Top Automotive Electrical Connectors Types Revealed

In cars, automotive electrical connectors types are very important. They help the car's electrical parts work well. These connectors face tough conditions like heat and liquids. They need strong locks to stay connected during vibrations. Good sealing is needed for those outside. Picking the right connectors keeps your car working safely. Strong connectors keep your car's electrical system in good shape.

Categories of Automotive Electrical Connectors Types

Knowing different automotive electrical connectors types is key for your car's electrical system. Each type has a special job and benefits.

Connectors by Sealing Capabilities

Sealing is important for connectors in tough places. These keep water and dirt away from connections.

AMP Superseal Connectors

AMP Superseal Connectors are made for sealed uses in cars. They are strong and handle hard conditions well, like water and dust areas. They stay connected even when it's tough outside.

Weather Pack Connectors

Weather Pack Connectors are cheap but seal well. Many use them in car projects because they block water and dirt. They are easy to put together or take apart, which helps with fixing things.

Connectors for High-Speed Data Transmission

Modern cars need fast data moving parts. These connectors help parts talk quickly to each other.

HSD Connector

The HSD Connector is made for fast data in car electronics. It works with cameras, USBs, and more. It's also good for digital entertainment systems, keeping cables tight.

Molex MX150 Connectors

Molex MX150 Connectors fit car wiring needing seals. They stop water and dirt, keeping data flow steady. Use them in many car systems to boost performance.

Connectors for Specific Applications

Some connectors meet strict needs of certain car parts, working best where they're used.

Engine Components

Engine part connectors handle heat and shaking well. Delphi Metri-Pack Connectors work here, giving strong links in harsh spots so engines run smoothly.

Infotainment Systems

Infotainment needs fast data links with clear signals. HSD Connectors fit these roles perfectly, linking entertainment systems inside cars smoothly.

High-Performance Environments

In high-stress spots, connectors must last long and work well. TE Connectivity DEUTSCH DT Series Connectors do this with great seals and strength, making sure your car's electric parts work even under stress.

By knowing these types and picking the right ones, you improve your car’s electric system’s function and safety.

Mechanical Properties and Benefits

Knowing how connectors work is key for your car. These traits show if connectors can handle stress and stay linked.

Crimp Connections

Crimp connections are important in cars. They have many good points.

Advantages of Crimp Connections

Crimping makes wires stick well to connectors. This stops rust and lasts long. It’s fast to put together, saving time on fixes.

Comparison with Soldered Connections

Crimps don't need heat, so parts stay safe. They fit many wire sizes too. Soldering might hold better but is harder to do right.

Cable Retention Force

Cable grip strength matters a lot for car connectors. It keeps them tight even when stressed.

Importance of High Cable Retention Force

Strong cable grip stops loose connections from shakes or hits. This keeps your car's electric parts working safely.

Examples of Connectors with High Retention Force, such as TE Connectivity DEUTSCH DT Series

Some connectors hold cables really well, like the TE Connectivity DEUTSCH DT Series. They work great in tough spots, keeping things connected under pressure.

By knowing these traits and picking the best ones, you make your car’s electric system last longer and work better.

To keep your car's electrical system working well, know the different automotive electrical connectors types. Each type has special uses and helps in different ways.

Sealing Needs: If there's water or dust, use AMP Superseal or Weather Pack connectors.

Data Flow: For fast data in infotainment systems, HSD connectors are best.

Strength: In tough places, pick strong connectors like TE Connectivity DEUTSCH DT Series for holding cables tight.

Choosing the right connectors makes your car safer and work better.

See Also

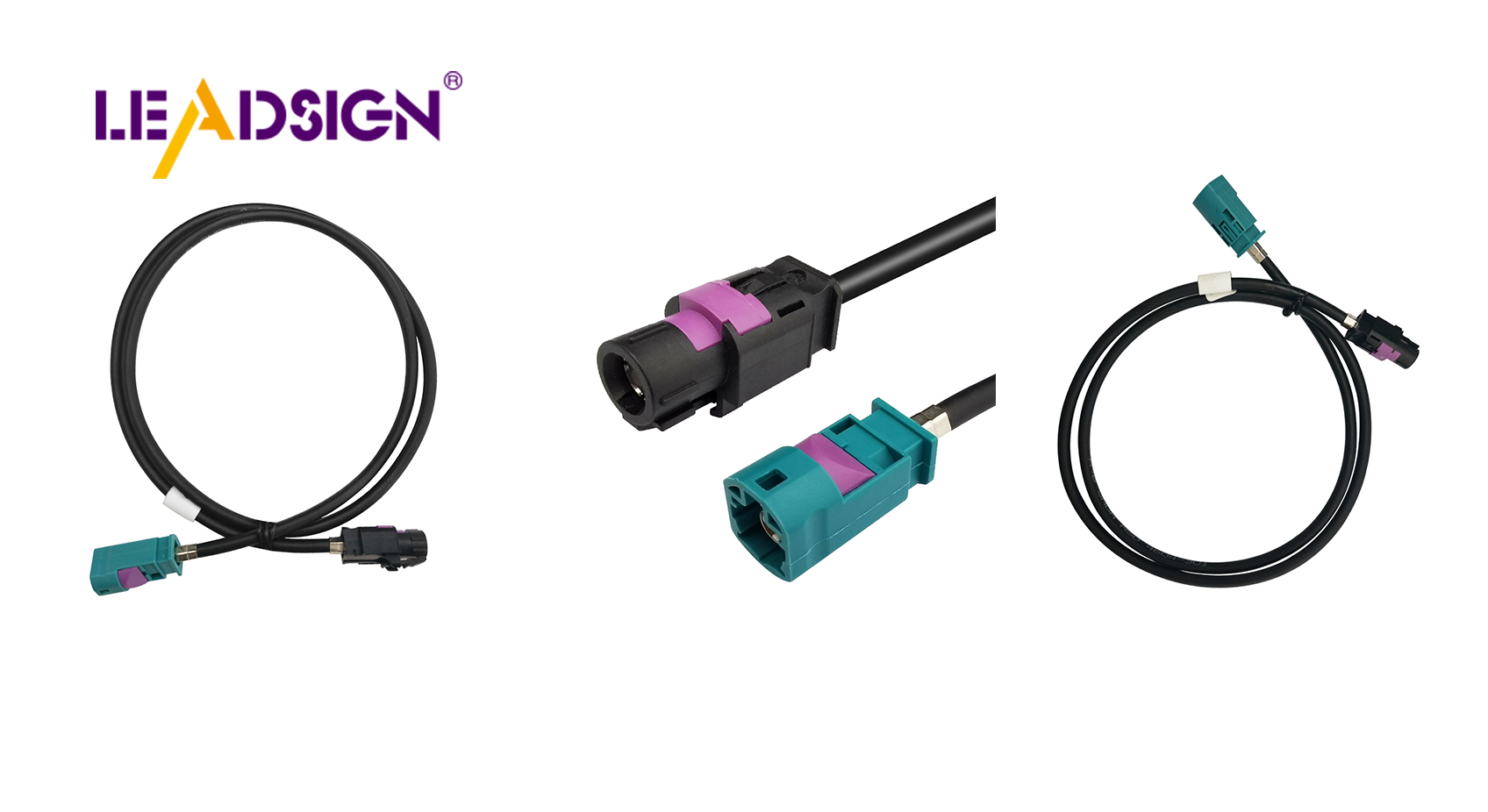

Decoding HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Maximizing High-Speed FAKRA-Mini Connectors in Auto Sector