Following new green rules

Car companies must follow strict green rules about the materials in connectors. These rules aim to lessen harm from making and using cars. To follow them, companies must research how to make good connectors that meet these rules.

Picking eco-friendly materials is hard

Choosing materials that are strong, work well, and are eco-friendly is tough for car makers. Connectors need to last in tough conditions but also be good for the planet. This needs smart designs and new materials that can handle bad weather. Companies are working on fast connectors for smarter cars, pushing the need for green solutions.

Technological Advancements

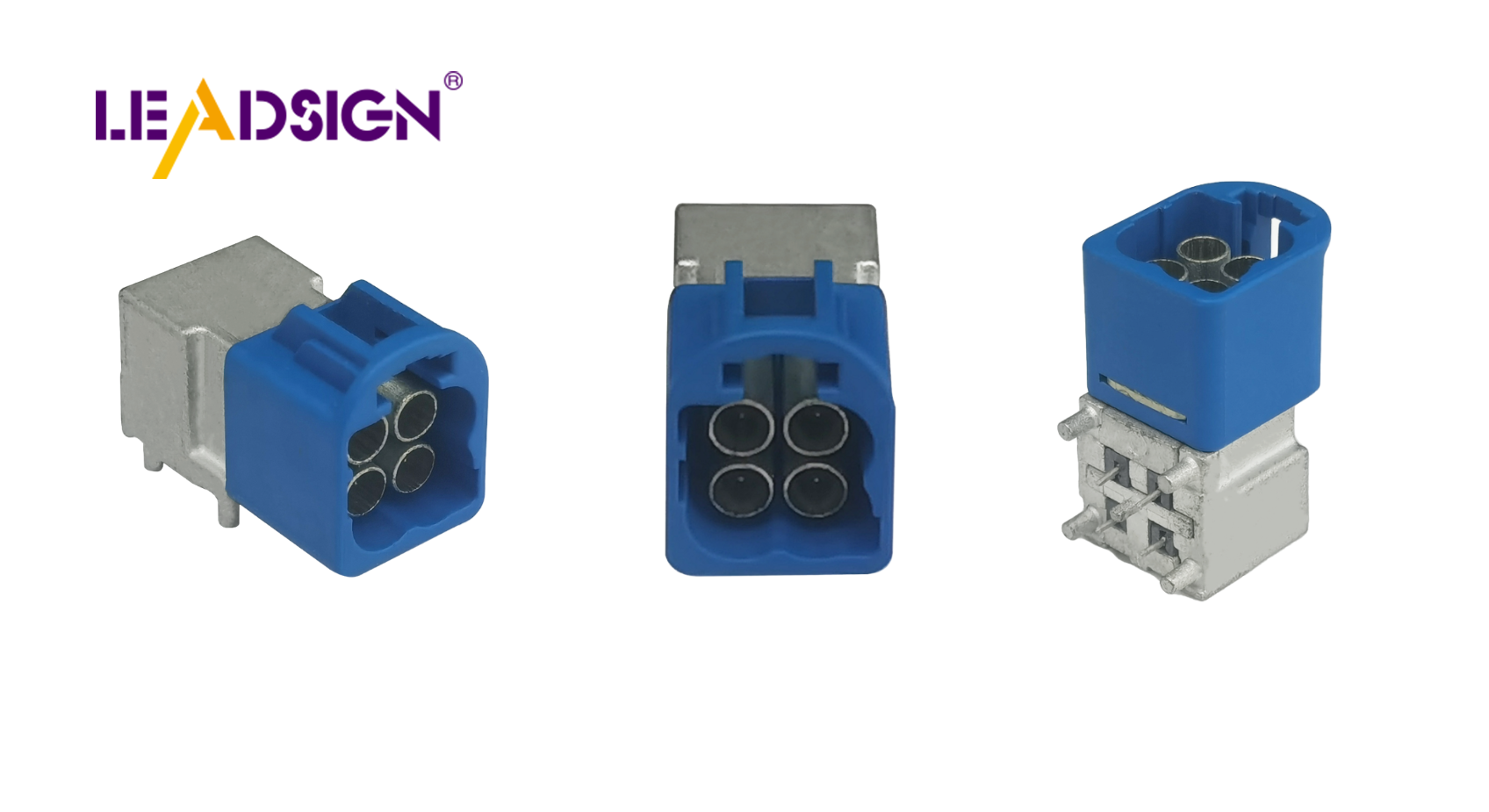

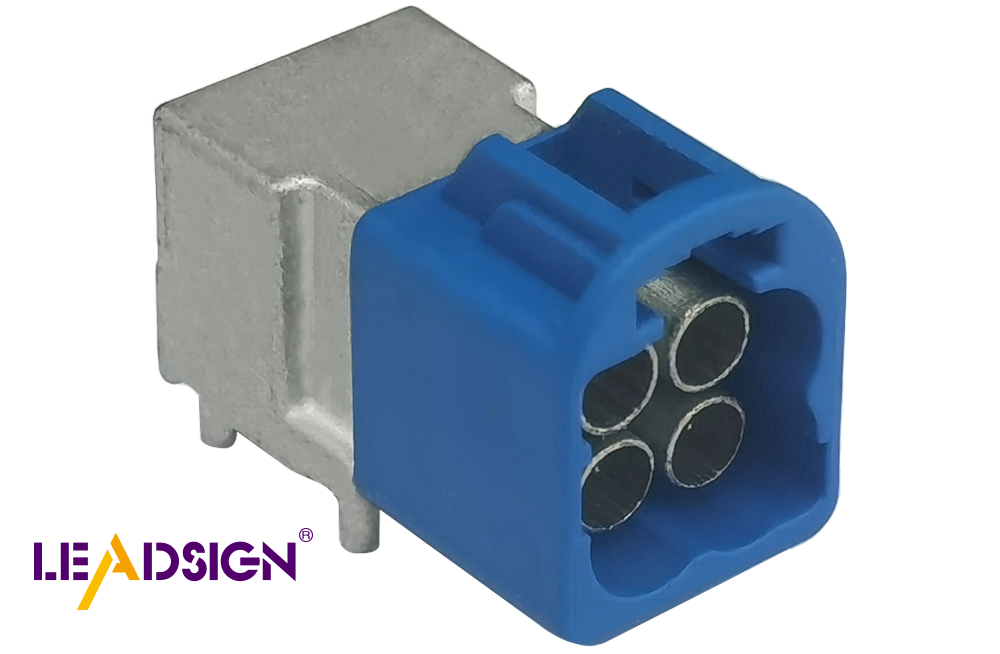

New Connector Types

Car connectors are changing a lot. Engineers make them smaller and better. These tiny connectors fit in tight spaces but still work well. This helps them fit into new cars where space is limited.

Innovations in connector design

New materials and ways to make things help create cool connector designs. These designs make car connectors work better and last longer. Using strong materials, makers build connectors that handle tough conditions and keep working for a long time. This is important as cars get more complex and need good connections to work right.

Enhanced durability and performance

Connectors must be strong and perform well in cars. Cars need fast data links, so new connectors have higher speeds. They keep signals clear, which is key for smooth car operations. So, the car industry spends a lot on making strong connectors that last daily use while working well.

Applications in ADAS and Infotainment Systems

Car connectors do more than just connect parts. They are key in smart driving aids (ADAS) and fun tech systems. These systems need fast data flow, so choosing the right connectors matters.

Role of connectors in advanced driver-assistance systems

In ADAS, connectors send data between sensors and controls. This data helps with features like cruise control or lane-keeping help. Reliable connectors make sure these systems run smoothly, giving drivers safety and ease.

Integration with modern infotainment technologies

Modern fun tech needs to link up with many car parts easily. Car connectors help by providing solid links for sound, video, and data sharing. They support fast data speeds so passengers enjoy great multimedia experiences. As cars get smarter, the need for top-notch infotainment system connectors grows.

Market Trends

Change from Old to New Connectors

Cars are using new connectors instead of old ones. This change happens for many reasons:

Why the change is happening

More Complexity: New cars, like electric ones, need connectors for tricky jobs. Old connectors can't always do this well.

Better Reliability Needed: Electric car connectors must be very reliable. They handle more electricity, so they need good insulation and protection.

New Features: Smart connectors have sensors and can check themselves. They help watch and fix problems before they happen.

Space and Weight Saving: Small connectors work well even if they're tiny. They make cars lighter and save fuel, unlike big old connectors.

Advantages of new over old connectors

Better Data Transfer: New connectors send data fast and resist interference. This helps car parts talk quickly, making cars safer and better.

Improved Car Efficiency: Smaller, lighter new connectors help cars use less fuel and work better overall.

Predictive Maintenance: Smart features in new connectors help fix things early, keeping cars running longer without stopping often.

How Fast Industries Use Them

Different vehicles use new connectors at different speeds based on needs:

Adoption trends in various vehicle types

Electric Cars (EVs): EVs use new connectors a lot because they need strong power links for high voltage.

Luxury Cars: Fancy cars have cool tech needing fast smart connectors for entertainment systems.

Work Vehicles: These take time to switch but are starting to use new ones to be more reliable with less fixing needed.

Effects on Making Cars

Standardization: Using new connectors makes car building more uniform across brands, helping parts fit together well.

Innovation in Making Methods: Companies try new ways to make these advanced parts using machines that work precisely for good quality.

Cost Effects: At first, using new parts costs more but saves money later by making cars run better with fewer repairs.

Future Outlook

Predicting Upcoming Trends

New tech in connector design

Car makers always look for better ways to make cars safer and work well. New connector designs are very important for this change. Engineers work on connectors that send data faster and last longer. These new connectors help car parts talk even in bad weather.

"The patent application identifies problems in wire harness and provides solutions as listed below." - SciTech Patent Art

This shows how people try to fix wiring issues. By using new materials, companies want connectors that are good now and ready for the future.

How it affects the car world

New connector tech will change cars a lot. Cars with these connectors will be safer, run better, and use less fuel. Car makers must change how they build cars to use these new parts.

Also, using smart connectors will lead to new car models with cool features. This will make car companies compete more to sell the best high-tech cars.

Innovations on the Horizon

Future materials and technologies

The future of car connectors is about finding new stuff and ideas. Scientists look at light, green materials that handle heat and shaking well. These help connectors work better and make cars greener.

Smart tech in connectors is coming too. Smart ones can check themselves and give info to car systems right away. This helps fix things before they break, making cars more reliable.

Changes in industry rules expected

As new stuff comes out, rules for car connectors will change too. Groups might set rules so all advanced connectors fit different cars safely. Makers need to know these changes and adjust their methods.

Using standard connectors makes building cars easier and cheaper. It also helps people fix their high-tech cars without trouble.

In short, the future of car wiring promises big changes that will reshape everything. By using new tech and following rules, makers keep their cars cutting-edge.

This blog talked about changes in car wiring connectors. It showed the problems, new tech, and market changes in this area. Knowing these changes helps cars work well. As cars get smarter, good connectors are very important for better performance and safety. Companies making connectors need to spend on research to keep up. Learning about future connector changes will help the car industry grow everywhere.

See Also

Understanding How Fakra Connectors Enhance Vehicle Performance

An Introduction to HSD Connectors for Cars

Enhancing Vehicle Data Transfer with Advanced Connectors