Top Tips for Car Wire Connector Types

Choosing the right automotive electrical connectors types is crucial for your vehicle's safety and performance. These connectors play a significant role in maintaining the functionality of your car's electrical components. Proper usage of these connectors prevents issues and enhances overall efficiency. Selecting the appropriate connectors safeguards your vehicle from electrical problems. Understanding the various automotive electrical connectors types helps you maintain a robust and well-functioning car system, ultimately extending the lifespan of your vehicle.

Overview of Common Car Wire Connector Types

Knowing different car wire connectors is important. They keep your car's electrical system working well. Each connector type has a job to do. Let's look at some common ones you might see.

Blade Connectors

Blade connectors are very popular in cars. They connect wires to switches or relays. These have a flat metal piece that fits into a slot. They stay connected even if the car shakes a lot. Make sure they fit tightly to avoid problems.

Butt Connectors

Butt connectors join two wires together. They are tube-shaped and link wires end-to-end. Use them to make wires longer or fix broken ones. Strip the wire ends, put them in the connector, and crimp tight for a strong hold.

Ring and Spade Terminals

Ring and spade terminals are handy connectors for cars. Use them to attach wires to screws or studs. The ring is round; the spade looks like a fork with an open end. They're easy to use when you need to take wires off often.

By learning about these connectors, your car's electrical parts will work better and last longer. Regular checks and using them right helps avoid problems.

Quick Disconnects

Quick disconnects make it easy to join and separate wires in your car. Use them when you often need to change parts. They have a male and female end that click together tightly. This keeps the connection strong but lets you take them apart easily.

Make sure quick disconnects fit well. Loose ones can cause electrical problems. Check them often for damage. If damaged, replace right away to keep your car's electrical system safe. Doing this stops issues and keeps your car's electronics working well.

Automotive Electrical Connectors Types

Knowing different automotive electrical connectors is key for your car's performance. Each type has its own job, and using them right helps your car's electric parts work better.

Connector Crimp and Depin Tool: This tool is important for handling automotive connectors types. It helps crimp connectors tight and remove pins if needed. Good tools mean better connections.

Connector and Pigtail Repair Terminal Release Kit: This kit fixes and cares for automotive connectors types. It has what you need to remove terminals safely, keeping connections strong.

Automotive Pigtail Connectors: These are vital for power and data moving between systems in cars today. Clean and check these often to keep them good. Protect from water, heat, and don't tighten too much to keep them lasting long.

By knowing the right automotive connectors types, you can keep a strong electric system in your car. Regular checks help avoid problems and make your car's electronic parts last longer.

Best Practices for Using Connectors

Installation Tips

When putting in car connectors, follow some key tips. First, turn off power before working on wires. This stops shocks and keeps parts safe. Use the right tools like wire strippers and crimpers. They help you cut wires neatly and hold connectors tight.

Strip wire ends well before connecting them. The bare wire should be long enough to connect but not too long to cause problems. After putting in the wire, squeeze the connector hard to keep it secure. A good crimp stops loose wires and failures.

Common Mistakes to Avoid

Avoiding mistakes saves time and trouble. Don't use the wrong connector type for the job. Each one has a special use, so pick what fits your need. For example, use butt connectors to join wires end-to-end and ring terminals for screws.

Another mistake is not checking if connectors fit well. Loose ones can cause electric issues or harm systems. Make sure they fit snugly but don't tighten too much as it can hurt wires.

Maintenance Advice

Regular care of car connectors is important for best work and lasting longer. Check them often for wear or damage signs like rust or broken parts. Fix any problems fast to stop more harm.

Use a plastic-safe cleaner to make connections better by removing dirt. Put a thin layer of grease on pins or sockets to keep out water and rust. This helps them last longer and work well.

Keep connectors dry and clean when storing them to avoid rust or damage. Good storage keeps them ready for future use. Follow these tips to keep your car's electric system running smoothly.

Tools and Accessories

When working with automotive electrical connectors types, having the right tools is key. These tools make your work easier and ensure connections are safe and strong. Let's look at the main tools and accessories you should have.

Essential Tools for Working with Connectors

Wire Strippers: Use wire strippers to take off insulation without harming wires. This tool gives a clean strip, important for a good connection.

Crimping Tools: Crimping tools help attach connectors firmly to wires. A good crimper stops loose connections that can cause problems.

Soldering Iron: For some connectors, soldering makes the best link. A soldering iron creates strong joints, especially where there's lots of movement.

Multimeter: A multimeter checks if electrical connections work right. It helps find any issues in the system.

Connector Crimp and Depin Tool: This tool is crucial for handling different connector types. It helps crimp tightly and remove pins when needed for better links.

Recommended Accessories

Dielectric Grease: Put dielectric grease on connectors to keep out moisture and rust, making them last longer.

Heat Shrink Tubing: Use heat shrink tubing to cover and protect connections from things like water or dust.

Plastic-Safe Contact Cleaner: A contact cleaner clears dirt from connectors, helping them work better by improving conductivity.

Connector and Pigtail Repair Terminal Release Kit: This kit is vital for fixing connectors safely, keeping them strong.

By using these tools and accessories, you can manage your car's electric system well. Regular use avoids common issues and keeps your connectors working their best.

Troubleshooting and Maintenance

Finding Common Problems

Car wire connectors can have common problems. Loose wires often cause electric failures. Look for damage signs like worn-out wires or rusty ends. Rust can stop electricity from flowing, causing parts to break. Overheating is another issue if connectors aren't right for the power they carry. This can melt covers or burn connectors.

Fixes and Care Tips

Keep your car's electrical system good with these tips:

Check Often: Look at your connectors regularly for damage or rust. Finding problems early stops bigger issues.

Clean Up: Use a safe cleaner to get rid of dirt on connectors. This helps them work better by improving electricity flow.

Use Grease: Put a little grease on connection pins or holes to keep water away and stop rust, making them last longer.

Right Tools: Buy good tools like the Connector Crimp and Depin Tool or the Professional Crimp Tool for secure connections and easy care. The Connector Crimp and Depin Tool now costs $39.99, down from $50.00.

Soldering and Wraps: For strong links, use soldering with shrink-wraps. The Solder, Shrink-Wrap Repair Combo (ZLDR-SW) is cheap at $12.99 for a solid connection.

Store Well: Keep connectors dry and clean when storing to avoid rusting so they're ready later.

By using these tips, your car's electric system stays reliable and works well longer with regular care.

Picking the right connectors is key for your car's wires. Right choices keep it safe and working well. Regular checks make sure it lasts longer. Clean connectors stop bad connections and harm. Look at them often to find problems early. Use the correct tools to prevent damage. Don't tighten too much to keep good links. Use special grease to protect from water and rust. Buying good tools helps things work better. By doing these steps, you keep your car's electric system strong and lasting long.

See Also

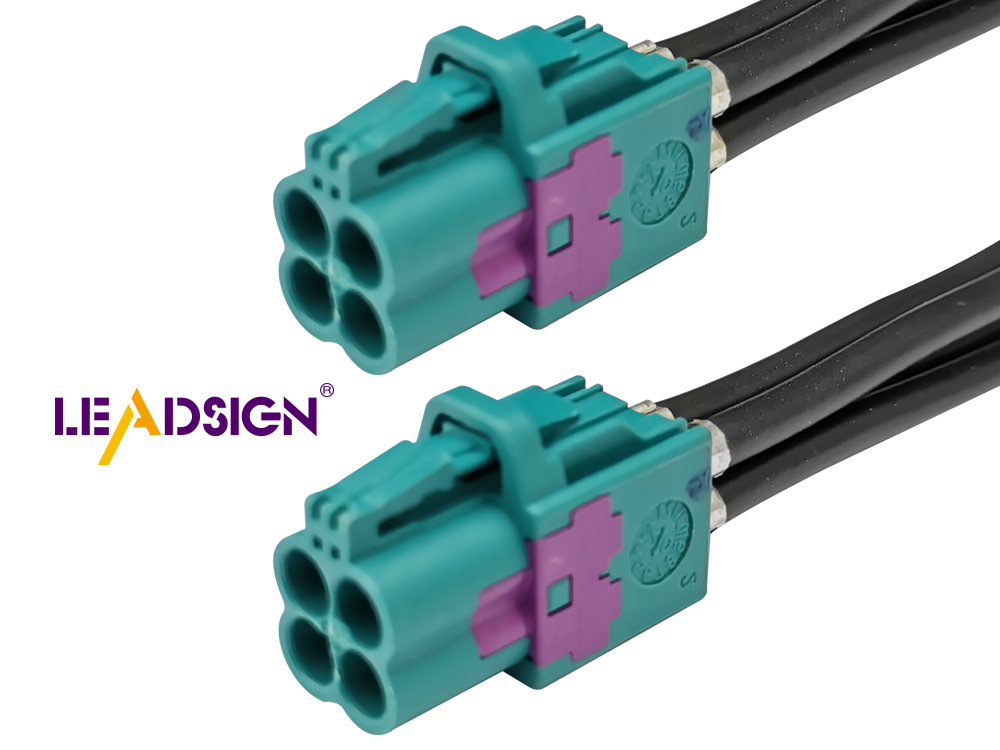

Essential Insights on Fakra Connectors: Types and Uses

Why FAKRA Connectors Matter in Automotive Systems

Significance of FAKRA Z Connectors in Vehicle Technology