Top 3 Automotive Electrical Connectors Types Compared

Automotive electrical connectors play a crucial role in vehicles, facilitating the safe and efficient connection of electronic components. The demand for these connectors is on the rise, with a projected growth rate of 6.7% from 2024 to 2030, underscoring their increasing significance in the automotive industry. Among the various automotive electrical connectors types, notable examples include the HSD Connector, DEUTSCH DT Series, and Molex MX150. Each of these connectors offers distinct advantages, positioning them as essential components in modern vehicles.

Overview of Automotive Electrical Connectors

Definition and Function

Automotive electrical connectors are key parts in cars. They help send electrical signals and power between different car parts. These connectors support modern car technology, allowing new features to work.

Role in Vehicle Electrical Systems

Connectors join electronic modules, sensors, and actuators in cars. They help the engine control unit talk to infotainment systems and safety features. Good connections keep the car working well.

Importance for Safety and Performance

Connectors are important for safety and performance. Cars need strong connectors for airbags and brakes. More plastic optical fiber cables show how connectors boost safety. Reliable connectors stop electrical problems, so safety systems work right.

General Types of Connectors

There are many types of automotive connectors for different uses. Knowing these helps pick the right one.

Criteria for Selection

When picking connectors, think about:

Durability: They should handle tough conditions like heat and shaking.

Compatibility: Must fit with OEM designs as noted by Eigen Engineering.

Safety Standards: Must meet strict rules, especially in Europe.

Common Challenges and Solutions

Connectors can rust or wear out. To fix this, makers use better materials and designs. Sealed connectors keep water out to stop rusting. Locking systems keep them connected even if shaken.

Top 3 Automotive Electrical Connectors Types

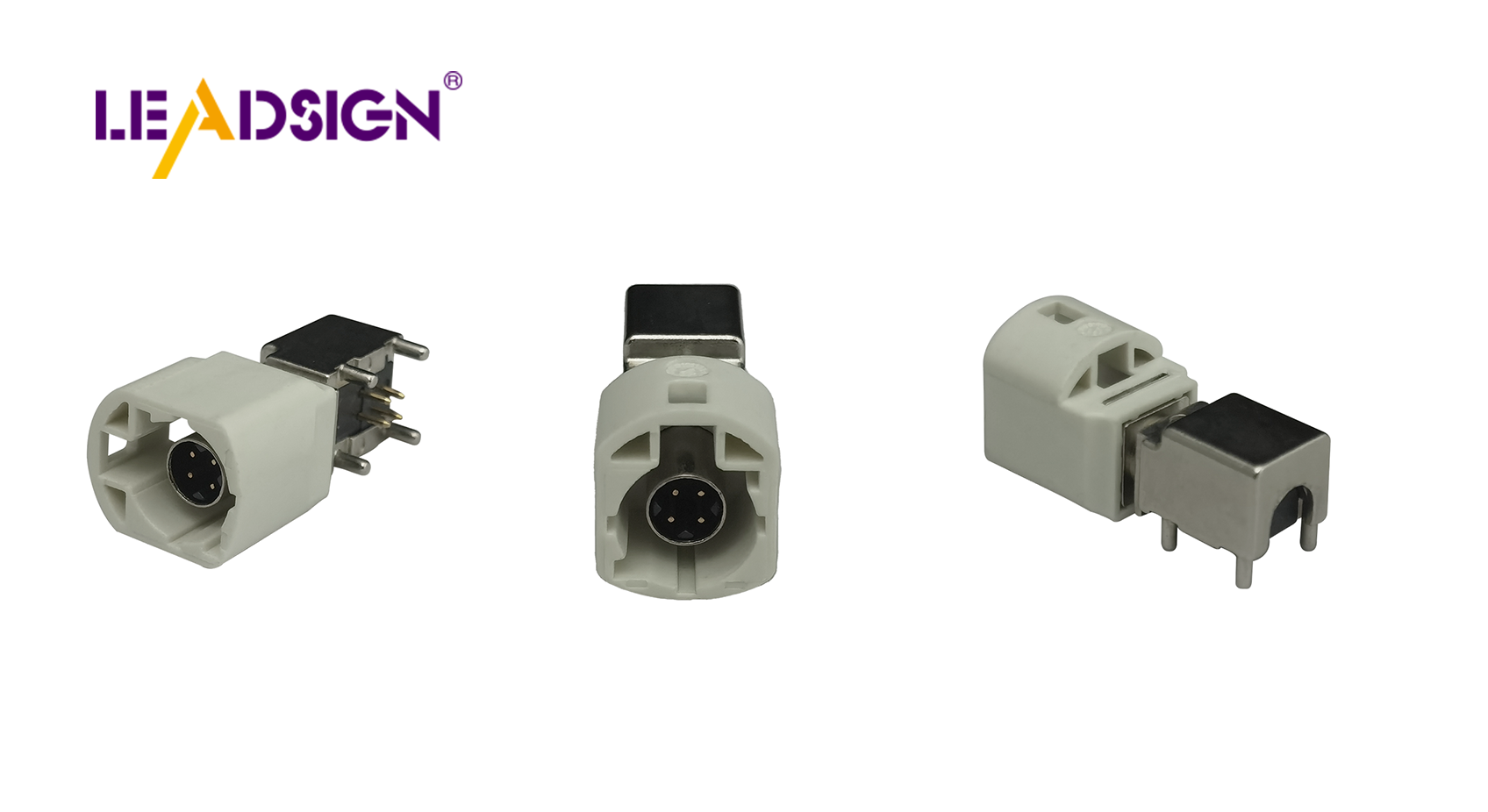

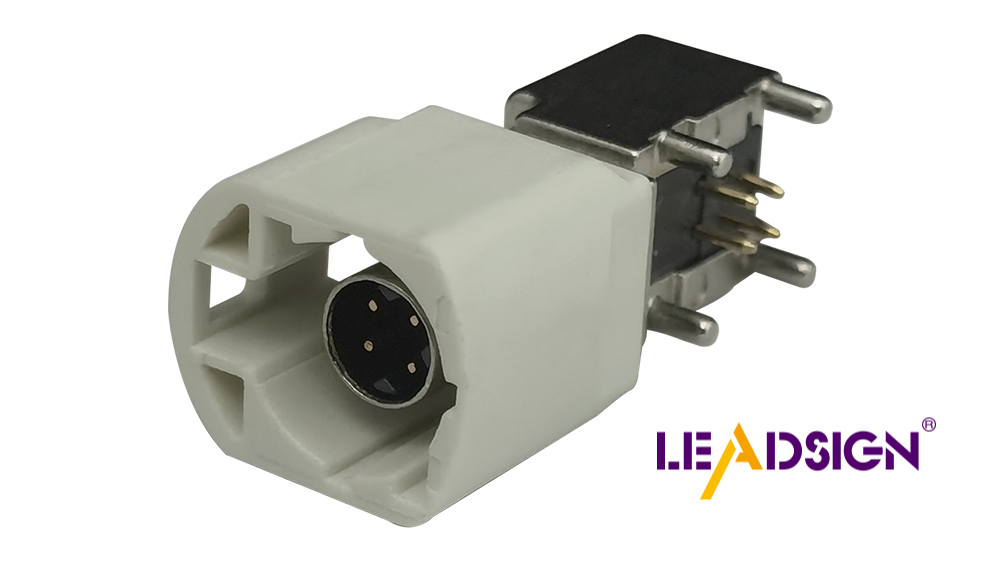

Type 1: HSD Connector

HSD Connectors are key in car electronics. They send data fast. They work well with cameras, USBs, and Firewire.

Mechanical Properties

Primary and Secondary Lock: Keeps connections tight.

Crimp Connection: Makes strong electrical links.

High Cable Retention Force: Stops cables from coming loose.

High Coding Efficiency: Different codes stop wrong connections.

Applications

Car electronics

Radio stations

Infotainment systems

Networks

USB versions 1 to 3

Ethernet

Firewire (IEEE 1394)

GVIF

Leading Manufacturers

LEADSIGN: Known for cool designs in car electronics.

Amphenol: Famous for flexible circuit connectors.

TE Connectivity: Makes special products for car cameras.

Type 2: DEUTSCH DT Series

The DEUTSCH DT Series connectors are tough and last long. They are used in big trucks and building machines.

Mechanical Properties

Rugged Design: Handles tough conditions.

Sealed Construction: Blocks dust and water.

High Durability: Lasts a long time.

Applications

Big vehicles

Building machines

Farm equipment

Boats

Leading Manufacturers

TE Connectivity: Sells many DEUTSCH connectors.

Mouser Electronics: Ships DEUTSCH products worldwide.

J.S.T. Mfg Co. Ltd: Known for good car connectors.

Type 3: Molex MX150

Molex MX150 connectors are small and useful. They work inside or outside cars, even when wet.

Mechanical Properties

Compact Design: Fits in small places.

Waterproof: Good for outside use.

Robust Construction: Works well over time.

Applications

Signal lights

Motor controls

Side mirrors

Blind spot sensors

Leading Manufacturers

Molex Incorporated: A top name in car connector tech.

Yazaki Corporation: Offers many vehicle connectors.

D.R. Company: Supplies car electrical parts.

Comparing Connectors

Important Comparison Points

Mechanical Features

When looking at car connectors, mechanical features are key. Each type has special traits that affect how it works in different places. For example, the HSD Connector holds cables tight and connects well. The DEUTSCH DT Series is tough and keeps out dust and water, perfect for rough spots. The Molex MX150 is small and waterproof, good for inside or outside cars.

Uses

These connectors have different uses too. The HSD Connector is great for fast data in car tech and infotainment. The DEUTSCH DT Series works best in big trucks and boats because it's strong. Meanwhile, the Molex MX150 fits signal lights and sensors due to its small size.

Maker Reputation

Who makes these connectors matters a lot too. Top makers like LEADSIGN, Amphenol, and TE Connectivity are known for good designs. TE Connectivity is famous for camera system parts in cars. Also, Molex Incorporated and Yazaki Corporation have many quality products that meet strict rules.

Special Traits and Benefits

Specific Examples

Each connector has special benefits for certain needs. The HSD Connector stops wrong connections with high coding efficiency, important for complex systems. The DEUTSCH DT Series protects against dust with sealed design, lasting long in hard places. The Molex MX150 fits easily into small spaces, ideal for new car designs.

Insights from Data

Data shows materials matter a lot for connector performance. Materials like X, Y, Z work well in tough spots or when used often. They make connectors last longer and stay reliable over time. Knowing this helps makers build better products that keep cars safe.

The blog looked at three main car connectors: HSD, DEUTSCH DT, and Molex MX150. Each one has special features and uses. They fit different car needs. When picking a connector, think about how it connects, where it will be used, and the power needed. Good connectors keep cars safe and working well. As tech gets better, strong connectors are more important because of new safety rules. Choosing the right connector makes cars last longer and helps with future car ideas.

See Also

Significance of Fakra Auto Connectors in Contemporary Cars

Fundamentals of HSD Connectors in Auto Sector

Benefits of HFM Connectors in Auto Sector