Top Trends Shaping Auto Harness Connectors This Year

Car harness connectors are important parts of modern cars. They help different systems in the car talk to each other. These connectors send signals to control things like brakes and steering. This makes cars safer and work better. New car technology has created lighter wiring harnesses. These save fuel and lower pollution.

Year | Market Size (USD Billion) | CAGR (%) | Market Share (Asia-Pacific) | Revenue (Asia-Pacific) (USD Billion) |

|---|---|---|---|---|

2023 | N/A | 47.3% | 23.93 | |

2033 | 75.6 | 4.10% | N/A | N/A |

More people want smarter car technology. This pushes car harness connectors to improve. These changes help cars stay safe and work well today.

Key Takeaways

Universal connectors make car building easier. They let different car models share parts, cutting costs and saving time.

Lightweight wire harnesses help cars use less energy. This is great for electric cars, making them run better and save fuel.

5G technology makes cars connect faster. It helps with safety, maps, and fixing problems quickly.

New Trends in Car Harness Connectors

Universal connectors for all vehicle types

Cars today come in many shapes and sizes. Universal connectors are now very important. They help different car models use the same parts. This makes building cars cheaper and easier. For example, .pro, .mini, and .tiny connectors are popular. Each type works for specific car parts like seats or dashboards.

Connector Type | Used For | Rules Followed | Power Limit | Data Speed |

|---|---|---|---|---|

.pro | Seats, heavy equipment | ECE R17 | Up to 400W | Ethernet T1 |

.mini | Dashboards, control systems | N/A | Up to 400W | Ethernet T1 |

.tiny | Screens, small controls | N/A | Up to 400W | Ethernet T1 |

These connectors make car systems work better and last longer.

Push-to-seat connectors for faster assembly

Push-to-seat connectors make car assembly quicker and easier. You can connect parts without needing special tools. This saves time and reduces mistakes during production. Car companies can build cars faster and still keep them high quality. For drivers, this means fewer wiring problems and more reliable cars.

Fiber optics for faster data sharing

Fiber optics are changing how cars share information. They send data quickly and reliably between systems. For example, they help cars talk to traffic lights and other vehicles. Fiber optics also improve self-driving features by making decisions faster. They even check road conditions to keep driving safe and smart.

Better car-to-traffic light communication

Car-to-road sign communication

Car-to-car communication

Real-time traffic updates

Improved self-driving controls

Smaller connectors for compact car designs

Smaller cars need smaller connectors to fit tight spaces. Tiny connectors are harder to handle by hand, so machines assemble them. These small parts are delicate and need extra care during production. Even with these challenges, smaller connectors allow sleek car designs. Companies use advanced machines to make sure these connectors work well in your car.

Impact of Electric Vehicles and Sustainability on Automotive Wire Harness

High-voltage connectors for electric vehicle applications

High-voltage connectors are key parts of electric cars. They safely move power between systems. These connectors have parts like covers, pins, and seals. There are two main types: bolt-on and plug-in connectors. Bolt-on connectors are strong and steady. Plug-in connectors are quick to attach and remove. Companies test these connectors to meet safety rules. Tests check insulation, voltage strength, and circuit shielding. For example, shielding tests ensure resistance stays under 10mΩ. These tests make sure the connectors are safe and work well.

Test Type | Purpose |

|---|---|

Voltage Strength Test | Finds weak spots in voltage handling. Tested 100%. |

Insulation Check | Looks for problems with insulation during assembly. |

Circuit Test | Makes sure circuits match after being put together. |

Air Seal Test | Checks if the connector seals properly under air pressure. |

Shielding Test | Measures resistance in the shield. Must be under 10mΩ. |

Eco-friendly materials to meet environmental regulations

Car makers now use greener materials for wire harnesses. These materials help protect the environment. For example, they replace PVC with recyclable plastics like TPE. These changes cut waste and pollution. Some companies even try biodegradable materials to avoid landfills. Using eco-friendly materials meets green laws and helps the planet.

Lightweight designs for improved vehicle energy efficiency

Lighter wire harnesses make cars more energy-efficient. Less weight means better fuel use and performance. Engineers design smarter layouts and use fewer wires. This is especially helpful for electric cars. Lighter harnesses save energy and support electric car growth.

Modular designs for scalability and customization

Modular wire harnesses are made in smaller, easier parts. This makes assembly faster and more accurate. It also reduces mistakes like using the wrong wire colors. Modular designs allow quick changes for different car models. Automation speeds up production and lowers costs. As electric cars grow, modular harnesses help meet new demands.

Technological Advancements in Car Harness Connectors

5G integration for better car connections

5G is changing how cars connect and share data. It helps cars talk to each other and to traffic systems. This makes driving safer and traffic smoother. You can also enjoy faster internet in your car. It improves entertainment, streaming, and navigation. 5G lets cars check for problems in real-time. This means fewer breakdowns and quicker fixes. Self-driving cars use 5G for faster reactions, lowering accident risks. Fleet managers can track and adjust vehicles instantly, whether driven by people or not.

Cooling systems for advanced car electronics

New car electronics, especially in electric cars, need better cooling. Battery cooling systems use air or liquid to stay cool. Liquid cooling works better because it handles heat more efficiently. Special materials, like phase-change ones, help manage heat in extreme weather. Lightweight foam also helps by improving heat flow and blocking moisture. These cooling methods make electric cars safer and more reliable.

Universal connectors for all car models

Universal connectors make it easier to use the same parts in different cars. This helps car makers meet global needs and cut costs. It also speeds up production and ensures cars work well everywhere. For drivers, this means reliable performance no matter where the car is made.

AI and IoT improving car wiring systems

AI and IoT are making car wiring smarter. AI tools design simpler and better wire layouts. Modular designs allow easy changes for different car models. IoT helps monitor and fix problems in real-time. These technologies support electric and self-driving cars, making them more efficient and reliable.

Challenges and Opportunities in the Automotive Wiring Harness Market

Fixing supply chain problems and material shortages

Supply chain issues can slow car production. Companies now use smart ideas to fix this. Moving factories closer reduces shipping delays. Making simpler wire designs also helps. Modular designs make production faster and easier. Automation is important too. It speeds up work and needs fewer workers for big orders.

Fun Fact: A McKinsey study says 90% of supply chain leaders want to move factories closer in three years. This change could improve how fast companies respond to problems.

Cutting costs while keeping quality high

Saving money without losing quality is tricky. Companies find cheaper materials that are still safe. They also make production faster to save time and money. For example, using fewer wires in designs lowers costs but keeps performance strong. Testing makes sure all products are safe and work well.

New chances in growing markets and electric cars

Growing markets bring new chances for companies. More people in Asia-Pacific and Latin America are buying cars. This increases the need for wire harnesses. Electric cars (EVs) need more wires than regular cars. EVs especially need high-voltage wires. This gives companies a big chance to grow and improve.

Factor | What It Means |

|---|---|

More Electric Cars | EVs need extra wiring, especially high-voltage ones, creating more demand. |

Growth in New Markets | More car buyers in developing areas need affordable and mid-range vehicles. |

Teamwork between car makers and tech companies

Working together helps create better products. Car makers and tech companies team up to make advanced wire systems. These systems include smart features like ADAS and IoT. Sharing ideas helps make lighter, smaller, and better harnesses. This teamwork helps cars meet new electric and self-driving needs.

Tip: Teamwork not only creates new ideas but also helps companies stay ahead in a fast-changing market.

The car wiring industry is changing quickly. Big trends for 2025 are:

Smarter connections with IoT and 5G.

Flexible systems that can be scaled easily.

Green materials and better heat control.

Trend | What It Means |

|---|---|

Green materials | Using eco-friendly ways to make products. |

5G technology | Better car connections and faster data sharing. |

Heat control | Improved cooling for advanced car electronics. |

Flexible systems | Easy-to-change designs for different car needs. |

These trends focus on lighter materials, strong EV systems, and smart wires. Cars will become better, safer, and eco-friendlier. As electric cars grow, wiring will help improve technology and the future of driving.

FAQ

What do auto harness connectors do in cars?

Auto harness connectors join car parts together. They help brakes, sensors, and screens work well. This makes cars safer and better to drive.

Why are lightweight wire harnesses useful for electric cars?

Lightweight harnesses use less energy. They make cars run better and help batteries last longer. This is important as more people buy electric cars.

How does 5G make car connections better?

5G shares data faster. It helps with maps, videos, and fixing problems quickly. It also helps self-driving cars talk to roads and other cars.

See Also

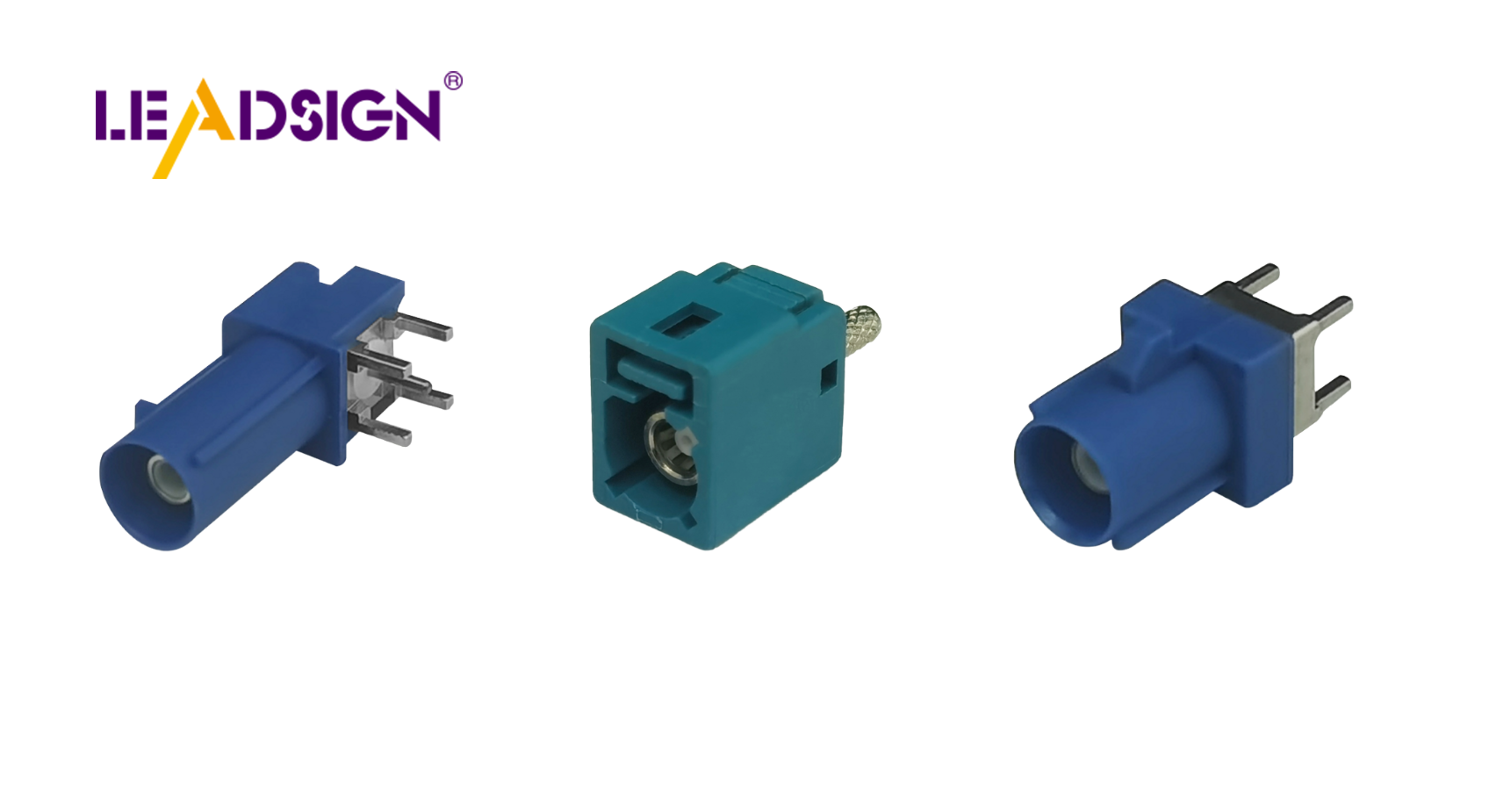

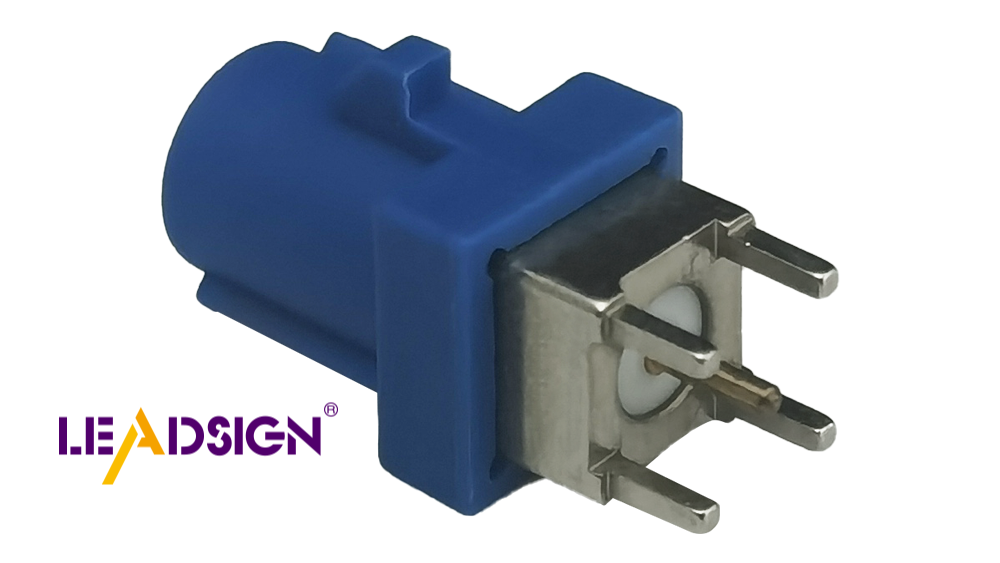

Why Fakra Connectors Are Essential for Today's Vehicles

Exploring High-Speed FAKRA-Mini Connectors in Automotive Applications

Fakra Connectors: A Key Component in Automotive Technology

Benefits of HFM Connectors for Modern Automotive Solutions

High-Speed FAKRA-Mini Connectors: Enhancing Automotive Performance