Top 3 Automotive Electrical Connectors Types You Need

Automotive electrical connectors types are crucial components in modern vehicles. They facilitate communication between various parts, ensuring seamless operation. These connectors are specifically designed to withstand high temperatures, particularly in close proximity to engines where temperatures can exceed 150°C. Their reliable performance is essential for enhancing vehicle safety and efficiency. Additionally, they must be resilient against vibrations and user-friendly, especially in the context of electric vehicles. Due to frequent usage, robust designs are imperative to prevent issues. Well-crafted automotive electrical connectors types contribute significantly to the safety and reliability of automobiles.

Overview of Standards and Specifications

UL and VDE Standards

Importance in safety and reliability

UL and VDE rules are very important. They help keep car connectors safe. These rules tell makers what to do. This way, their products work well in tough car conditions. By following these rules, connectors can handle heat and shaking. They stay strong over time. This makes cars safer and builds trust in the product.

Key specifications

UL and VDE have key rules for connectors. Connectors must work at high heat, like 150°C near engines. They need to be strong against bumps and shakes while driving. Electrical parts should not lose power or signals. These rules make sure connectors are safe and work well.

USCAR, ISO, and SAE Standards

Role in automotive industry

USCAR, ISO, and SAE set quality rules for cars. They guide how connectors are made and tested. By using these rules, makers ensure parts fit different cars well.

Compliance requirements

To meet USCAR, ISO, and SAE standards, testing is needed. Makers test for strength against heat, shaking, and rusting. This shows that parts work safely everywhere. Meeting these standards helps sell products worldwide. compliance requirements

Top Automotive Electrical Connector Types

HSD Connector

Description and mechanical properties

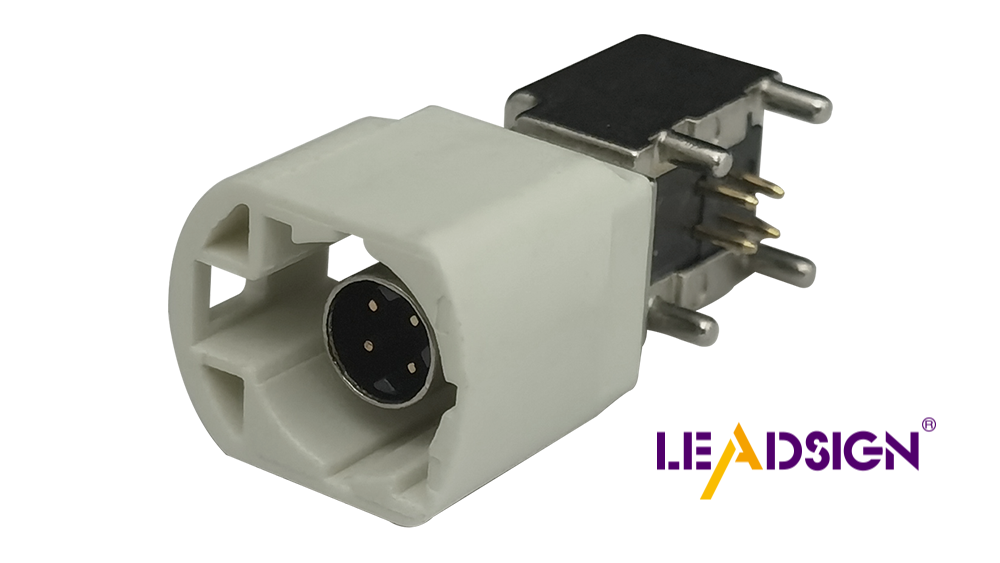

The HSD Connector is very important in cars. It helps send data fast without problems. It has a special 100 Ohm design that makes it work well. The connector has strong locks and holds cables tightly. This makes it great for tough car conditions.

Applications in automotive electronics

In car electronics, the HSD Connector is used a lot. It's needed for things like LVDS cameras, USBs, and IEEE 1394. It also helps with digital music systems and networks, keeping everything connected smoothly.

Unique features and advantages

The HSD Connector has cool features. It keeps data safe from outside noise. Its smart design stops wires from breaking easily. This makes it strong and easy to use in machines that build cars.

LVDS Connector

Description and mechanical properties

The LVDS Connector is another key type in cars. It sends data well with less interference from other signals. It's built to handle shaking and heat, working well even when it's tough.

Applications in automotive systems

Cars need the LVDS Connector for many uses. It's found in driver help systems, music players, and cameras. It sends data fast without losing signals, making it perfect for these parts.

Unique features and advantages

The LVDS Connector is small but powerful. It fits into tight spaces while carrying lots of power safely. Its strong build ensures it's safe to plug in again and again.

Ethernet Connector

Description and mechanical properties

The Ethernet Connector helps car parts talk to each other easily. It's made to handle heat and shaking well so it works reliably anywhere inside a car.

Applications in automotive systems

In cars, the Ethernet Connector is crucial for sharing information quickly between parts like telematics or infotainment systems.

Unique features and advantages

This connector prevents wrong connections with its smart design while holding cables firmly so they don't come loose.

Automotive connectors are vital for cars today. They keep us safe and make driving smooth. Picking the right ones is key for car safety and working well. These connectors must handle heat and power well to be reliable. As cars get smarter, better connectors are needed. Improving them helps sell more and grow the industry. Choosing good connectors is important for best performance.

See Also

The Significance of Fakra Auto Connectors in Contemporary Cars

The Value of FAKRA Connectors in Auto Uses

The Vital Role of Fakra Connectors in Auto Sector