Top Automotive Wiring Harness Connectors and Terminals for 2025

Car wiring connectors, including auto harness connectors, are important for keeping vehicles working well. They help different systems, like ADAS and EV parts, connect easily. As cars improve quickly, strong and reliable connectors are needed more. By 2033, the wiring harness market may grow to $121.3 billion. This growth is due to new ideas in EVs and ADAS. Picking the right connectors, such as auto harness connectors, helps your car work great, even in tough situations.

Key Takeaways

Pick strong connectors made of gold or tin-covered brass. These materials last long and stop rusting.

Use connectors with IP67 or IP69K ratings for water and dust safety. This keeps your car's wires safe in bad weather.

Think about your car's needs when choosing connectors. Match the wire size and power needs to stay safe and avoid overheating.

Key Features of Automotive Wiring Harness Connectors

Durability and Longevity

Strong connectors last long and work well over time. They are made with materials like gold or tin-coated brass. These metals help electricity flow and stop rust. Nylon and PBT are used for covers because they are tough. These materials also resist car fluids, keeping connectors safe.

To make sure they last, companies test them a lot. They check for cracks or flaws by looking closely. Tests also check if electricity flows properly through the wires. Insulation tests make sure the covers block electricity where needed. Other tests mimic real-life stress, like heat or heavy use.

Sealing and Weather Resistance

Car connectors must handle bad weather and stay dry. Special seals, like recessed ribs, block water and air. Many connectors meet IP67 and IP69K standards, meaning they resist water sprays. Testing rules, like USCAR2-7, ensure connectors work well in specific car systems.

Compatibility with Modern Vehicle Systems

New cars have many wires and connectors. Some cars use 700 connectors in 40 wire groups. These connectors link to systems like engines and radios. For strong power needs, like headlights, pin connectors are used. Locks keep connectors tight, even in big trucks.

Performance in Extreme Environmental Conditions

Connectors face heat, cold, and shaking in cars. Springs made of stainless steel keep connections steady in temperatures from -40°C to 140°C. Anti-shake designs and strong covers stop damage from bumps. These features help connectors work in any weather or road condition.

Top Automotive Wiring Harness Connectors and Terminals for 2025

TE Connectivity AMP Superseal 1.5 Series - Features and Applications

The TE Connectivity AMP Superseal 1.5 Series is small and reliable. It works well in tough conditions, making it great for cars, trucks, buses, and off-road vehicles. Its easy-to-use design helps with wiring and engine setup.

Feature | Description |

|---|---|

Small Size | Saves space in vehicle systems |

Strong Sealing | Works well in harsh environments |

Easy Assembly | Simplifies wiring and engine installation |

Uses | Fits cars, trucks, buses, and off-road vehicles |

Molex MX150L Sealed Connector System - Features and Applications

The Molex MX150L Sealed Connector System is flexible and useful. It’s often used in electric cars and other auto parts. Its smaller size makes assembly faster and lowers costs, which is helpful for commercial vehicles and electronics.

Industry Type | Application Description |

|---|---|

Automotive | Used in electric cars and many auto parts. |

Commercial Vehicles | Meets strict rules for mid-voltage wiring needs. |

Vehicle Electronics | Smaller size speeds up assembly and saves money. |

Yazaki 58 Series Connectors - Features and Applications

Yazaki 58 Series Connectors are strong and dependable. They are often used in car wiring to keep important systems connected. Their sturdy design handles high-performance needs, making them a top choice for today’s vehicles.

Delphi Metri-Pack 150 Series - Features and Applications

The Delphi Metri-Pack 150 Series is both tough and compact. These connectors work for low-energy circuits and handle up to 14 amps. Their sealed design keeps out water and dirt, making them great for engines and tough areas.

JST JWPF Series Waterproof Connectors - Features and Applications

The JST JWPF Series Waterproof Connectors are great at keeping water out. They are perfect for things like outside lights and engine sensors. Their small size and secure lock make them easy to use in tight spots.

Amphenol AT Series Connectors - Features and Applications

Amphenol AT Series Connectors are made for heavy-duty jobs. They are used in cars, farming, construction, and even military equipment. Their strong build ensures they work well in hard conditions.

Industry |

|---|

Automotive |

Heavy Equipment |

Farming |

Military |

Green Energy |

Furukawa Electric Aluminum Wire Harness Connectors - Features and Applications

Furukawa Electric Aluminum Wire Harness Connectors are lighter than copper ones. Aluminum cuts weight by 30%, making them easier to handle. They also save copper, helping protect resources.

Aluminum is 30% lighter than copper, reducing weight.

Easier to move and install, saving time and effort.

Works just as well as copper connectors.

Helps save copper for the future.

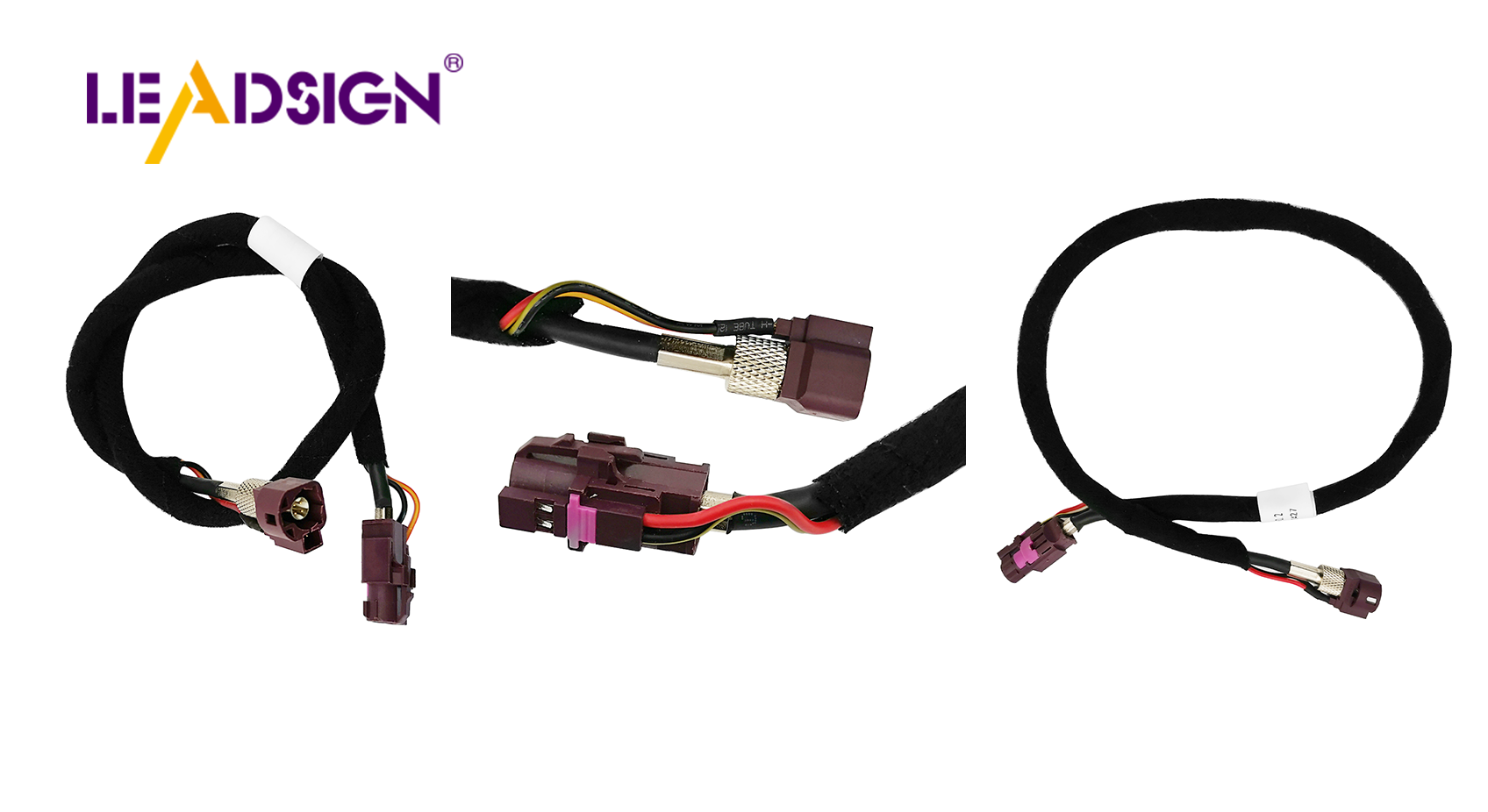

LEADSIGN HSD Connector - Features and Applications

The LEADSIGN HSD Connector is made for fast data transfer in cars. It supports systems like Apple CarPlay, Android Auto, and infotainment. It helps car electronics communicate quickly and smoothly.

Use Case | Description |

|---|---|

Infotainment System | Keeps car systems connected for better performance. |

Apple CarPlay Support | Sends data fast for using iPhone features in cars. |

Android Auto Support | Links Android devices to car systems easily. |

Digital Networks | Improves data sharing between car systems. |

Fast Data Transfer | Ensures quick and steady communication between devices. |

Z27C2 (2-Pin Connector) - Features and Applications

The Z27C2 (2-Pin Connector) is great for car lights like fog lamps. It comes ready with wires, terminals, and seals, making it easy to install. Its strong design lasts in different conditions.

Y11A1 (1-Pin Connector) - Features and Applications

The Y11A1 (1-Pin Connector) is small and dependable for single wires. It’s often used in low-power setups and gives a safe connection. Its simple design makes it easy to set up and use.

How to Pick the Right Connector or Terminal

Think About Wire Size and Current Needs

Start by knowing the wire size and current it can handle. Bigger wires carry more current without getting too hot. Use the American Wire Gauge (AWG) system to match the wire's strength to the power needed. If a connector is overloaded, it can overheat or fail. This might cause fires or system problems. Picking a connector that's too strong adds extra weight and cost. Always match the connector to your car's engine, lights, or other systems.

Check the Environment and Conditions

Car connectors deal with tough conditions like heat, cold, and chemicals. Think about things like temperature changes, water, and brake fluid exposure. Shaking and stress can also affect how they work. For example, light connectors must handle heat and cold while staying secure. Choose connectors with strong seals and materials to handle these challenges.

Make Sure It Fits Your Vehicle

Not all connectors work in every car. Makers design connectors for specific engines, lights, or power systems. Check that the connector fits your car's make and model. This ensures it works well with both high and low voltage systems.

Balance Cost and Quality

Good connectors may cost more but last longer. For low-power systems, cheaper options might work fine. But for important systems like lights, spending more on quality connectors is worth it.

Use a Checklist to Decide

A checklist makes choosing easier. Include things like connector type, pin count, and power capacity. Check if the housing protects against weather and if the contacts resist rust. For outdoor connectors, look at sealing needs. Also, think about grounding or shielding for electrical safety.

Tip: A checklist helps you pick the best connector for your needs.

Emerging Trends and Innovations in 2025

Use of Advanced Materials for Enhanced Durability

Car connectors in 2025 use better materials for longer life. Companies are switching from old materials like PVC to new ones like TPE and polyethylene. These materials last longer and are better for the planet. Some, like Yazaki Corp., use recycled plastics like Ecouse Toraycon. This recycled plastic is as strong as new but cuts carbon emissions. Choosing these connectors means they last longer and help the environment.

Miniaturization of Connectors for Compact Designs

Smaller connectors are changing how cars are built. Tiny connectors, like Molex Mini50, save 50% more space than older ones. This helps place ECUs in tight spots and use unused areas. Small connectors also work with zonal setups, linking parts by location. They cut weight, lower costs, and allow more sensors for ADAS. As cars get smarter, these designs save fuel and improve performance.

Small connectors make cars lighter overall.

They allow ECUs to fit in better places.

They free up space for EV battery systems.

Integration of Smart Features for Diagnostics

Smart connectors are now a big deal in cars. They check themselves for problems like overheating or low voltage. These features help find issues early, saving money and time. This is super helpful for EVs, where voltage must stay steady for safety. Smart connectors also keep EV batteries working smoothly, making them more reliable.

Focus on Sustainability and Eco-Friendly Materials

In 2025, being eco-friendly is very important. Companies use green materials to cut waste and pollution. For example, biodegradable covers replace old ones to avoid trash buildup. Yazaki and Toray Industries lead with recycled plastics like Ecouse Toraycon. These materials cut carbon emissions and match EVs' green goals. Picking these connectors helps the planet without losing quality.

Tip: Choose connectors made from recyclable or biodegradable materials to help the environment and support EVs.

Picking the right wire connectors keeps your car working well. The best 2025 connectors are tough and work in harsh conditions. They have features like strong seals, anti-shake designs, and heat resistance. Check brands like TE Connectivity or Amphenol for reliable choices that fit your car's needs.

FAQ

What does a wiring harness connector do?

It connects electrical parts in your car. This helps systems like lights, sensors, and radios work by sharing power and data.

How can I tell if a connector is waterproof?

Check for IP ratings like IP67 or IP69K. These show the connector can block water and dust, making it good for tough conditions.

Can one connector fit all cars?

No, connectors are made for specific cars. Always check if it matches your car's system to work correctly.

See Also

Enhancing Automotive Performance Through HFM Connector Usage

Understanding HSD Connectors Within Automotive Applications

Improving Data Transfer in Automotive With Advanced Connectors

Key Benefits of HFM Connectors for Automotive Solutions

Transforming Automotive Connectivity With HFM Connector Benefits