Top Tips for Using Automotive Electrical Connectors Types

Automotive electrical connectors types are crucial for your vehicle's functionality. They play a vital role in facilitating the transmission of power and signals, ensuring your car operates smoothly. Various connector types serve specific purposes in maintaining robust connections. Understanding these different types enables you to effectively maintain and repair your vehicle. This article provides valuable insights on utilizing these connectors correctly to enhance their longevity and performance.

Understanding Car Electrical Connectors

Knowing car electrical connectors is key for your car's electric system. These connectors make sure power and signals move easily in your car. Let's look at the usual types, materials, and rules for these connectors.

Common Car Electrical Connector Types

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They are common in cars because they are easy to use and work well. They hold tight, making them good for different electric parts in your car.

Ring Connectors

Ring connectors have a round end that goes over bolts or screws. You use them when you need a strong connection. They are great for grounding and battery links, giving a steady electric path.

Butt Connectors

Butt connectors join two wires together. Use them to fix or extend wires. They give a safe connection, stopping any shorts or breaks.

Materials and Build

Metal Types

The metal in connectors changes how well they work and last. Copper is popular because it conducts electricity well. Some might be brass or aluminum, each with special uses.

Insulation Materials

Insulation keeps the connector and wire safe from weather. Plastic and rubber are often used. They bend easily and resist heat and chemicals, making connections last longer.

Connector Ratings and Rules

Voltage Ratings

Voltage ratings show the highest voltage a connector can take. Pick the right ones to stop electric problems. Always check what your car needs for voltage.

Current Ratings

Current ratings tell how much current a connector can handle safely. Choose right ones to keep things working well without overheating.

Industry Standards

Industry standards make sure things fit together safely. Follow these when picking and using connectors for good performance.

Picking the Right Connector

Choosing the right car connectors is important. Think about what your car needs.

Where You'll Use Them

Environment Matters

Think about where you'll use the connectors. If your car faces tough weather, pick strong ones. They should handle heat and wetness well. This keeps them working for a long time.

Power Needs

Know how much power the connectors need to handle. Each type has limits on current and voltage. Pick ones that match your car's power needs. Wrong choices can cause overheating or breaks.

Fit and Size

Connector Size

Check if the connector size fits wires in your car. Too big or small can be bad. Measure wire size and get matching connectors for a snug fit.

Pin Setup

Pin setup must match your car parts. Different types have different pin layouts. Make sure they fit together right to avoid problems.

By thinking about these things, you pick good connectors for your car's needs.

Best Practices for Installation

When you put in car connectors, follow good steps. This makes sure they work well and are safe. Getting ready, using the right way to install, and testing are key.

Preparation and Tools

Before starting, get tools and be safe.

Necessary Tools

You need special tools for car connectors. A wire stripper takes off wire covers without harm. A crimping tool joins wires to connectors tightly. Sometimes a soldering iron is needed too. Keep a multimeter nearby for tests.

Safety Precautions

Safety is very important. Turn off power before touching wires. Wear goggles to keep your eyes safe from sparks or bits flying around. Make sure your area is clean and dry to stop accidents.

Installation Techniques

Right ways of installing help make strong connections.

Crimping Methods

Crimping means pressing a connector onto a wire. Use the right tool for each connector type. Put the wire in the connector and press hard with the tool. This keeps it tight so it won't come loose.

Soldering Techniques

Soldering makes lasting links. Heat up the soldering iron then touch it to where wire meets connector. Add solder until it spreads smoothly over them both. Let it cool still so it's solid.

Testing and Verification

After putting things together, test them to check if they work well.

Continuity Testing

Continuity tests see if electricity can pass through parts joined together. Set multimeter to continuity mode first then touch probes on both ends of connected part; hearing beep shows circuit complete meaning connection good!

Load Testing

Load tests show how much electric load connection handles well enough; link circuit back into its usual power source watching closely whether any overheating happens or not—this checks readiness under real use conditions!

By doing these steps right, your car's electrical parts stay safe longer without problems later on!

Maintenance and Troubleshooting

Keeping car connectors in good shape is important. Check them often to stop big problems and keep things working well.

Regular Inspection

Look at your connectors a lot. This helps find issues early. Watch for damage or rust to keep them working right.

Signs of Wear

See if connectors are broken or cracked. Look for any signs of stress. Bad connectors can make your car's electric parts not work well. Change broken ones fast to stop more trouble.

Corrosion Checks

Rust can hurt how connectors work. Look for green or white powder on them. Clean rusty spots with cleaner and use grease to stop future rust.

Common Issues and Solutions

Knowing common connector problems helps fix them quickly. Fixing these fast keeps your car's electric parts working smoothly.

Loose Connections

Loose connections can make electricity fail sometimes. Make sure all connectors fit tight and safe. If one is loose, tighten it with tools. If it stays loose, change the connector for a better fit.

Overheating Problems

Too much heat can break connectors and cause failures. Look for melting or burn marks near them. Make sure they handle the power they carry well. If heat keeps up, check wires and change bad parts to avoid more harm.

By checking often and fixing usual problems, you keep your car's electric system strong. This way, your car's connectors work best, lowering chances of sudden breakdowns.

Choosing the right car connectors is important. Pick ones that fit your car's needs. Install them properly for strong connections. Check them often to stop problems and make them last longer. Using these tips helps your car work better and stay safe. A good electrical system keeps your car running well. Look at connectors regularly and fix any issues fast. This saves time and stops surprise breakdowns from happening.

See Also

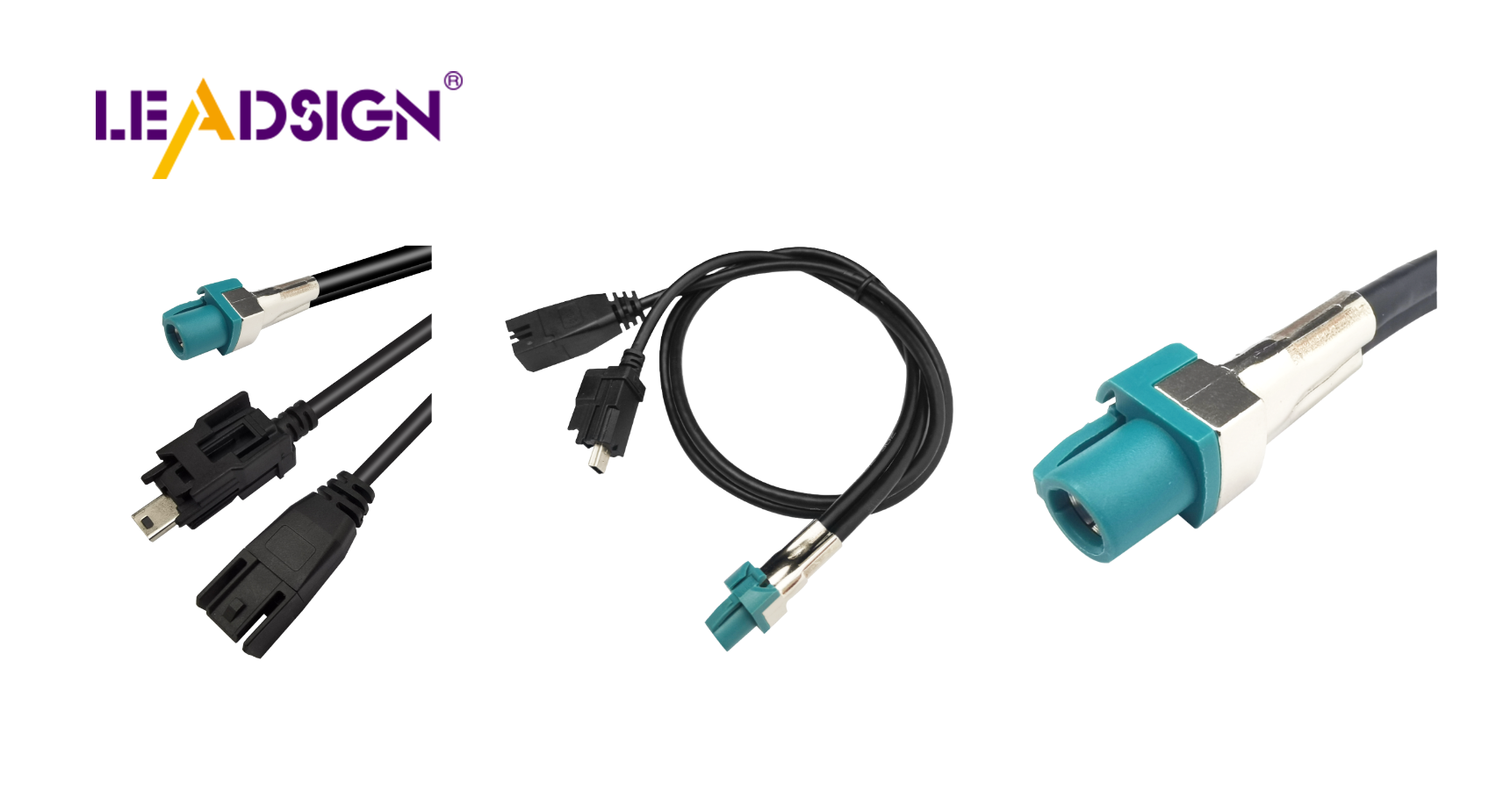

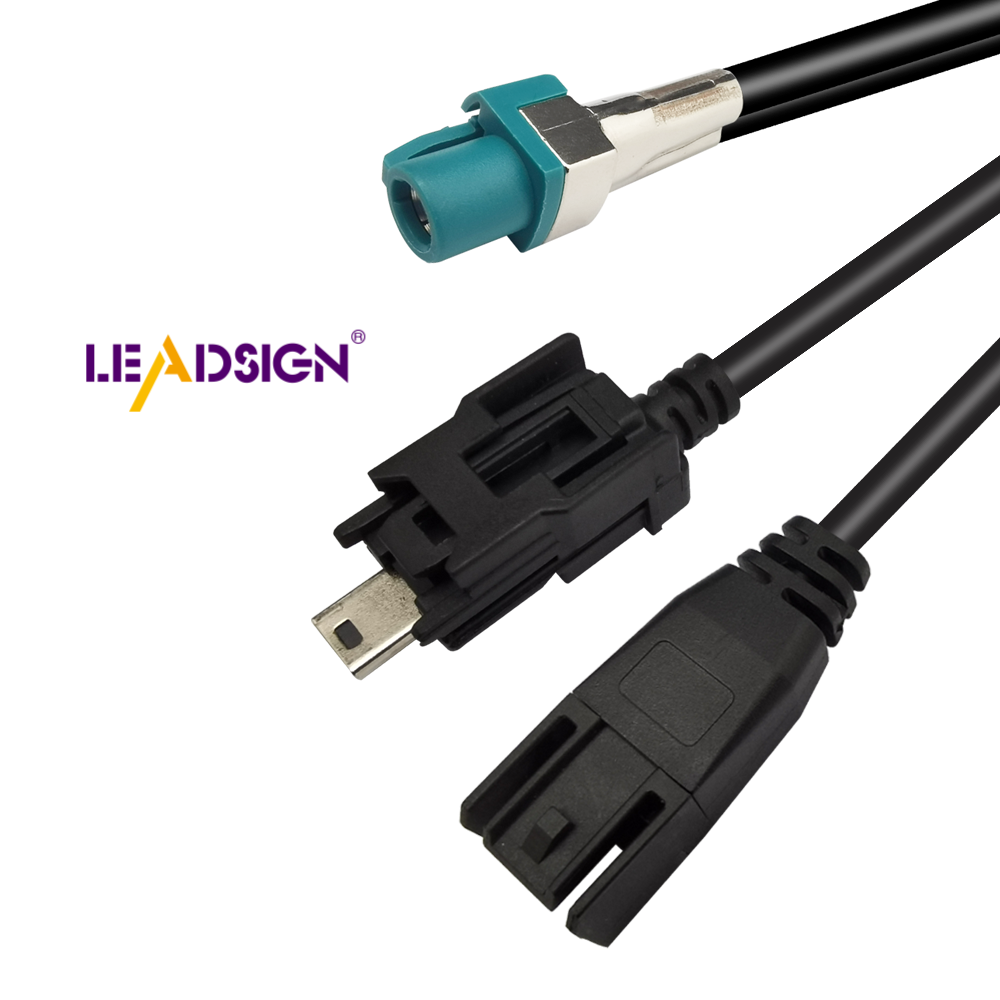

The Significance of FAKRA Connectors in Automotive Usage

Navigating Ford FAKRA Connectors

The Value of FAKRA Auto Connectors in Contemporary Cars

Understanding HSD Connectors in Automotive Sectors

Optimizing Spatial Efficiency: The Strength of Mini FAKRA Connectors in Auto Usage