Top Automotive Harness Connectors for Heavy-Duty Applications Reviewed

Durable car harness connectors are important for heavy-duty vehicles. They keep the car working and safe with strong electrical links. Tough conditions like shaking, water, and heat changes can harm them. Picking the right connectors makes cars work better and safer. This helps drivers stay safe in hard driving conditions.

Key Takeaways

Pick strong connectors for safety in heavy-duty vehicles. Tough connectors handle heat, water, and vibrations well.

Choose connectors by their materials and design. Find ones made of copper alloys and sturdy plastics for better use and longer life.

Look for certifications like RoHS and WEEE. These prove the connectors are safe and good for the environment.

Overview of Automotive Harness Connectors

Role of Harness Connectors in Heavy-Duty Vehicles

Harness connectors are key to keeping big vehicles safe. They help electrical parts, like lights and sensors, work together. Without them, the vehicle's electrical system would not work well.

Here’s a simple look at what they do:

Function | Description |

|---|---|

Internal connectivity | Links inside parts like radios and sensors. |

External connectivity | Lets mechanics use tools to check for problems. |

Replacement | Helps swap out parts without stopping the vehicle. |

These connectors make the vehicle's electrical system work better and safer.

Common Applications in Heavy-Duty Scenarios

Harness connectors are used in many heavy-duty machines. You’ll see them in farm tools, trucks, and building equipment. They power GPS, control lifts, and manage smart systems. They are strong enough to handle tough jobs.

For example, in building machines, they connect sensors to check engines. In farm tools, they link GPS for accurate farming. These uses show how they keep machines working and safe.

Importance of Reliability in Electrical Systems

Good connectors are very important for heavy-duty vehicles. These vehicles face heat, shaking, and wet conditions. If the electrical system fails, it can cause delays or accidents. Strong connectors keep things running smoothly.

Choosing connectors made from tough materials helps a lot. They make the vehicle safer and improve how well it works.

Key Factors That Affect How Long Connectors Last

Challenges from the Environment (Heat, Water, Rust)

The environment can greatly affect how long connectors last. Very hot or cold temperatures can damage insulation and cause failures. This might even lead to fires in extreme cases. Water or moisture can get inside connectors, causing rust or short circuits. For example, connectors near salty water need special coatings to stop rust. In hot areas, connectors need materials that can handle high heat without breaking down.

Always think about where the connectors will be used. Picking the right type for the environment helps them last longer and work better.

Stress from Use (Shaking, Wear and Tear)

Heavy-duty vehicles deal with a lot of shaking and stress. These movements can loosen connectors, making them work poorly. Over time, parts that rub together wear out and lose strength. This wear increases resistance, which creates heat and can stop connections from working.

Shaking can harm connectors and shorten their life.

Rubbing parts wear out and lower efficiency.

More resistance from wear can cause overheating and failures.

To prevent these problems, choose connectors built to handle shaking and stress well.

Materials and Design Matter

The materials and design of connectors decide how strong they are. Good metals like copper alloys conduct electricity well and resist rust. Special plastics like PEEK handle heat and chemicals, making them great for tough jobs. Coatings like gold plating stop rust and keep connections stable.

Feature | What It Does |

|---|---|

Material Choice | Strong metals like copper alloys resist rust and conduct electricity well. |

Insulation Materials | Plastics like PEEK handle heat and chemicals for tough uses. |

Surface Coating | Gold plating stops rust and keeps connections steady. |

Better Design | Multi-point contacts make connections more reliable. |

Strong Build | Tough materials and designs handle stress and last longer. |

Strain Relief | Spreads out stress to avoid damage during use or setup. |

Pick connectors with the right materials and features for your vehicle. This ensures they work well and last a long time.

Top-Rated Harness Connectors for Heavy-Duty Applications

Deutsch Connectors: Features, Pros, and Cons

Deutsch connectors are trusted for tough vehicle jobs. They work well in extreme conditions. Made from strong, fireproof materials, they last in rough places. Silicone seals keep water out, and their design makes them durable.

Key features include:

Handles temperatures from -55°C to 125°C.

Water-resistant with IP68 rating, blocking moisture and salt.

Strong build resists shaking and avoids failures.

Protects against dust, dirt, and other particles.

These connectors keep electrical systems working in harsh environments. They are great for construction and farming vehicles.

Weatherpak Connectors: Features, Pros, and Cons

Weatherpak connectors are high-quality and reliable. They are made to keep water and dirt out, lasting a long time. Their small size makes them easy to install.

Advantages include:

Lightweight and compact for simple setup.

Resists moisture and rust.

Works with many vehicle wiring systems.

But their small size may not suit high-power needs. Still, they are a top pick for light and medium-duty vehicles.

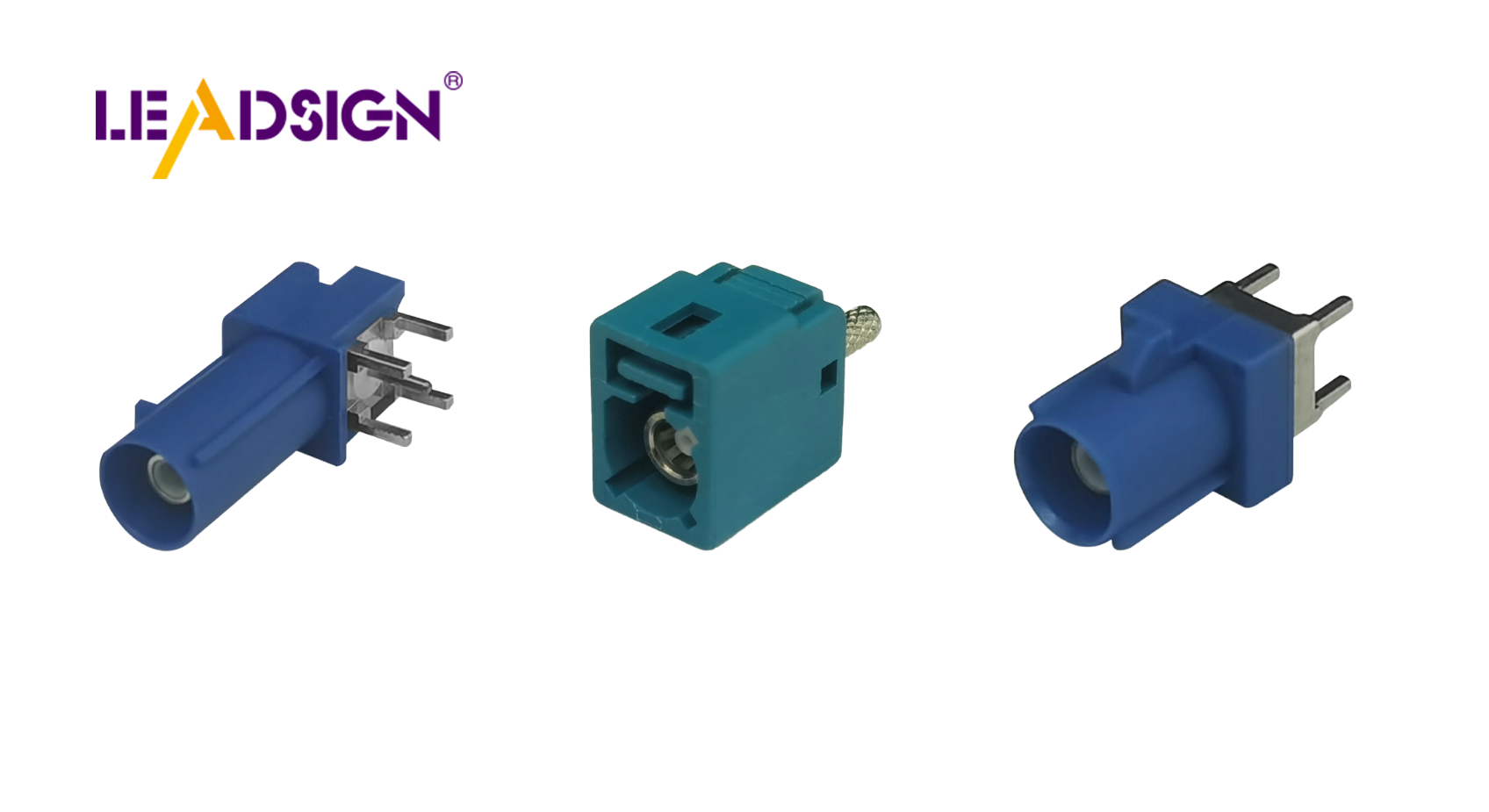

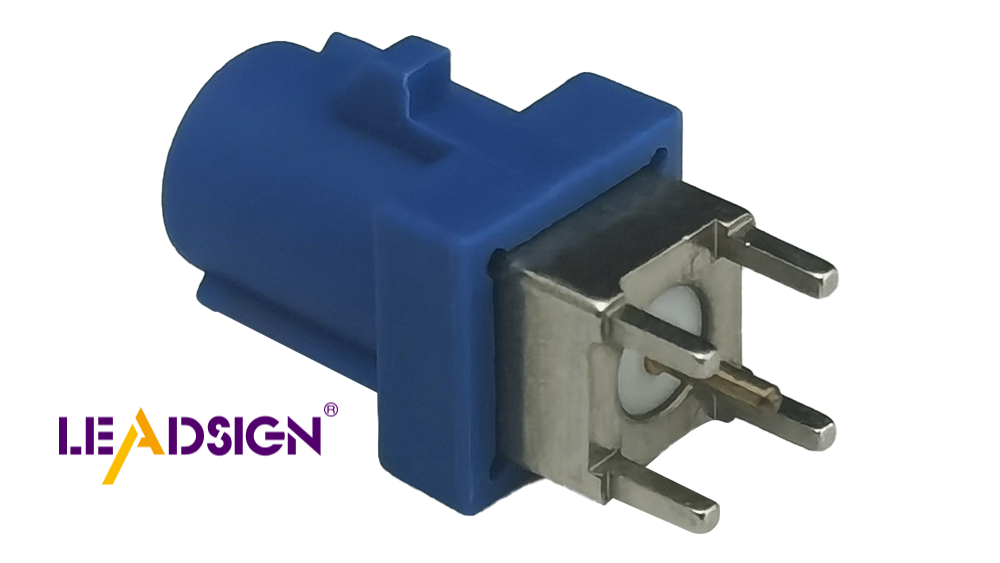

LEADSIGN FAKRA Connectors: Features, Pros, and Cons

LEADSIGN FAKRA connectors are fast and reliable. They use strong materials and reduce signal problems. These connectors are great for modern vehicle systems.

Notable features include:

Supports fast data up to 8 Gbps.

Works in temperatures from -40°C to +105°C.

Waterproof options for extra strength.

Compact designs save space and connect quickly.

LEADSIGN connectors are faster and better than older ones. They are perfect for GPS and entertainment systems, saving money over time.

Comparison of Top Connectors (Performance, Cost, Durability)

When choosing, think about strength, design, and environment. Deutsch connectors are the toughest for hard conditions. Weatherpak connectors are affordable and good for moderate use. LEADSIGN FAKRA connectors are best for high-tech systems needing speed.

Connector Type | Performance | Cost | Durability |

|---|---|---|---|

Deutsch | Great for tough jobs | Medium | Very strong |

Weatherpak | Good for light use | Low cost | Fairly strong |

LEADSIGN FAKRA | Best for tech systems | Worth it | Very strong |

Pick the connector that fits your vehicle’s needs best. This ensures your electrical system works well.

Testing and Validation Standards

Industry Standards for Durability Testing

Always check if connectors follow important industry rules. These rules make sure connectors are strong and work well. They also help companies make safer and better products. Some key rules are:

Standard | Use |

|---|---|

ISO 10487 | For car radio connections |

ISO 7736 | For installing radios in vehicles |

ISO 9458 | For motor connections in passenger cars |

By using these rules, you know the connectors will work well. This keeps driving safe and avoids electrical problems.

Ways to Test Reliability in Tough Conditions

Testing shows how connectors handle hard situations. These tests copy real-life challenges to check their strength. Common tests include:

Look for visible damage or problems.

Check if electricity flows without stopping.

Test insulation to see if it handles high voltage.

Use high voltage to test connector strength.

Shake and stress connectors to test durability.

Test in heat, cold, or wet conditions.

Check if they handle electrical loads properly.

Test how they work in real-life situations.

These tests make sure connectors stay safe and work well in tough conditions.

Certifications to Check When Picking Connectors

Certifications prove connectors meet strict safety and quality rules. Look for RoHS, which means no harmful materials are used. WEEE shows the product can be recycled, helping the environment. ELV ensures the connector is safe for vehicles. These certifications mean the connectors are high-quality, safe, and eco-friendly.

Future Trends and Innovations

New Materials for Better Connectors

New materials are making connectors stronger and more useful. Silver and silver-plated connectors send signals better with less loss. This makes them great for high-tech systems. Stainless steel and special composites stop rust and handle tough conditions. These materials help connectors last longer in harsh places.

Smaller connectors are also becoming popular. Liquid silicone rubber and heat-resistant plastics make tiny connectors that still work well. These save space but keep doing their job. Eco-friendly materials like recycled plastics are also being used more. They cut down waste and help the environment. Cool materials like shape-memory alloys and self-healing plastics add new features. They make connectors more reliable and flexible.

Smart Connectors and IoT Features

Smart connectors are changing how vehicles work. They use advanced materials like shape-memory alloys to stay strong. Self-healing plastics fix small damage, keeping connectors working longer. With IoT, connectors now help with data-sharing systems. They need to be light and tough to handle these tasks.

These smart connectors improve safety by giving real-time updates. For example, they can check connections and warn about problems early. This helps keep vehicles running safely and smoothly.

Eco-Friendly and Green Designs

Making connectors eco-friendly is now a big focus. Companies use recycled and bio-based plastics to make greener products. These materials lower waste and support cleaner production methods. Choosing these connectors helps the planet without losing quality or safety.

New designs also aim to save energy during production. Lightweight materials reduce fuel use in vehicles, helping the environment even more. These changes make connectors better for modern needs while protecting nature.

Picking strong and reliable connectors is very important. They help things work well, need less fixing, and avoid problems.

Easy Tips for Picking the Best Connector

Factor | What to Look For |

|---|---|

Handles Movement | Choose ones that lock and reduce shaking damage. |

Wire Connection | Make sure wires connect properly for good signals. |

Material Choice | Use metal for tough jobs or plastic for lighter tasks. |

Signal Quality | Pick connectors with low resistance and good materials. |

Fits with Systems | Get connectors that work with common setups. |

Learning about new ideas like smart and green connectors keeps you ready for changes and ahead in the market.

FAQ

What makes a harness connector suitable for heavy-duty vehicles?

A strong connector handles heat, water, and shaking well. It is made from tough materials like copper alloys. Secure locks keep it working in hard conditions.

How do you choose the right connector for your vehicle?

Think about where it will be used and its power needs. Check if it fits your system and has features like waterproofing. Look for safety certifications like RoHS.

Why are certifications important when selecting connectors?

Certifications prove the connector is safe and high-quality. They show it lasts long, follows rules, and is eco-friendly. This helps you trust your choice.

See Also

Benefits of HFM Connectors for Automotive Applications

Significance of HSD Connectors in Automotive Systems

Crucial Role of FAKRA Connectors in Automotive Use

Understanding the Advantages of Fakra Connectors in Cars

Boosting Data Transfer: Significance of High-Speed Connectors