Top 3 Automotive Electrical Connectors Types You Need

Automotive electrical connectors are crucial in modern vehicles, ensuring reliable connections that enhance performance and safety. Understanding the various automotive electrical connectors types is essential for automotive work. The market for these connectors is rapidly expanding, projected to grow from USD 8.20 billion in 2023 to USD 26.11 billion by 2031. This growth underscores their increasing significance. As vehicles become more technologically advanced, the demand for robust connectors rises, making them indispensable in today's automotive industry.

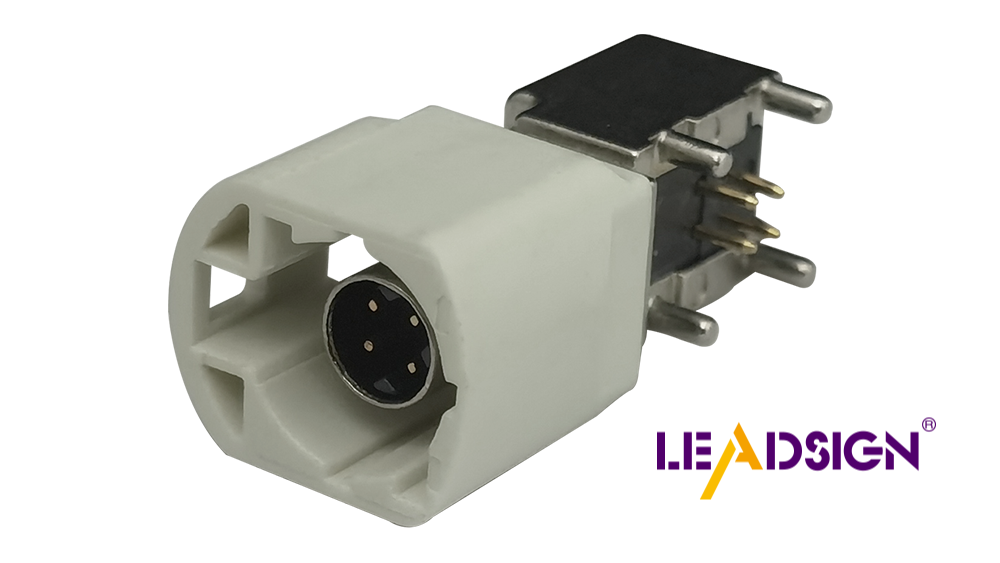

Type 1: High-Speed Data (HSD) Connectors

Applications

High-Speed Data (HSD) Connectors are very important in cars. They help with things like music and communication systems. These connectors connect parts like screens, cameras, and sound systems.

Specific automotive uses

In cars, HSD connectors are needed for fast data transfer. They work with LVDS, IEEE 1394, GVIF, eMOST, and USB 2.0. These connectors send data quickly in car electronics and networks. They are also key for smart driving systems where fast data is crucial.

Industry examples

The RosenbergerHSD® connectors show how useful HSD connectors are. They work with different cables for many car uses. You find them in camera links, USB ports, Ethernet, and Firewire setups. They stop interference from other signals to stay reliable.

Benefits

HSD connectors have many good points that make them popular among car connector types.

Reliability and durability

These connectors handle tough car conditions well. They keep working even when it's hard. Their design stops wrong connections from happening.

Cost-effectiveness

HSD connectors are strong but not expensive. They fit old systems too, saving money for car makers while still working great.

Standards and Certifications

Following rules is key to making sure car electrical parts are safe and good quality.

Relevant industry standards

HSD connectors follow important rules like the German AK HSD interface and USCAR 30 (Mini USB). These rules ensure they work well in cars safely.

Certification requirements

To be top quality, HSD connectors need UL and VDE certifications. These prove they are reliable for use in cars.

Type 2: Sealed Connectors

Sealed connectors are very important in cars. They keep wires safe from water, dust, and heat. These connectors are made to last in tough places, so they are needed in today's cars.

Applications

Specific automotive uses

Sealed connectors are used a lot in cars. They work where weather can be rough. For example, they go in engines, under the car, and outside lights. These connectors help brakes and control systems work well even when it rains or snows.

Industry examples

Big car companies use sealed connectors to make cars better. Companies like Aptiv and TE Connectivity make these strong connectors for electric and hybrid cars. They also work with smart driving systems because they are reliable.

Benefits

Reliability and durability

Sealed connectors are very strong and last long. They stop water from getting inside and rusting parts. This is important to keep car wires working safely.

Cost-effectiveness

Even though sealed connectors handle tough places, they save money too. Their strength means you don't have to replace them often. They fit with old car parts easily which saves more money.

Standards and Certifications

Relevant industry standards

Sealed connectors follow strict rules for safety and good work. They meet ISO 8092-2005 rules for car wires so they can handle hard hits and bad weather.

Certification requirements

To be sure they work well, sealed connectors need UL and VDE checks. These prove the connectors are good for cars, making makers and buyers feel safe using them.

Type 3: Unsealed Connectors

Unsealed connectors are used in cars where protection isn't needed. They make good connections in safe places. These connectors are part of many car types and are easy to use.

Applications

Specific automotive uses

Inside cars, unsealed connectors join parts like dashboards and lights. They help electronic parts talk to each other inside the car. Their design works where there's little dust or water.

Industry examples

Companies like Molex and Yazaki make these connectors for inside cars. They connect things like seat controls and climate systems. This shows how useful they are in different car parts.

Benefits

Reliability and durability

Unsealed connectors work well in safe spots. They keep connections steady without extra seals. They're made to be easy to plug in and take out.

Cost-effectiveness

These connectors save money for car makers. Their simple design is cheap to make, so they're great for inside cars. They fit with old systems, needing less change.

Standards and Certifications

Relevant industry standards

Unsealed connectors follow rules for safety and work well. They meet ISO 10487 standards for inside car use, showing they work right.

Certification requirements

To ensure quality, these connectors get checked by UL and VDE. This proves they're good for cars, making everyone trust them.

Picking the right car connector is very important. It helps cars work well and stay safe. Good connectors make systems reliable and stop problems. When choosing, think about weather, power, and how they fit. This keeps everything working smoothly and safely.

See Also

The Significance of Fakra Car Connectors in Contemporary Automobiles

The Value of FAKRA Connectors in Auto Uses

The Role of Fakra Connectors in Automotive Sector