Top-Rated Wire Connectors Automotive Type for 2024

Choosing the right wire connectors automotive type is crucial. They must withstand harsh conditions and maintain a secure connection. Durable connectors have a longer lifespan and resist damage over time. A proper fit ensures they align seamlessly with your car's wiring. Reliable connectors stabilize connections and prevent electrical issues. By considering these factors, you can make informed choices and enhance your vehicle's performance.

Key Takeaways

Choosing the right wire connectors is essential for ensuring durability and performance in automotive applications.

Consider the environment: select connectors that are waterproof or heat-resistant based on your vehicle's needs.

For heavy-duty applications, opt for connectors like Anderson Connectors that can handle high electrical loads and rough conditions.

Budget-friendly options, such as the Napa Primary Wire Terminal/Connector Assortment, provide reliable performance without breaking the bank.

Always match the connector type and size to your car's wiring to avoid electrical issues and ensure safety.

Utilize proper tools like wire strippers and crimping tools to ensure secure and effective connections.

Regularly inspect connectors for wear and tear, and replace them as needed to maintain optimal vehicle performance.

Best Wire Connectors Automotive Type for 2024

Best Overall Wire Connector

The best wire connector should work well and be easy. The Ticonn Solder Seal Wire Connector is a great option. It uses strong materials and is simple to use. This connector keeps wires secure and lasts a long time. Its solder seal design helps electricity flow and stops rusting. You can use it for both big jobs or small car wiring fixes.

Most Durable Wire Connector

Strong connectors are important for tough environments. Anderson Connectors are very sturdy. They handle heavy electrical loads without breaking down. Their strong lock keeps wires connected in rough conditions. These connectors are perfect for off-road cars or big machines. They stay reliable even when used under hard stress.

Best Waterproof Wire Connector

Waterproof connectors protect wires from rain or wet places. The AutoEC 352PCS Electrical Connectors kit works really well here. These connectors have heat-shrink tubes with glue inside to block water. This keeps wires safe from water damage or rusting. The kit has many sizes, so it fits different needs easily. Use them confidently in boats, outdoor areas, or wet spots.

Best Budget-Friendly Wire Connector

Finding a good and cheap wire connector is hard. The Napa Primary Wire Terminal/Connector Assortment is a great choice. This kit has many connectors for different car wiring jobs. Use it for small fixes or big projects without spending too much. These connectors are strong and last longer than other cheap ones. They are easy to install, even if you're new to this. If you want something affordable and reliable, try this kit.

Best High-Performance Wire Connector for Heavy-Duty Applications

Heavy-duty work needs tough connectors for harsh conditions. Anderson Connectors are perfect for these tasks. They handle big electrical loads, great for off-road cars or machines. Their strong lock keeps wires connected in shaky places. You can trust them to work well under pressure. Their strength makes them the best pick for heavy-duty jobs.

Innovative High-Speed Wire Connector for Advanced Applications

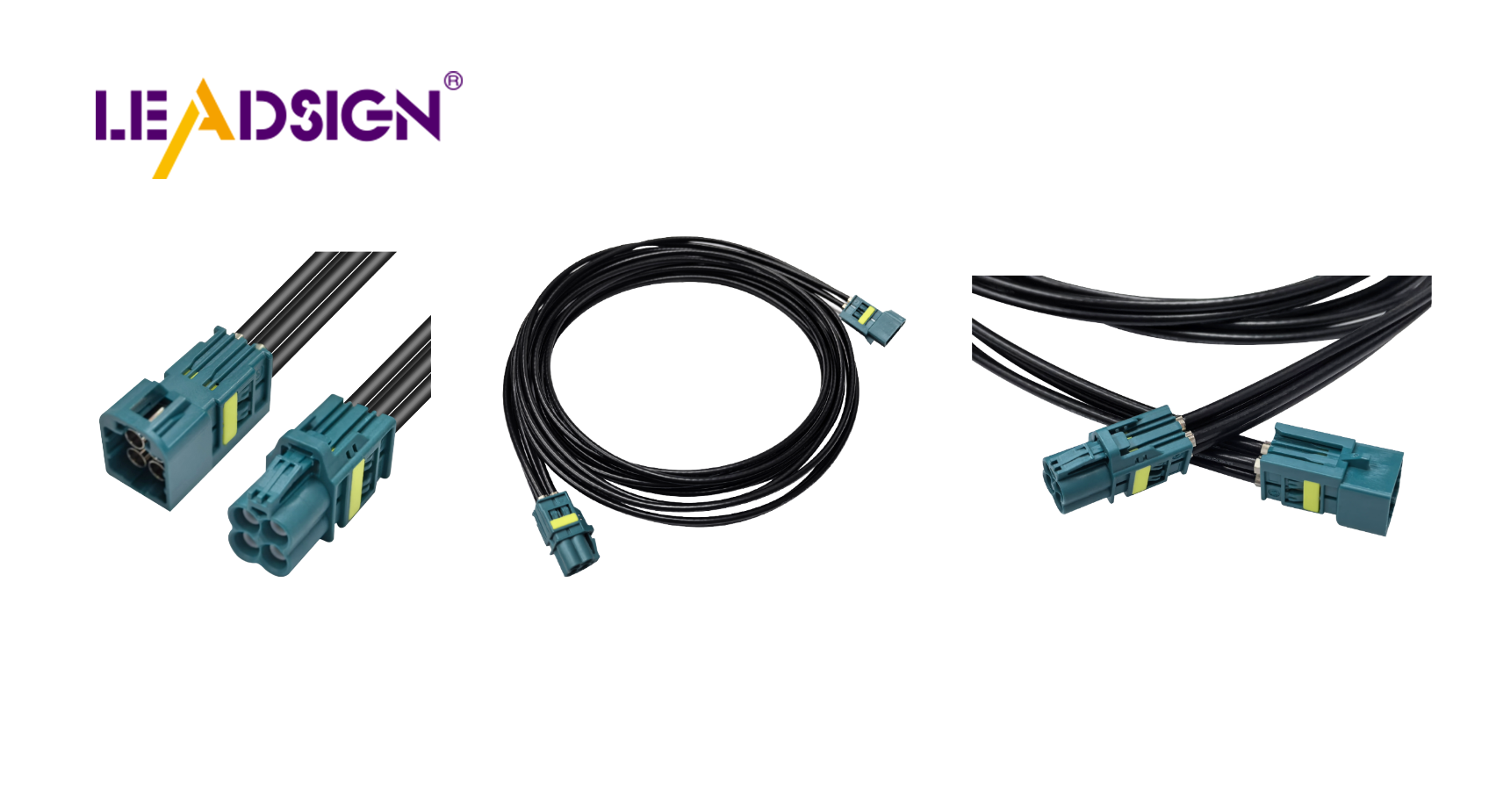

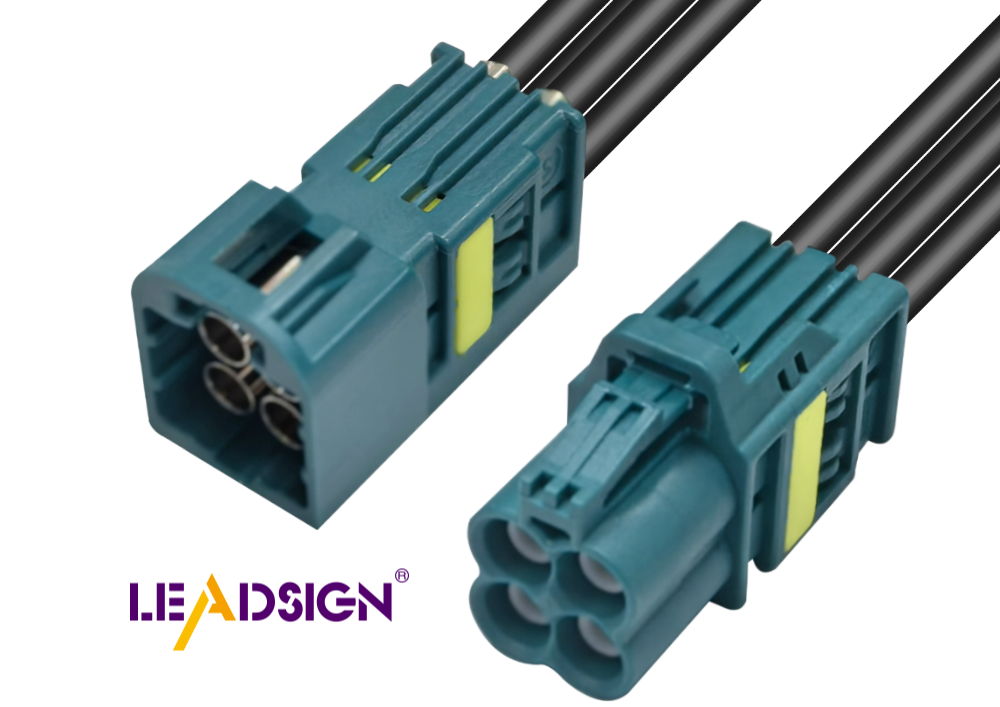

Example: LEADSIGN Mini FAKRA Connector

The LEADSIGN Mini FAKRA Connector shows how future car tech works. It’s small but powerful with cool features for modern cars. Its tiny size fits tight spaces, saving lots of room compared to old connectors.

Features: Fast data speed, small size, smart design

This connector sends data super fast at up to 28 Gbps, great for real-time use. Its smart design saves space but stays strong and sturdy. It works at frequencies up to 20 GHz, making it reliable in high-tech car systems.

Applications: Self-driving cars, entertainment systems, maps

Use this connector in advanced things like self-driving cars or entertainment systems. It also works with navigation and driver help tools. Its speed and versatility make it a must-have in modern car setups.

Buying Guide: Picking the Best Automotive Wire Connectors

Picking the right wire connectors can seem confusing at first. There are many choices, but knowing what to check helps a lot. This guide explains important factors, connector types, and common errors to avoid.

Important Things to Think About

Strength: Materials and Quality

Strong connectors work better and last longer in tough conditions. Look for materials like nylon or thermoplastic elastomers. These materials resist damage and handle heat or cold well. A strong connector means fewer replacements over time.

Fit: Matching Connectors to Your Car

Not all connectors work with every car's wiring system. Check your car’s wire size and power needs before buying. Using the wrong connector can cause problems or damage your car’s wires. Always double-check details before choosing one.

Safety: Secure Connections Matter

Safety is very important when picking connectors. Good connectors prevent electrical problems and keep things safe. Choose ones with locks or heat-shrink features for extra security. These features stop moisture and keep wires stable.

Types of Wire Connectors

Crimp Connectors

Crimp connectors are simple to use with a crimping tool. They create a tight hold on wires and work for most jobs. These are great when you need quick fixes.

Solder Connectors

Solder connectors give stronger connections using melted solder for bonding wires. They are best for high-performance tasks needing steady electricity flow.

Quick-Disconnect Connectors

Quick-disconnect connectors let you remove wires easily when needed often. They save time during repairs or upgrades by making changes faster.

Heat-Shrink Connectors

Heat-shrink connectors protect against water, rust, or rough weather conditions. Heating them seals the connection tightly, keeping it safe outdoors or in wet places.

Mistakes You Should Avoid

Ignoring Weather Conditions (e.g., rain, heat)

Not thinking about weather can ruin your connector choice fast! Pick ones made for rain, heat, or shaking if needed.

Picking Wrong Size or Type of Connector

Wrong-sized connectors make loose wires that don’t work well together! Match sizes carefully with your wire thickness and job type always.

By learning these tips about strength, fit, safety types, plus avoiding mistakes above—you’ll pick great automotive wire connectors easily!

Frequently Asked Questions (FAQs)

Are all automotive wire connectors waterproof?

No, not every automotive wire connector is waterproof. Some are made only for dry areas and won't stop water. For wet or humid places, pick connectors labeled as waterproof. These often have heat-shrink tubes or seals to block water. This helps protect wires from rust or damage. Always read the product details to check if it fits your needs.

How do I ensure a secure connection with my wire connectors?

Follow these steps for a strong connection:

Pick the Right Connector: Match the connector to your wire size and task. Wrong sizes can cause loose connections.

Prepare Wires Well: Strip insulation gently without cutting the wire strands. Clean ends to remove dirt.

Use Proper Tools: Use crimpers or soldering tools for firm attachment. Avoid using random tools.

Test Your Work: Tug wires lightly after connecting to check tightness and stability.

Add Protection: Cover connections with heat-shrink tubing or tape for safety and durability.

These steps help make reliable, long-lasting connections.

What are the best wire connectors for high-temperature environments?

For hot areas, use connectors made of heat-resistant materials. They won’t melt or break in high temperatures. Good choices include:

Heat-Shrink Connectors: These shrink tightly when heated, protecting wires well.

Solder Connectors: Solder bonds stay strong under extreme heat, keeping electricity steady.

Nylon or Thermoplastic Connectors: These materials resist heat and last in tough conditions.

Always check the temperature limit of a connector before buying it to ensure it works for your job's heat levels.

Can I reuse wire connectors, or should I replace them every time?

You might ask if reusing wire connectors is okay. The answer depends on the connector type and its condition. Some are made for one-time use, while others can be reused carefully.

Single-Use Connectors

Some connectors, like solder or heat-shrink ones, can't be reused. These create a strong bond when installed. Removing them often breaks the connector or wire, making it unsafe. Always replace these to keep connections secure and safe.

Reusable Connectors

Connectors like quick-disconnect or Anderson types are reusable. They let you reconnect wires without breaking parts. Check these for rust, cracks, or damage before using again. If they look worn out, replace them to avoid problems.

Best Practices

Inspect Before Reuse: Look for damage like rust or loose parts.

Follow Manufacturer Guidelines: Read instructions about reusing specific connectors.

Prioritize Safety: If unsure about a connector's condition, replace it instead.

Knowing your connector type and checking its state helps decide whether to reuse or replace it for better performance.

What tools do I need to install automotive wire connectors?

Using the right tools makes installing automotive wire connectors easier and safer. Here’s what you’ll need:

1. Wire Strippers

Wire strippers remove insulation without cutting wires inside. Pick one that matches your wire size for clean results.

2. Crimping Tool

A crimper secures crimp connectors tightly onto wires. Choose an adjustable one for different sizes of connectors.

3. Heat Gun

Heat guns shrink tubing around wires evenly and safely. Avoid flames as they can ruin wires or connectors.

4. Soldering Iron

Soldering irons melt solder to join wires firmly together. Use one with temperature control for better accuracy.

5. Multimeter

Multimeters test if connections work properly after setup by checking circuits.

6. Electrical Tape/Heat-Shrink Tubing

These protect wires from water and damage after connecting them securely.

7. Screwdrivers and Pliers

These help tighten screws and hold wires during installation easily.

Tips for Using Tools

Practice Proper Technique: Learn how each tool works to avoid mistakes.

Keep Tools in Good Shape: Clean tools often so they last longer.

Organize Your Space: Arrange everything neatly before starting work.

With these tools and tips, you can connect automotive wiring easily and reliably!

Picking the best wire connectors helps your car work better. The top choices for 2024 are strong, waterproof, and fast. Choose connectors that fit your car’s needs and stay secure. Use the guide to make picking easier and faster. Check out the suggested products to find what works best. Share tips and ideas with others to help them decide too. Start now and improve your car wiring with ease!

See Also

Benefits of HFM Connectors for Automotive Applications

Significance of FAKRA Connectors in Automotive Use

Crucial Role of Fakra Connectors in Today's Vehicles