Must-Have PCB Board Wire Connectors for Electronics

In electronics, good connections are key to successful projects. PCB board to wire connectors link circuit boards to outside parts easily. These connectors make assembly simple and last longer. They also reduce the need for soldering wires together. Wire-to-board connectors improve signals and keep things stable. This works even in tough conditions. Whether for home gadgets or factory machines, PCB connectors help devices work well and stay reliable for a long time.

Key Takeaways

PCB board-to-wire connectors are essential for linking circuit boards to wires, ensuring reliable power and signal transmission.

Using these connectors simplifies assembly and maintenance, allowing for quick wire connections and easy repairs without soldering.

Different types of connectors, such as header connectors, terminal blocks, and JST connectors, cater to various project needs, offering flexibility in design.

Choosing the right connector involves considering voltage limits, environmental conditions, and compatibility with your project’s specifications.

Investing in high-quality connectors can save money in the long run by reducing repair costs and improving device reliability.

Always check for the availability of replacement parts to ensure smooth project continuity and minimize downtime.

What Are PCB Board-to-Wire Connectors and Why Are They Important?

Definition and Function

What are PCB board-to-wire connectors?

PCB board-to-wire connectors are important parts in electronics. They link a circuit board to wires or cables. This helps send power and signals between the board and other parts. These connectors act like bridges, helping devices work smoothly. From small gadgets to big machines, they keep everything running well.

Expert Insight: Echo Lee, an IoT expert, says that PCB connectors give strong and safe links for sending power or signals.

How do they work in electronics projects?

These connectors make it easy to connect wires to a PCB. Instead of soldering wires directly, you can use these for neat setups. They hold connections steady, even in tight spaces or tough conditions. You can also take apart or fix parts without harming the board. This makes them very useful in modern electronics.

Key Benefits of Using PCB Board-to-Wire Connectors

Improved reliability and durability

PCB connectors are made to last long under stress. They stay strong against shaking, heat changes, and harsh environments. This keeps devices working well for years. For example, car electronics use these connectors to perform steadily even in extreme weather.

Simplified assembly and maintenance

Wire-to-board connectors make building projects faster and easier. You can attach or remove wires quickly without special tools. This saves time and lowers mistakes during setup. If something breaks, you can replace it easily without redoing the whole circuit.

Enhanced compatibility with various components

Board-to-wire connectors come in many shapes and sizes for different needs. Whether your design is simple or complex, you’ll find one that fits perfectly. This flexibility helps create compact designs while connecting all parts properly.

In short, PCB connectors quietly support the devices we rely on daily—from phones to factory machines.

Top Must-Have PCB Board-to-Wire Connectors

Picking the right connectors is very important in electronics. Below are some popular and trusted pcb board to wire connectors. These choices give strong links, easy use, and long-lasting results.

Header Connectors

Features and benefits

Header connectors are useful and common in many devices. They come in single or double rows for different setups. These connectors link the printed circuit board to other parts securely. Their design lets you connect or remove parts without harm.

Some main benefits are:

Small size saves space on the printed circuit board.

Strong build keeps connections steady over time.

Easy to adjust with different pin numbers as needed.

Common applications

Header connectors are found in gadgets, machines, and robots. They work well for projects needing easy part changes or upgrades often.

Pro Tip: Use header connectors for testing or projects needing adjustments often.

Terminal Blocks

Features and benefits

Terminal blocks help attach wires to a printed circuit board without soldering. They have screws that hold wires tightly in place. This makes them simple and dependable to use.

Benefits of terminal blocks include:

Neat wire setup, avoiding mess.

Strong links that handle shaking and tough conditions.

Easy repairs since wires can be replaced simply.

Common applications

These are used in control systems, power units, and smart home devices. They’re great where wires need connecting or removing often.

Did You Know? Terminal blocks handle high power because they carry more current safely.

JST Connectors

Features and benefits

JST connectors are tiny, light, and fit small designs perfectly. They’re known for being reliable and simple to use. These connect wires to the printed circuit board, making them a top choice for engineers.

Key features include:

Compact design saves room on the board.

Locking system stops accidental unplugging.

Works with many wire sizes easily.

Common applications

JST connectors are used in drones, RC toys, and battery-powered tools. Their small size fits portable devices well.

Fun Fact: JST connectors work great for fast data transfer because they stay stable.

Molex Connectors

Features and Benefits

Molex connectors are popular for many electronics projects. They connect wires to a printed circuit board securely. These connectors are strong and flexible, making them useful in many setups. Molex connectors come in different styles like single-row or double-row designs.

Main benefits include:

High-density connections: They connect many wires in small spaces, saving room.

Durability: Built tough to last through wear and tear.

Ease of use: Easy to put together or take apart for repairs.

Common Applications

Molex connectors are used in gadgets, cars, and machines. They work well where strong and steady connections matter most.

Pro Tip: Pick Molex connectors for compact designs that need strength too.

IDC (Insulation Displacement) Connectors

Features and Benefits

IDC connectors make connecting wires quick and simple. They cut through wire insulation to make contact, so no stripping is needed. This makes them great for fast assembly jobs.

Advantages include:

Time-saving installation: Wires connect quickly without extra steps.

Reliable connections: Stay secure even with lots of movement or shaking.

Compatibility: Work well with flat ribbon cables for tight spaces.

Common Applications

IDC connectors are found in phones, computers, and other data devices. They're perfect for small spaces needing neat wiring setups.

Did You Know? IDC connectors are great for Ethernet or USB because they stay stable.

Screw Connectors

Features and Benefits

Screw connectors are simple but effective for connecting wires to boards. Screws hold the wires tightly, creating a strong link.

Key features include:

Strong grip: Screws keep wires firmly connected under pressure.

Flexibility: Fit different wire sizes easily.

Ease of maintenance: Wires can be replaced without breaking the connector.

Common Applications

Screw connectors are used in power systems, control panels, and heavy machines. They're ideal when adjustments or high current handling is needed.

Expert Tip: Use screw connectors for tough jobs needing reliable performance.

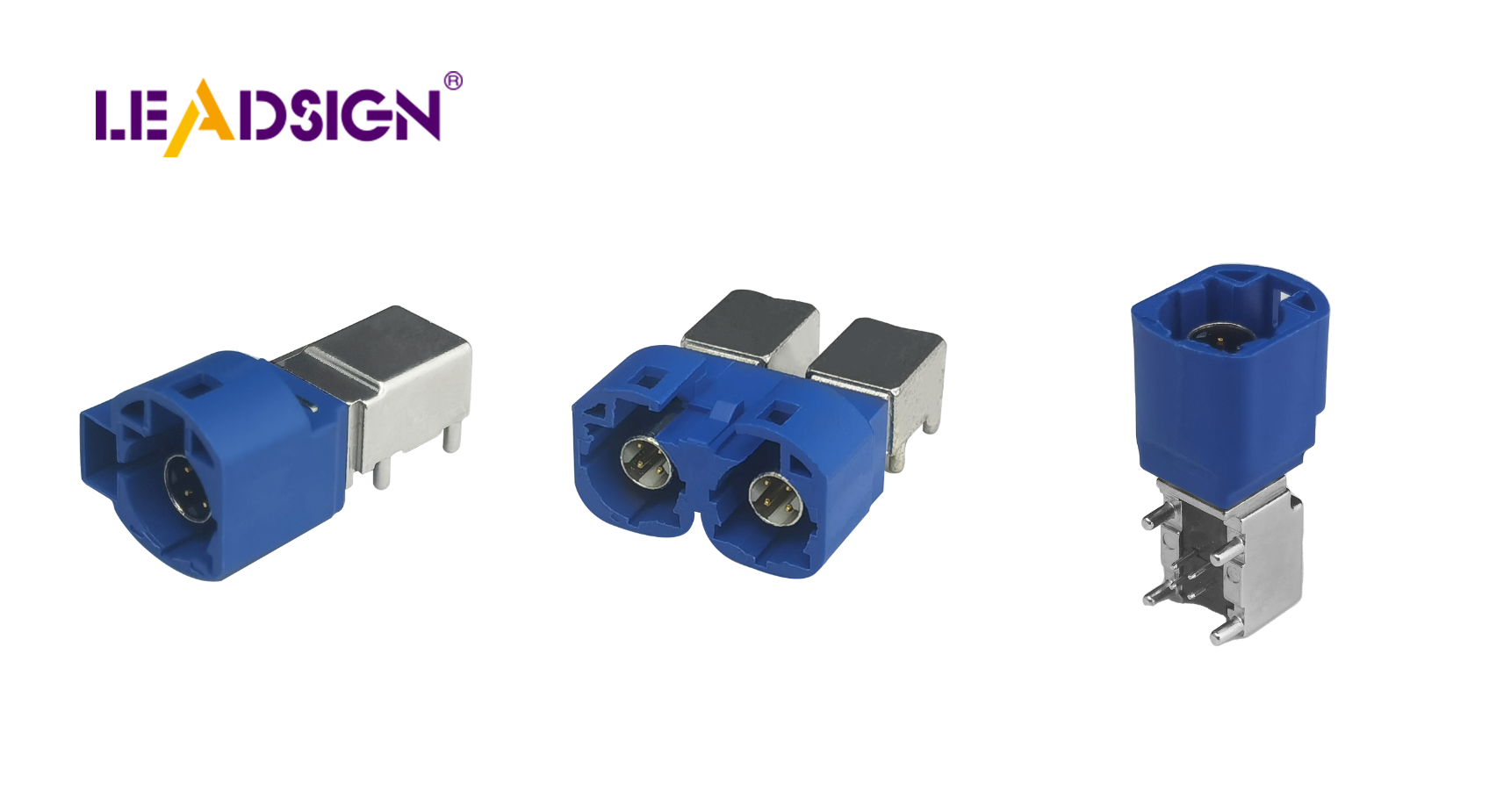

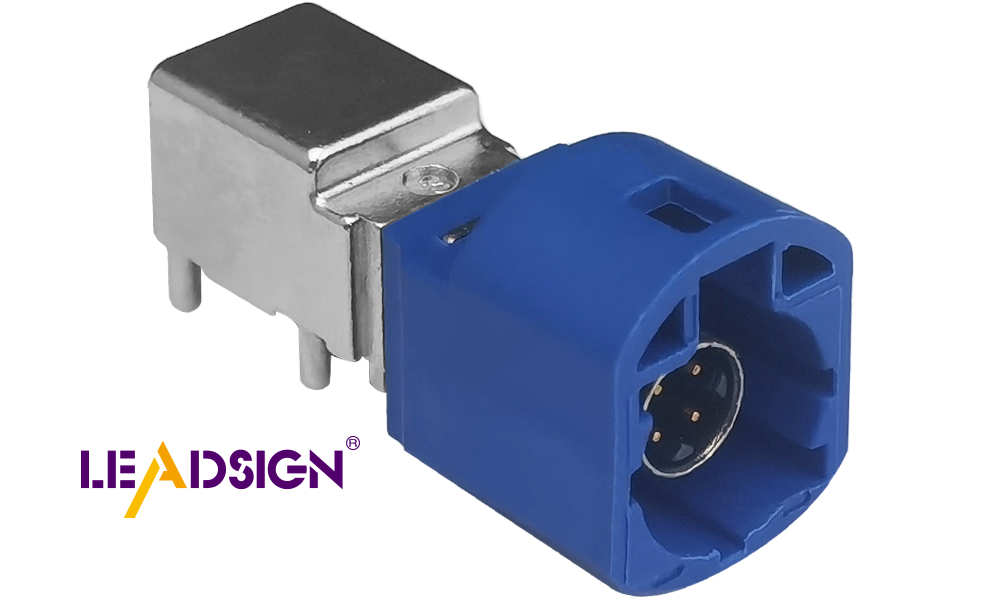

HSD (High-Speed Data) Connectors

Features and Benefits

HSD connectors are great for sending data quickly and reliably. They are made to handle high-speed data, keeping communication smooth between the printed circuit board and other devices. Their strong build makes them perfect for tough conditions where durability matters.

Here’s why HSD connectors are special:

Primary and secondary locks: These locks keep connections tight, avoiding accidental unplugging.

Crimp connection: This creates a steady link, reducing signal problems or interference.

High cable retention force: Cables stay secure even with movement or shaking.

High-density coding efficiency: The plastic case has coding options to prevent wrong connections.

These features make systems more reliable and easier to put together. HSD connectors work well even in hard situations, giving consistent results every time.

Common Applications

HSD connectors are useful in many fields because they send high-speed data so well. Here’s where they’re often used:

Automotive electronics: Great for linking cameras, sensors, and car entertainment systems.

Telecom equipment: Used in radio stations for stable communication signals.

Digital infotainment systems: Perfect for connecting media devices with clear audio and video.

USB and Ethernet connections: Works with USB 1.0, 2.0, 3.0, and Ethernet for fast data transfer.

Industrial networks: Fits digital networks like IEEE 1394 (Firewire) easily.

Pro Tip: If your project needs fast and secure data transfer, use HSD connectors. They handle modern tech demands while staying compact.

Whether you’re designing a car system or telecom device on a printed circuit board, HSD connectors give speed and dependability. Their flexibility makes them a favorite for engineers and hobbyists alike.

How to Pick the Best PCB Board-to-Wire Connector

Choosing the right PCB board-to-wire connector is very important. A wrong pick can cause bad performance or device failure. Here are key things to think about for a smooth project.

Think About Your Project Needs

Voltage and current limits

Check how much voltage and current your project needs. Each connector has a limit, and going over it can cause damage. For high-power projects, use connectors that handle more current safely. Always match the connector’s rating to your device’s needs.

Environment conditions (like heat or moisture)

Consider where your device will be used. Will it face heat, cold, or wet areas? Some connectors work well in tough places, while others are for indoor use only. For outdoor or factory devices, choose ones that resist water, heat, and shaking.

Tip: Use HSD connectors for car electronics as they handle tough jobs and fast data transfer.

Look at Connector Features

Strength and material quality

Strong materials make connectors last longer. Gold-plated contacts or sturdy plastic housings improve durability. For example, Molex connectors are strong and save space on boards with their smart design.

Easy setup and repairs

Pick connectors that are simple to use. Some like IDC connectors install quickly without stripping wires. Others like screw connectors let you replace wires easily without breaking anything. Choose ones that save time during assembly or repairs.

Pro Tip: If you need frequent changes in your project, pick easy-to-use connectors.

Ensure Compatibility

PCB fit and pin setup

Your connector must fit your board perfectly. Check pin spacing and layout carefully before buying. Connectors like header types come in many setups to match different designs.

Wire size and insulation type

Not all wires fit every connector type. Match the wire size (gauge) with the right connector. Small wires work well with JST connectors, while terminal blocks suit thicker wires in power systems. Also, check if the insulation matches for stable connections.

Budget and Availability

Finding the right balance

Picking a PCB board-to-wire connector needs careful thought. Cheaper ones cost less but may break easily. High-quality connectors, like Molex connectors, have smart designs and strong builds. These save space on your printed circuit board and last longer. Spending more upfront can lower repair costs later.

Think about what your project needs. Simple projects might work with cheaper options. For tough jobs or high-speed data transfer, better connectors are worth it. Paying extra now can prevent problems in the future.

Pro Tip: Good connectors save money by avoiding repairs later.

Easy to find replacements

Having replacement parts is very important. Imagine needing a new connector but not finding one in stock. This could delay your work and cause stress. Brands like Molex offer reliable products that are easy to find worldwide.

Check if replacement parts are available before buying. Some connectors let you swap out broken pieces instead of replacing everything. This saves time and money during fixes.

Did You Know? Picking connectors with easy-to-find parts makes repairs quicker and simpler.

By choosing affordable yet available options, you keep your project smooth without losing quality or performance.

Picking the right PCB board-to-wire connectors is very important. This guide covered key types like header connectors, terminal blocks, JST connectors, Molex connectors, IDC connectors, screw connectors, and HSD connectors. Each type has special features for different uses. For instance, HSD connectors are great for fast data transfer in car systems or media devices. By knowing what your project needs and checking for strength, fit, and performance, you can choose connectors that make your circuit board work better and last longer.

FAQ

What do PCB board-to-wire connectors do?

PCB board-to-wire connectors join circuit boards to wires or cables. They help send power and signals smoothly, making them vital for electronics. You’ll see them in everything from home devices to factory machines.

How can I pick the right connector?

To choose a good connector, think about these:

Power needs: Match the voltage and current ratings.

Environment: Check for heat, moisture, or chemical exposure.

Size and pins: Make sure it fits your board design.

Strength: Pick durable materials that last long.

These steps will help you find the perfect connector.

Can one connector work for all projects?

No, every project needs a specific type of connector. For example, HSD connectors are great for fast data transfer. Meanwhile, screw connectors handle strong power systems well. Always match the connector to your project’s needs.

Are PCB connectors reusable?

Yes, most PCB connectors can be reused. You can unplug and reconnect them without damage. This makes them useful for projects needing repairs or changes often.

What’s different between header connectors and terminal blocks?

Header connectors are small and save space on boards. They’re common in gadgets or robots. Terminal blocks use screws to hold wires tightly. They’re better for high-power setups needing frequent wire changes.

Quick Tip: Use headers for small gadgets; use terminals for heavy power jobs.

Do PCB connectors improve signal quality?

Yes, good connectors reduce interference and keep signals stable. For instance, IDC connectors work well in Ethernet or USB devices by keeping signals steady.

How can I tell if a connector is strong?

Look at its material and design features like gold-plated contacts or locks. Brands like Molex or HSD are known for being tough and lasting long.

Can damaged connectors be replaced easily?

Yes, many allow easy replacement without trouble. Brands like Molex have parts available worldwide. Always check compatibility before replacing anything to avoid issues.

Which connector is best for outdoor use?

For outdoor setups, pick ones that resist water, heat, and shaking. HSD connectors, used in cars or telecoms, are great choices here.

Why does pin configuration matter?

Pin setup ensures the connector fits your board properly. A wrong fit can cause bad connections or failure. Always double-check pin spacing before buying one.

Pro Tip: Flexible pin options like header types make designs easier!

See Also

Exploring FAKRA Connectors for Enhanced Automotive PCB Performance

Why FAKRA PCB Connectors Are Essential for Automotive Communication

Key Benefits of FAKRA PCB Mount Connectors in Automotive and RF

Understanding the Benefits of FAKRA Connectors in Automotive Use